Electric vehicles are a revolutionary technology in the automotive space. They offer a new dimension to the traditional internal combustion engines. The vehicles run on electricity, requiring no need for fuel.

This article focuses on the different types of electric vehicles, exploring their features, working principles, benefits, and challenges. We also discussed the manufacturing processes used in creating parts for these automobiles. Let’s get right into it!

What is an Electric Vehicle?

What is an Electric Vehicle?

An electric vehicle (EV) is a car that runs on electricity. Unlike traditional cars that run solely by burning fuel, using an internal combustion engine, an EV uses an electric motor to generate electricity to power the car. However, some hybrid electric car types use electricity and fuel combustion.

These vehicles limit the production of exhaust fumes. Therefore, they are the next innovation towards reducing pollution and global warming, including promoting environmental conservation and sustainability.

Types of Electric Cars You Need to Know

There are several electric car types each having its peculiarities. This section will discuss the classification of these vehicles.

Battery Electric Vehicles (BEVs)

Battery electric vehicles are pure electric vehicles, sometimes called all-electric cars, because they run solely on electricity. Unlike traditional combustion cars, they don’t have an engine that can process fuel or gas. Instead, they depend on their rechargeable battery – often lithium batteries – to power the built-in electric motors. Therefore, these vehicles produce no emissions when driving but require routine charging to regain power.

This type of electric vehicle can use standard power grids in homes and public EV charging stations to recharge the batteries. However, to ensure fast charging, use outlets installed by the vehicle’s manufacturers or ones installed by qualified electricians specified for charging EVs. Besides charging, BEVs draw some power through the regenerative braking systems. The vehicle is designed to convert energy generated into electricity to power the car.

Standard features of a BEV include the electric motor, inverter, rechargeable lithium battery, drive train, and control module.

Working Principles of BEVs

Working Principles of BEVs

The operations of a standard battery electric vehicle follow the following process to ensure seamless driving.

As you turn on the ignition to start the car, the inverter converts DC power from the battery to AC. Upon pressing the accelerator to start driving, a signal is sent to the controller to propel the car into driving. This involves varying the frequency of the AC power that gets to the car’s motor. Afterward, the electric motor turns the car wheels through the car, causing the driving mechanism.

Benefits and Challenges of BEVs

Below are the benefits and challenges of battery-electric vehicles.

Benefits

- Zero Emissions: These vehicles are a step forward to reduce greenhouse effects and promote environmental sustainability.

- No Noise: Since these vehicles don’t use an internal combustion engine, they are quiet with little to no noise when driving – consequently, a smoother driving experience

- Low Maintenance: These vehicles may be much more expensive than general fuel-powered automobiles. However, they have fewer moving parts and no need for fuel. Therefore, there is a reduced operational and maintenance cost.

Challenges

- BEVs may experience limited range, requiring more than one charging for long travels.

- Availability and accessibility of charging stations are another challenge.

Typical examples of electric vehicles of this form include MG ZS, TATA Nexon, TATA Tigor, Mahindra E20 plus, Hyundai Kona, and Mahindra Verito.

Plug-in Hybrid Electric Vehicles (PHEVs)

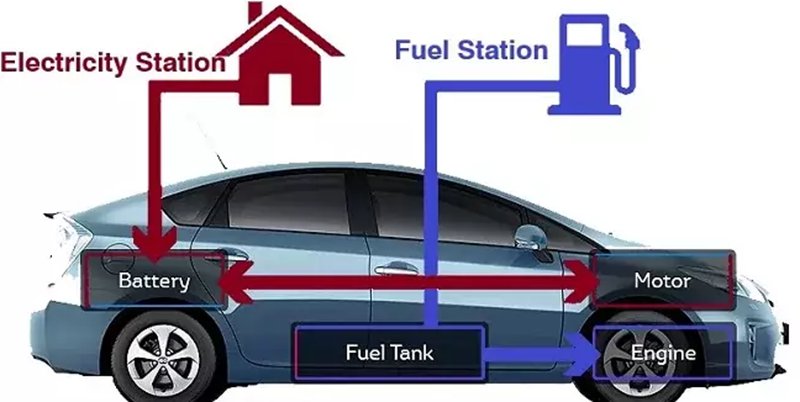

As the name of this vehicle suggests, these types of electric cars use a combo of standard electric motors and fuel-powered engines. Therefore, for plug-in hybrid electric vehicles, you can recharge the batteries in traditional power outlets or public charging stations to power the engines or use fuel, which may be gasoline or alternative fuel like biofuel. This dual-power system is the main distinctive characteristic of these automobiles.

These hybrid electric car types can travel longer distances because of the dual energy source. Like the BEVs, the PHEVs also benefit from regenerative braking systems to recharge the battery.

The vehicle features the same components as the BEVs: an electric motor, rechargeable battery, inverter, control module, and if it’s an onboard model, a battery charger. However, it also has a fuel tank and an internal combustion engine for switching to fuel power.

Working Principles of PHEV

Working Principles of PHEV

While these types of vehicles operate a dual-power system, they generally start with the all-electric mode, using energy from the electric motor and battery. The car only switches to the fuel engine system after draining the battery. Then, it starts to operate as a typical internal combustion engine.

Recharging the drained battery is similar to the BEVs, where you can plug in a power outlet or public charging stations. However, we must mention that the internal engines of these vehicles are generally smaller than the typical combustion engines because the electric motor supplements their function. Moreover, the smaller engine enhances fuel efficiency and maintains optimum performance.

List of EVs in this group include Porsche Cayenne S E-Hybrid, Volvo XC90 T8, BMW i8, Hyundai Sonata, Ford Fusion Energi, Mercedes S550e, Chevy Volt, Kia Optima, Audi A3, etc.

Benefits and Challenges of Operating a PHEV

The benefits and challenges of operating plug-in hybrid electric car types include the following.

Benefits

- The vehicles can cover longer traveling distances, thanks to the additional internal combustion engines, which kick-start after exhausting the electric power.

Because the combustion engine is supplementary, the vehicles still help reduce emissions, contributing to a conservative environment. Moreover, the engines have enhanced burn fuel better to prevent altering performance.

PHEVs serve as a transitional technology, providing users with a dual-power engine. This benefits individuals who are not fully committed to switching to electric power.

Challenges

- Because of the sophistication of the vehicle’s system, they are challenging to manufacture and expensive.

- Maintenance of these vehicles may be challenging because of their complexities.

Hybrid Electric Vehicles (HEVs)

Like the PHEVs, hybrid electric vehicles (HEVs) utilize dual power from the internal combustion engine and an electric motor. Consequently, they are sometimes called series hybrid or parallel hybrid. These types of electric vehicles rotate between the engine power and the electric motor when driving.

The main distinction from the PHEVs is that they do not support plug-in recharge. However, it also benefits from the regenerative braking system of typical EVs, like the BEVs and the PHEVs. The HEVs share components similar to the PHEVs – the engine, electric motor, battery pack with controller, fuel tank, inverter, and control module.

Working Principles of the HEV

Working Principles of the HEV

The car basically functions based on the electricity or the internal combustion engines. The fuel tank supplies energy to the car like a regular car, while the electric motor draws power from the battery, which is recharged through the braking system. As you drive, there’s a continuous rotation between the electric and the car’s fuel system in the vehicle’s operation. However, the car switches solely to the fuel system if there’s no electric power.

The list of EVs in this class includes the Toyota Prius, the Chevrolet Volt, the Honda Clarity Hybrid, and the Ford Fusion Hybrid.

Benefits and Challenges of HEVs

Below, we discuss the benefits and challenges of hybrid electric vehicles.

Benefits

- Like the PHEVs, HEVs offer better fuel efficiency with reduced emissions, promoting environmental conservation.

- You do need to routinely recharge the vehicle’s battery, as the recharging is mainly through the braking system.

- Longer driving distance, as it can switch to a fuel system when there’s insufficient battery capacity.

Challenges

- It does not support complete electric driving.

Fuel Cell Electric Vehicles (FCEVs)

The fuel cell electric vehicles represent a new innovative approach to sustainable transportation. These types of electric vehicles operate on a continuous electrochemical reaction with hydrogen and oxygen fuels. It uses fuel cell technology to generate electricity to power the electric motor. So since they run on electricity, there’s no emission. However, they are relatively new and not yet available for daily use.

The main components of the FCEvs are the electric motor, battery with converter, controller, hydrogen storage tank, and fuel-cell stack.

Working Principles of FCEVs

Working Principles of FCEVs

The vehicle uses the fuel cell tech to generate the electricity to drive itself. The fuel cell stack combines the stored hydrogen with oxygen from the air to produce electricity through an electrochemical technology. This electricity drives the vehicle, producing water vapor as its by-product. Therefore, this vehicle has no emissions, unlike the exhaust fumes of standard combustion engines.

Examples of electric cars in this class include the Hyundai Tucson FCEV, Toyota Mirai, Honda Clarity Fuel Cell, and Hyundai Nexo.

Benefits and Challenges of FCEVs

This section discusses the benefits and challenges of operating fuel-cell electric vehicles.

Benefits

- There’s no production of any fumes or emissions, with water as the bus product.

- Since it uses hydrogen, refueling the car is quicker than traditional vehicles, including BEVs, requiring routine recharging.

- Using this vehicle is a step towards promoting environmental conservation and sustainable energy.

Challenges

- There are limited hydrogen refueling stations

- The manufacturing process is complex, expensive, and challenging.

Customization and Manufacturing of Electric Car Parts

Different manufacturing processes are suitable for manufacturing and customizing electric vehicle parts. Custom fabrication allows the creation of new innovative designs for these vehicles without losing sight of features such as precision and adaptability to specific design requirements. The processes will enable manufacturing parts and components to be tailored to suit the particular needs of EVs and promote efficiency and performance.

Below, we will explore the standard manufacturing methods for these applications.

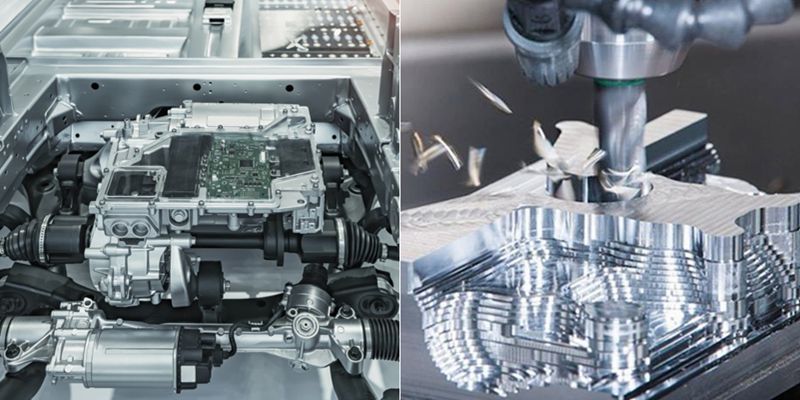

CNC Machining

CNC Machining

CNC automotive machining is a process for manufacturing no-standard EV parts because of their ability to create and shape parts with high precision and dimensional accuracy. The manufacturing technique uses computer codes to control a series of cutting tools as they restructure a workpiece to suit your requirements. The operation is suitable for creating EV components like battery casings, motor parts, car gearboxes, rotary shafts, and ball bushings.

Die Casting

Die Casting

Die casting is another important manufacturing method suitable for creating EV parts, including those with complex shapes. The process involves heating metals to the molten state, then injecting them into a premade die cavity where they form your desired shape and structure. The technique is suitable for creating motor housings, structural elements, and heat sinks.

Injection Molding

Injection molding is a popular technique for manufacturing electric vehicle plastic parts, especially for its cost-effectiveness in manufacturing bulk volumes. However, it is also suitable for creating rare structures and custom EV components. The technique involves heating engineering-grade plastics and then forcing the molten plastics into a mold cavity, where it solidifies into your design shape.

Since it creates plastic parts, it is a good choice for creating lightweight and lighting components, such as light pipe designs and the EV battery box design. It is also suitable for creating interior features like dashboards and other housing components, including exterior components like bumpers.

3D Printing

3D printing uses additive manufacturing technology to manufacture and customize EV parts. The process uses a 3D printer, which uses powdered and filament to build the components in layers till the final shape, structure, and size of your intended fabrication are achieved.

It is the go-to process for rapid prototyping and testing of custom intricate designs for their suitability and adaptability for their intended applications. The technique is suitable for creating complex car prototypes with high precision, including interior components and structural features.

Sheet Metal Fabrication

Unlike other methods, sheet metal fabrication is not really a manufacturing method. As the name suggests, it involves creating parts and components from metal sheets. The technique combines a series of cutting, bending, machining, and assembling operations to make these components. Therefore, it is beneficial for manufacturing and customizing EV parts. Typical applications include manufacturing structural elements like the chassis and trim components.

The Role of Prototyping in Manufacturing Electric Vehicle Parts

The Role of Prototyping in Manufacturing Electric Vehicle Parts

Regardless of the manufacturing process you use to create parts for electric vehicles, prototyping plays a crucial role. The concept of the automotive design process starts from having an idea through prototyping and then to the actual fabrication. The prototyping stage is influential in maintaining precision, functionality, and efficiency.

Creating prototypes helps OEMs run quality tests to ensure the part suits its intended applications. It allows engineers and designers to test and refine new concepts before mass production, reducing errors and performance optimization risks. Therefore, it ensures the part suits the fit and function of which it’s intended.

Future Trends in Electric Vehicle Manufacturing

The future trends in electric vehicles are targeted at making significant advancements to enhance car efficiency and performance. Below are possible trends to fit into this profile.

- Increase in battery energy density to increase driving distance with electricity;

- Use of more sophisticated materials like graphene in manufacturing EV parts and components;

- The integration of artificial intelligence to promote autonomous driving capabilities and energy management;

- Collaboration with car and OEMs to integrate intelligent features and improve connectivity.

AutoProtoWay: Your Partner for Custom Electric Vehicles Parts

Even with the knowledge and skill to manufacture your electric vehicle parts, a practical approach is to employ a reputable service provider for your project. This helps you to reduce costs without compromising quality. AutoProtoWay is an expert in offering custom car prototyping, automotive parts manufacturing, and finishing solutions for your projects.

We guarantee industry-standard services that cut across various processes, including CNC machining, injection molding, 3D printing, die casting, and other related technologies. While maintaining high-quality solutions, we do this at competitive pricing with a quick cycle time. Just upload your files to get a free quote!

Conclusion

Electric vehicles are already gaining popularity, as many are switching to these innovative and more efficient automobiles. However, not all electric cars run solely on electricity; some switch between fuel systems and electricity. We already discussed the different types of electric vehicles, including their peculiarities. Still, there are plans for more futuristic approaches to enhance these cars.

FAQs

What battery is used in electric vehicles?

The predominant battery used in electric vehicles is the lithium-ion battery. They are high-density batteries capable of powering the electric motors and providing sufficient energy to drive the car.

What is an electric vehicle called?

An electric vehicle is called an EV – the acronym. However, some may call it an electric car. Either name refers to all examples of electric cars, including battery electric vehicles, plug-in hybrid electric vehicles, hybrid electric vehicles, and fuel-cell electric vehicles.

What are the challenges to manufacturing fuel-cell electric vehicles?

While fuel-cell electric vehicles are the newer EVs, they have some manufacturing difficulties. The main challenge is the limited hydrogen refueling infrastructure. This technology requires intense capital due to its complexities. Moreover, the vehicles are still limited, as they have yet to be widespread, compared to other EVs, talkless of traditional vehicles.