A keen advancement in part manufacturing technology in the automotive industry is responsible for the industry’s recognition as a major economic force globally. Before the introduction of automation and the rise in the popularity of parts made using CNC automotive machining, part manufacturing was majorly by hand. However, we now have several automotive part manufacturing processes of which CNC machining is popular.

CNC machining is a transformative process that plays an important role in the automotive part manufacturing industry. This article will introduce the role and applications of CNC machining in the automotive industry, its advantages, and the future trend of the process.

What is the Important Role of CNC Machining in the Automotive Industry?

CNC machining plays an important role in the prototyping and manufacturing of automotive parts. As a prototyping process, it allows manufacturers to make prototypes which allows them to see possible flaws in the design. With this, manufacturers can keep up with the design requirement while avoiding flaws that can affect such parts’ functions. It is also suitable for the actual production of such parts.

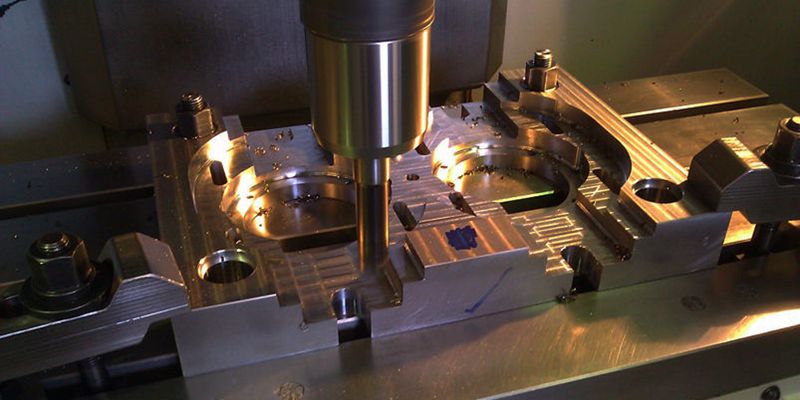

CNC automotive machining comprises several operations such as CNC turning, milling, drilling, etc., compatible with metals, plastics, and composites. These operations are suitable for making complex car components such as the engine, lighting, gearboxes, etc., due to their precision, accuracy, and repeatability.

Advantages of Using CNC Machining for Automotive Parts

Below are a few advantages of CNC auto parts machining:

Automation

Automation is a CNC machining quality that allows automotive companies to manufacture parts without human interference.

Consequently, it is easier for manufacturers to focus on innovations and design.

The focus of manufacturers on design and innovation ensures that the CNC car parts have better designs and functions. Also, the fast process makes it easy for manufacturers to break into the market and compete.

Speed

CNC automotive parts are made at high speed because CNC machines rely on computer instructions with little or no human involvement. Therefore, human factors such as fatigue can affect the machining operation.

As a result of its high speed, the process is the perfect option for large-volume part manufacturing.

Accuracy and Precision

Accuracy and Precision

Automotive parts majorly have complex designs and require tight tolerances. This is because manufacturers majorly assembled them to form different products after part manufacturing. For example, a car’s piston rings have a tolerance of about 4 μm and must fit in a corresponding cylinder.

Making these parts is impossible using hand, and other machining processes cannot deliver like CNC. Hence, CNC machining is the most suitable process because of its precision, accuracy, high tolerances, and ability to make parts with complex designs. It is also computer-controlled. Hence, there is no human error.

Repeatability

Automotive part manufacturing requires a process with high repeatability due to the large volume of production. CNC machining is, therefore, a suitable process because it is computer controlled. Being computer-controlled and having high accuracy ensures the fabrication of parts without any discrepancy.

Production Applications of CNC Machining for the Automotive Industry

CNC automotive machining helps in making several parts in the automotive industry. Called CNC car parts, these parts are highly accurate for easy assembling to form different automotive products. They include:

Interior Panels

Interior Panels

CNC machining is applicable in making interior panels component such as the dashboard. The dashboard comes from plastic or wood (for exotic cars). It has a complex design with space that must fit the speedometer, gas gauge, radio, indicator light, and other components.

CNC machining operations such as milling and drilling are perfect for such components because such cutouts should have a high tolerance that doesn’t affect the functional properties of the part after assembling.

Starter Motors

The starter motor is a metal part that rotates the internal combustion engine. It has a complex design and requires a manufacturing process with a very high tolerance. CNC machining is the perfect method for such CNC car parts due to its precision, accuracy, and tight tolerance, which allows proper optimization of the parts.

Cylinder Heads

Cylinder Heads

Cylinder heads are majorly aluminum materials that are highly machinable and cover the internal combustion engine. Alongside the cylinder head, you can machine similar CNC car parts with limited runs or customizable engine models such as alternator housings, brake system valves, and fuel pump systems.

Drive Axles

Drive Axles

Another CNC car part is the drive axle. The drive axle comprises two half axles connected to a wheel by a joint. It has a critical part that enables free movement and high precision parts such as the hypoid and bevel gears. Due to its sophistication, it requires a highly accurate manufacturing process such as CNC machining.

Gearboxes

Gearboxes

The gearbox comprises various shafts and gear components that increase the car’s torque and speed. Due to the design, CNC automotive parts machining operations such as drilling, milling, and turning are applicable in making such parts.

Lighting

Lighting

CNC machining is suitable for working with materials such as acrylic glass and PMMA used in car lighting. Hence, lighting components such as headlights and interior lighting are compatible with the process—however, other surface treatments such as grinding and polishing for better aesthetic value.

What is the Trend in Automotive CNC Machining in the Future?

The basic principle regarding automotive part manufacturing is the same. However, innovation continues. This is visible in the continuous incorporation of fresh approaches and innovation into automotive part design and production. Here are the top trends in automotive CNC machining in the future.

Advanced Materials for Improved Performance

Advanced Materials for Improved Performance

Currently, automotive part manufacturers now use various techniques to make car lighters for improved and efficient performance. For example, most manufacturers now use lightweight materials such as aluminum in part manufacturing. These materials replaced the traditional materials and are compatible with CNC machining due to their high machinability. Consequently, the car becomes lighter and faster.

Artificial Intelligence in CNC Automotive

CNC machines run without a break. Therefore, they can develop faults that are difficult to detect. The faults can also reduce their productivity. With the introduction of artificial intelligence into CNC machining, CNC machines can self-diagnose faults, improve their productivity, and make high-quality manufactured parts.

Application Of CNC In Self-Driving Cars

Self-driving cars can sense the environment without human input. To achieve this, car electrical and mechanical components must have the highest surface and functional quality. CNC machining is important here due to its accuracy, precision, and tight tolerance when manufacturing such components.

Conclusion

CNC automotive machining is applicable for prototyping and manufacturing parts in the automotive industry due to the process’s accuracy, precision, and tight tolerance. Due to the high precision and quality of CNC car parts, there is a growing trend among automotive part manufacturers for a better application of the process.

As a rapid prototyping manufacturer, WayKen has years of experience in custom automotive parts and automotive prototyping. Our CNC machining services allow the creation of high-quality auto parts quickly and easily. We also offer a wide range of CNC plastic and metal materials, All these will guarantees that you’ll receive superior quality machined parts every time. Upload your CAD file and get your parts in days.

FAQs

What is the difference between 3D printing and CNC machining for the automotive industry?

On the one hand, CNC machining is a subtractive process, i.e., making the final products is achievable by removing parts of the workpiece. On the other hand, 3D printing is an additive manufacturing process that makes a final product by introducing successive layers of materials. Both processes are highly accurate. However, 3D printing allows for more customization. CNC machining is also compatible with a wide range of materials than the other.

What are the kinds of CNC machines used in the automotive industry?

There are different types of CNC machines applicable in the automotive industry, and the type used in the automotive industry depends on the complexity of the types. Simple parts can be machined using any CNC machine. However, it would be best if you had a sophisticated CNC machine for complex parts such as the gearboxes (either 4-axis or 5-axis). These machines can rotate along several axes and deliver more accurate cutting and tight tolerance, unlike the 2-axis and 3-axis machines.

Also, the type of machine depends on the process. Here, there are five types of CNC machines: CNC turning machines, CNC milling machines, CNC drilling machines, CNC laser machines, and CNC plasma cutting machines.

What are the materials used in automotive CNC machining?

CNC machining is compatible with many types of materials. The best ones for the process are termed highly machinable. The process is compatible with many automotive materials, including metals (e.g., aluminum, brass, stainless steel, alloy steel, etc.), plastics (such as ABS, PEEK, Polycarbonate, PTFE, nylon, etc.), wood, foam, and composite materials.

There are also lower machinable materials such as titanium (very hard) used in the automotive industry. While CNC machining is applicable here, they require special cutting tools.