Custom Manufacturing Services

Ensure precision and efficiency with WayKen’s CNC prototyping and custom machining services and meet your specifications for quality, timeliness, and affordability.

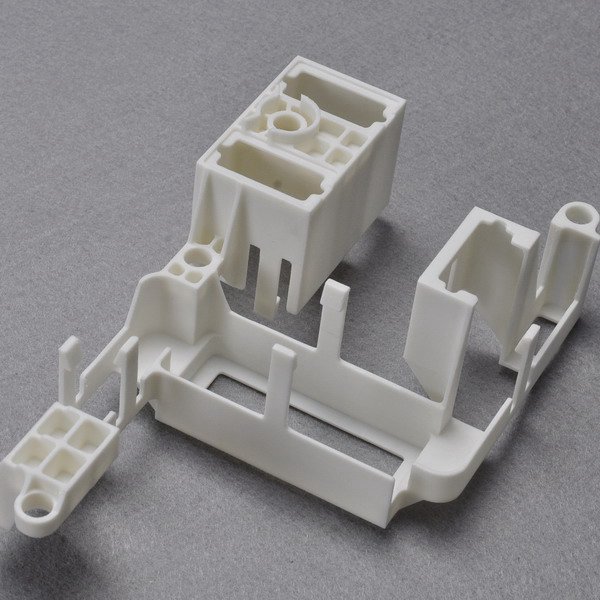

CNC prototyping service is the machining process to create plastic and metal prototypes, allowing your design team to closely simulate the final product’s appearance, function, and material properties, and test the suitability and manufacturability.

Custom machining is short-run or low-volume production to customer specific specifications and special needs, meeting precise quality, on-time delivery, as well as cost effectiveness and affordability.

Our Competitive Advantages in CNC Prototype Machining

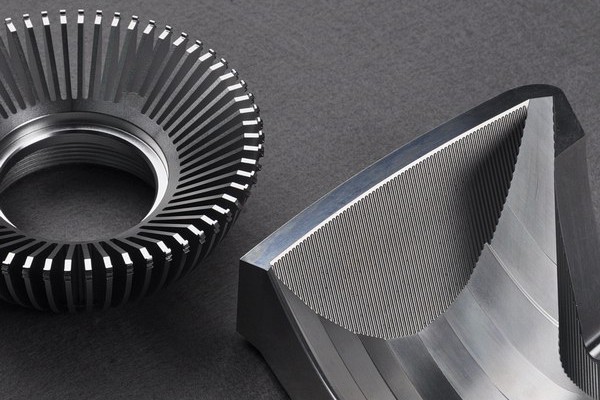

We are equipped with advanced CNC machine tools to provide fully integrated prototype machining capabilities. From 3-, 4- and 5-axis CNC milling and CNC turning, to auxiliary drilling, tapping, EDM, and wire EDM, all of these go beyond traditional setups and machining practices and ensure that we can perform complex machining tasks on time.

Our team works closely with customers to enable you to get a better manufacturing experience. Experienced engineers are available to provide technical support and offer manufacturing design assistance for your project, and a professional sales team always pays attention to your every detail needs and project progress and provides one-to-one follow-up services.

– Creating fully functional engineering prototypes that allow you to examine and test the form, fit, and function of components in rigorous working scenarios to help prove and refine your designs.

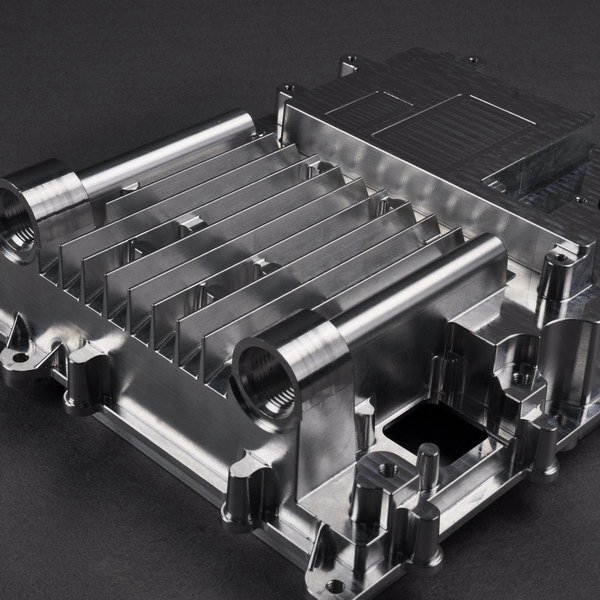

– Creating aluminum prototypes of complex designs with extended and integrated machining processes gives us the ability to handle a wide variety of aluminum machining projects with extremely tight tolerance control and excellent surface finishes.

– Creating optical prototypes of clear acrylics, high-speed cutting for complex-shaped free-form surfaces, and dense optical details using D0.1-D0.3 ultra-fine milling tools, providing micro-milling capability with excellent surface quality.

When Do You Need Custom CNC Machining Services?

Need 50 or 10,000 custom machined parts? We have the capability and experience to provide efficient custom machining services for your low-volume CNC machining projects at a reasonable price.

Custom CNC machining is ideal for special order requirements that require lower volume parts, or irregular delivery times and batches.

Turn to custom machining when parts with special requirements are not available from stock catalog suppliers.

In addition, custom machining is the reliable choice when high precision, high-quality parts, as well as special machining processes and accurate repeatability, are required.

Bridge production by custom low-volume CNC machining while you wait for production molds or dies to be made, allows you to get your product to market as early as possible.

Custom Machined Parts Gallery

From Prototyping to Production: WayKen Offers One-stop Solutions

WayKen provides high-quality custom CNC machining and prototyping services to customers worldwide. Bring your product from the design and prototyping stage through full production is our mission!

Machined Prototyping Solutions

Use of Real Materials

CNC prototype machining can use a variety of production-grade plastic and metal materials, which allows engineers to use the same (or similar) materials as the final part to make prototypes to test the product’s performance, function, and manufacturing cost.

Highly Accurate and Repeatable

CNC prototype machining allows a higher level of accuracy and precision to be achieved, typically tight tolerance of ±0.05mm or better. These are repeatable tolerances that can be achieved time and time again during low-volume production runs.

Quality and Consistently Finished Surfaces

Prototype machining provides a consistently smooth surface finish with a typical machined surface roughness of Ra 1.6μm and super-finish machined surfaces up to Ra 0.2μm.

Custom Machine Shop

Finding a custom machine shop that offers “made to order” can be a valuable addition to your supplier system.

WayKen has advanced machining equipment and flexible production methods, from simple milling or turning parts to complex and precision 5-axis CNC machining, from prototype plastic machining to accurate metal machining, we offer a well-rounded mix of advantages. Our custom machine shop maintains 24/7 operations for optimal efficiency, quality, and process control throughout the production process, from programming to machining to finishing.

Our in-house production capabilities combined with the ability to integrate external manufacturing resources allow us to have a quick turnaround to meet any of your custom machining needs. That’s why we can be competitive for your low-volume CNC machining projects.