The car gearbox is a critical mechanical component responsible for a car’s ability to move from one point to another. It does this by transmitting energy the engine generates to the car wheels and controls a car’s performance at different speeds.

A gearbox is an integral part of a car that you can modify for enhanced performance or suitability for other driving conditions. Hence, manufacturers must know about its components and various gearbox manufacturing techniques available, as discussed in this article.

What is a Car Gearbox?

A car gearbox or a car transmission box is a mechanical component consisting of gears, bearings, shafts, etc., located between the car’s engine and the wheel. It transmits power generated by the engine to the wheel, making it responsible for the car’s motion. Furthermore, it is responsible for controlling the car’s speed.

Parts of a Car Gearbox

A car gearbox comprises several components or parts, although this depends on the type of gearbox in the vehicle (automatic or manual). Nevertheless, here are the primary gearbox components in most vehicles.

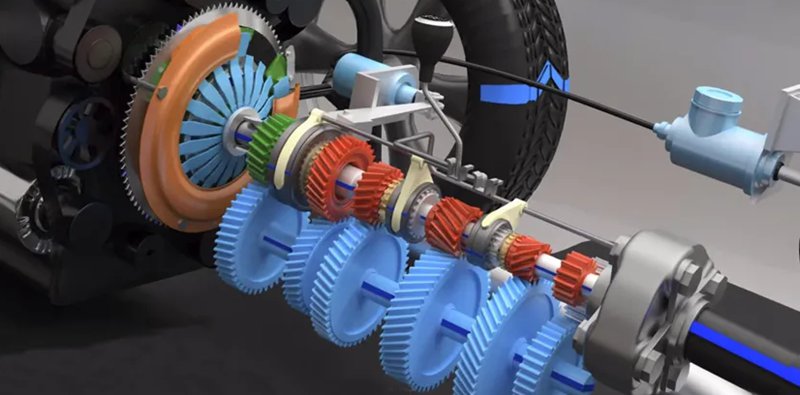

Gears

Gears

The gears in a car transmission box are metallic discs of different sizes with different ridges and number of teeth. They are in all car gearboxes, fixed on the shafts (except the main shaft), and can slide in either direction.

The transmission’s gear transmits power from one shaft to the next shaft, leading to the generation of torque depending on its size, number of teeth, and ridges. A large gear will generate high torque, leading to a lesser speed. On the other hand, a small gear will have a lesser torque, leading to a higher speed.

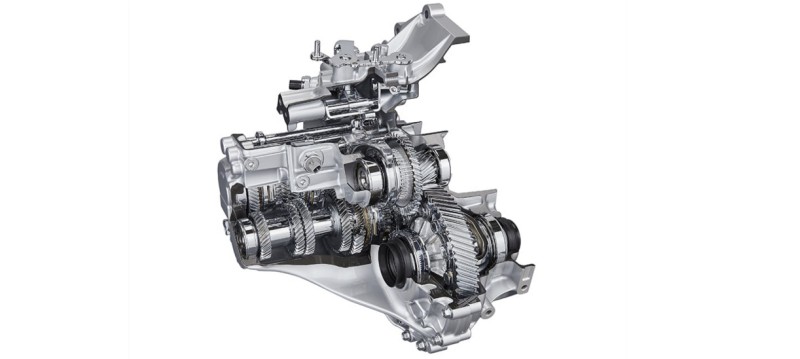

Shafts

Shafts

Shafts present in car gearboxes are the input shaft, countershafts, and main shafts. The input shaft, also called the driving and clutch shaft, is attached to the engine via the crankshaft and carries the power generated by the car engines

The countershaft connects directly with the clutch shaft and has a gear that connects with both the clutch shaft and main shaft. Furthermore, based on a direct connection with the shaft carrying the generated powers and the gear ratio, it can run at the engine’s speed or a lower speed.

Lastly, the main shaft or the primary shaft is connected to the universal shaft at one end and the countershaft at the other. It runs at the vehicle speed and a different speed from the countershaft.

Bearings

Bearings

This part of a gearbox functions in reducing friction while facilitating rotation. They are present on both the main and countershafts.

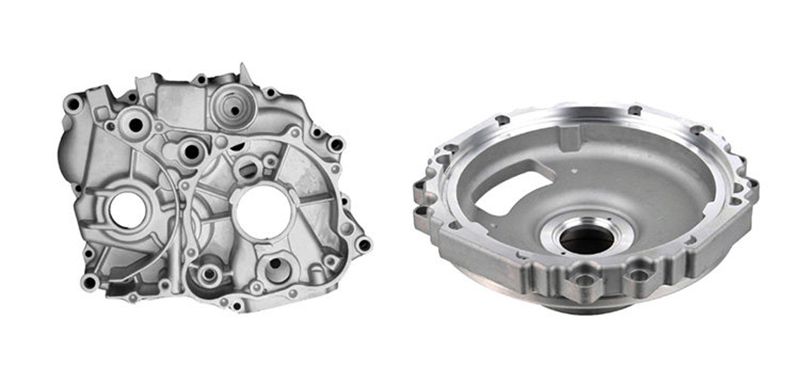

Housing

Housing

A car gearbox housing is a case that contains all the components of the car component. It is very strong and provides protection and support for the components.

How Does a Gearbox Work?

A car’s engine is responsible for the power required to move the car. However, the generated power must be sent through the car gearbox or transmission between the engine and the wheels.

Not passing the generated power through the gearbox will mean the wheel will run at a high speed. Hence, the location of the car transmission box in the vehicle setup and its functions helps tone down the engine’s power.

Manual Car

Manual Car

A gearbox in a manual car has seven gears, including first, second, third, fourth, fifth, sixth gear, and reverse. The driver pushes the clutch pedal to disconnect the gearbox. Afterward, he selects the gear using a lever connected to a series of selector rods attached to the top or side of the transmission.

The general notion is that using a lower gear will lead to a lower engine speed. This means the first gear has the highest torque and the lowest speed. The driver then releases the clutch and engages the accelerator to move the vehicle.

Automatic Car

In an automatic vehicle, there is no gear stick or clutch. The driver only needs to push the accelerator or brake pedal as expected. Unlike the manual vehicle gearbox, the automatic vehicle gearbox uses sensors to identify when the car needs to change gear.

To change the gear, the torque converter disengages the engine and the gearbox and creates pressure using transmission fluid. The pressure generated is then used to drive the sun, planetary, and ring gears, which meshes the gears together like the manual to achieve the required speed.

Types of Gearboxes You Need to Know

Car gearboxes come in different types but are classifiable under two main types: manual and automatic. Here is an overview of each type.

Manual Gearbox

A car with a manual gear also features a gear stick and a clutch. As a result, the driver has complete control over changing the gears and choosing the speed. Cars with a manual gearbox are cheaper than automatic gearboxes and have easier maintenance.

Advantages

Advantages

- Gives the driver total control over the choice of gears to use

- Low cost

- Low maintenance

Disadvantages

- Requires expertise

- It can be challenging and frustrating for new drivers

- It has a lower user experience

Automatic Gearbox

This type of car gearbox does not have a gear stick or clutch. Instead, it uses sensors and a torque converter, removing the driver’s control of the gear selection. Cars running with automatic gearboxes are costlier but more convenient to use.

Advantages

Advantages

- Better user experience

- Smooth gear changing

Disadvantages

- Costlier and more complex to maintain and repair

- Not suitable for off-road driving

Other Types of Automatic Gearboxes

The conventional automatic gearbox has a torque converter and other components that differentiate it from the manual gearbox. However, there are other types of automatic gearboxes based on how the gear is being changed. They include:

Automated Manual Transmission (AMT) Gearbox

AMT gearbox is a manual gearbox converted to an automatic gearbox. As a result, it retains the structure of the manual car gearbox but the features of the traditional automatic gearbox. Furthermore, due to the structure, it is less costly than an automatic gearbox. With an AMT gearbox, drivers do not need to engage the physical clutch during the gear-changing process, leaving the sensors to perform the task.

Torque Converter Gearbox

This type of gearbox uses a fluid to transfer the power generated by the engine to the transmission instead of a clutch. However, there is a decline in its use due to the high maintenance cost and fuel consumption.

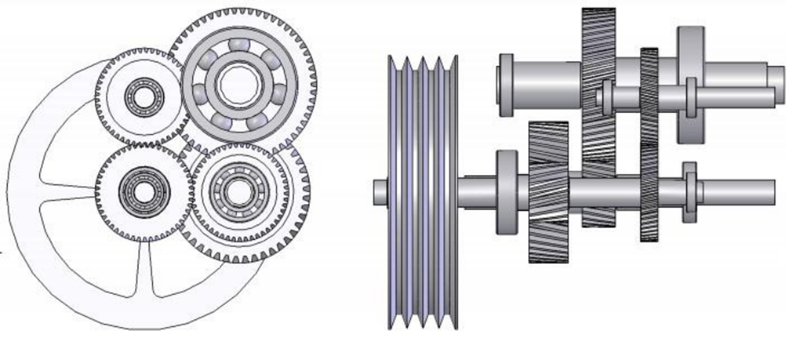

Continuously Variable Transmission (CVT)

This car gearbox is common in Japanese cars such as Nissan, Toyotas, and Hondas. It uses a pulley system where the belt changes in size (increase or decrease) to change the gear. It is. A very reliable automatic car gearbox with reduced fuel consumption

Dual Clutch Transmission (DCT)

The DCT has two clutches, which reduces gear shift lag during gear changing. As a result, it is quicker and smoother than the manual car gearboxes. On engaging a clutch, the other pre-selects the next gear. This fast transition makes them ideal in fast cars made by Audi, Volkswagen, Skoda, etc.

Manual vs. Automatic Gearbox: What’re the Differences?

Manual and automatic car gearboxes differ in structure and their effects on the driving experience. Below are a few distinctions between the two gearboxes.

Components

Components

The manual gearbox has several components that differentiate it from an automatic gearbox. Manual gearbox components include synchronizers, flywheel, selector fork, and stick shift, while the automatic gearbox components include the torque converter, output shaft, brake band, oil pump, planetary gear set, clutch packs, oil pan, and valve body

Driving Control

In a manual car gearbox, the driver has more control over changing gear using the gear stick and the clutch. On the other hand, an automatic gearbox removes the driver’s need to control the changing of gears

Fuel Efficiency

The efficiency of the automatic gearbox makes them better in terms of fuel efficiency due to the optimized engine performance

Learning Curve

Manual gearboxes have a steep learning curve compared to the automatic gearbox. Drivers can find it challenging and time-consuming to learn the coordination of the clutch and gear shifts.

Cost

Due to the lesser user experience and the components used in their manufacturing, manual gearboxes have a lower initial cost.

Car Gearbox Prototyping and Manufacturing Process

The choice of manufacturing process depends on factors including the production stage, materials involved, precision/accuracy, and production volume. The components and parts of a car gearbox are majorly metals and are compatible with the following gearbox manufacturing techniques.

CNC machining

CNC machining

CNC machining is a process for gearbox parts requiring high precision and tight tolerance, such as gears and shafts. It is a subtractive process that involves removing part of the workpiece to form the material using techniques such as milling and turning.

It is common in gearbox manufacturing for low-volume production. However, it is also suitable for prototyping gears during the early manufacturing phase for testing and validation.

Car gearbox businesses consider CNC machining for the following reasons:

- It can achieve high precision and tight tolerance;

- Suitable for different materials, including steel, aluminum, and brass;

- Doesn’t require much surface treatment.

Die Casting

Die Casting

Die casting is a more popular gearbox manufacturing process suitable for different materials. It involves injecting the molten metal material into a mold and allowing it to solidify and create the required parts. In addition, this process in gear manufacturing is more common for parts such as gears without teeth and large diameters.

Although accurate and precise, the parts are sometimes subjected to machining or other surface finish processes for improved appearance or functions.

Die casting is suitable for high-volume production and is popular among gearbox production due to the following:

- High dimensional accuracy;

- Compatible with different metal materials;

- It is a cost-effective production process.

3D Printing

3D printing is another gearbox prototyping process that involves creating a part by stacking the material up layers of layers to form a 3D object. Since parts of a gearbox are made mainly using metals, prototyping is very expensive and takes time.

The choice of 3D printing techniques for gearbox prototyping is due to the following:

- Flexible and fast design;

- Suitable for complex geometries;

Initial validation and testing.

Design Tips for a Car Transmission Box

Designing a car gearbox requires the utmost diligence and adherence to requirements for better operational efficiency. Here are some design tips that you can incorporate during gearbox transmission.

Get Main Parameters

Before you design a car gearbox, you should ensure that you have complete information on main parameters such as speed, torque, response time, and force. These main parameters are obtainable by considering the car’s purpose and condition of use. Furthermore, they are critical in car gearbox manufacturing as these parameters affect the design and the size of the gearbox.

Choose a Lightweight Material

For compactness and lightweight, to reduce the car weight and aid fuel efficiency. Common materials in making some parts of the car gearbox include aluminum and machined steel due to their strength and lightweight.

Operation Environment

Operation Environment

The operation environment of the car will determine other additions to the car gearbox. For example, in humid environments, you can take waterproofing measures such as sealing the gearbox and using special coatings to reduce the hindrance of the machine tools.

Gearbox Housing

The gearbox housing plays a critical role in the function of the mechanical component. In choosing the right design, you need to consider its layout, i.e., the placement of each gearbox component in the housing. Furthermore, you must consider a lubrication system to actualize proper oil flow, prevent leakages, and ensure seamless operation in extreme conditions.

Partner with WayKen for Car Part Manufacturing

Car manufacturing is a delicate business that professionals should undertake. At WayKen, we focus on quality-focused gearbox manufacturing and other custom automotive part services.

In addition, one of the key advantages of choosing WayKen is our emphasis on customization. We understand that different vehicles have unique requirements, and our manufacturing process in CNC machining, 3D printing, die casting, and injection molding, is flexible enough to meet various specifications.

Contact us today for your automotive projects, and let us turn your design into a car product.

Conclusion

A car gearbox is critical in power transmission from the engine to the wheel and controlling the car’s speed. Their modification can lead to better performance. Hence, businesses should know about the components and the corresponding manufacturing process.

FAQs

What material are gearboxes made of?

Gearboxes are mainly made using metals such as aluminum and machined steel, known for their strength, durability, and heat resistance.

What is the function of a gearbox?

A car gearbox transmits power generated by the engine to the wheel, allowing car motion. Furthermore, it is responsible for controlling the speed of the car and changing the direction

What is the basic construction of a gearbox?

A basic car gearbox has the following main components: gear housing, gears, shafts, and bearings. Each has its functions. For example, bearings are present on shafts, reducing friction, while gears help in the speed.