The automotive industry needs highly accurate automotive parts to adhere to its high safety standard which increases the wide use of precision machining techniques. Also, automotive precision machining techniques improve production efficiency and the production of high-quality parts.

These precision techniques are applicable in auto part prototyping and manufacturing. However, this is only effective after understanding each technique.

What is Precision Machining in the Automotive Industry?

What is Precision Machining in the Automotive Industry?

Precision automotive machining is a set of machining techniques used in the automotive industry. They have high accuracy, and precision, and can make auto parts with very tight tolerance. There are several technologies included in precision machining to create complex and highly accurate auto parts.

Key precision machining technologies like CNC machining, Swiss Machining, and Precision grinding ensure the production of precise auto parts. As a result, they are very important in the automotive industry, especially in making automotive parts that require assembling.

Advantages of Automotive Precision Machining

Precision machining in the automotive part manufacturing industry has many advantages centered on its precision. Automotive part manufacturers use them for the following benefits.

Production Speed

Precision automotive machining techniques, especially those integrated with CNC, are highly production-efficient. As a result, they are applicable in rapid prototyping and manufacturing of parts at micro or small scale. Furthermore, this production speed leads to their reduced lead time when compared to the conventional machining processes.

Automation

Most automotive precision machining techniques are automated. As a result, they are more efficient, streamlined, and accurate. Also, automation reduces operator involvement so that automotive manufacturers can stop worrying about human error.

Precision and Repeatability

Precision and Repeatability

From its name, automotive precision machining techniques are precise leading to a better prototyping or manufacturing process. In prototyping, a precise process will enable the detection of flaws in a part. In manufacturing, high precision will lead to consistency in a part with different batches.

Therefore, the automotive industry relies on these precision automotive machining techniques because they deal with a large volume of parts that require high tolerance.

Lean Strategies on Precision Auto Parts Manufacturing

Lean strategies can help OEMs that are using precision auto part manufacturing that need to improve their production efficiency, reduce waste, etc. Common strategies associated with the auto part industry include:

Lean strategies can help OEMs that are using precision auto part manufacturing that need to improve their production efficiency, reduce waste, etc. Common strategies associated with the auto part industry include:

- Value Stream Mapping: It is a process that auto part manufacturers can use to identify and map out every step in a precision machining process. As a result, steps that add no value to the process can be removed.

- 5S Methodology: The 5S methodology comprises Sort, Set in order, Shine, Standardize, and Sustain and they help precision automotive parts manufacturers to improve production efficiency and reduce waste. Furthermore, the methodology allows manufacturers to reduce the time spent looking for materials and tools for making automotive parts.

- Total productive maintenance (TPM): TPM is a program that ensures the maintenance of equipment thereby reducing equipment breakdowns. Implementing this in precision machining in the automotive industry will lead to improved overall equipment effectiveness (OEE).

- Implement Just-In-Time (JIT) Production: Implementing JIT production in precision machining in the automotive industry means that manufacturers will only make the parts when needed. Consequently, this will reduce inventory holding costs and the accumulation of obsolete parts.

- Poka-yoke: It is a Japanese term that means “mistake-proofing.” Implementing this lean strategy will help you prevent defects and mistakes during the machining process and eliminate possible errors. As a result, there is better product quality.

Common Precision Machining Processes for Car Components and Parts

There are some precision machining processes for car components and parts in the automotive industry.

CNC Machining

CNC machining is a set of subtractive techniques that make use of computer-controlled tools to remove part of a workpiece. There are several CNC machining techniques used in prototyping and manufacturing singly or in combination with others. Common CNC machining used in the automotive industry is milling and turning.

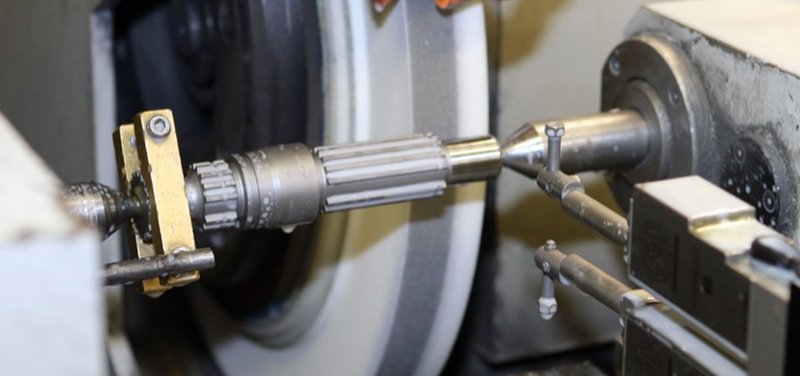

CNC Turning

CNC Turning

It is a technique that makes use of a CNC lathe machine with a mounted cutting tool/s that cuts away at a rotating workpiece to produce a final product. The CNC turning technique is applicable in making parts with external or internal cylindrical shapes like crankshafts and camshafts.

CNC Milling

CNC milling uses a rotating cutting tool mounted on a milling machine to remove part of a workpiece. It is applicable in prototyping or manufacturing complex precision automotive parts such as engine blocks, brackets, and cylinder heads.

Multi-axis Machining

Multi-axis machining, such as 5-axis machining, makes use of a cutting tool that can move in different directions. They are suitable for parts with complex designs and are more production-efficient. Consequently, many automotive machine shop makes use of them for auto parts with complex designs which are peculiar to the automotive industry and can make the entire machining process faster.

Swiss Machining Techniques

Swiss CNC machining makes use of a Swiss CNC machine with a peculiar design suitable for converting a metal stock into parts with complex designs and tight tolerances. It cuts the workpiece by turning it in a radial motion.

It is suitable for low-volume production of small precision auto parts like fuel injectors, transmission components like gears and shafts, and brake systems components.

Precision Grinding

Precision Grinding

Precision grinding is a form of grinding that focuses more on accuracy as it can grind small dimensions with a depth of 0.25 to 0.5mm. It involves an operator spinning a wheel with abrasive particles which removes part of the workpiece to make flat or parallel parts.

Materials Used in Precision Machining for Automotive Parts

Precision machining is compatible with a wide array of materials. Hence, auto part manufacturers can choose more based on the material’s performance, properties, and aesthetic value. Common materials compatible with the process and used in the automotive industry include:

Metal Alloys

Metal Alloys

Metals are important in making automotive parts hence their popularity in the industry. Some typical metals are:

Stainless Steel

Stainless steel is an alloy of iron and carbon that contains other elements with the most prominent being Chromium (10.5%). It is strong, durable, aesthetically pleasing, and corrosion-resistant. Stainless steel is applicable in the precision machining of automotive parts that should be corrosion-resistant such as car exhaust systems, door sills, and grilles.

Aluminum

Aluminum is a lightweight, corrosion-resistant, and strong material with good thermal conductivity. Common precision automotive parts made using the material are cylinder heads, engine blocks, wheels, and body panels.

Copper

Copper’s excellent heat and electricity conductivity makes it suitable for parts that need efficient thermal management. These include the car cooling systems like radiators and heat exchangers.

Magnesium

Magnesium is a light yet structural automotive material due to its high strength-to-weight ratio. It is suitable for precision automotive parts that should be light but strong thereby not contributing much to the overall vehicle weight. These include steering cases, transmission, etc.

Plastics

There is an increase in the use of plastics in making automotive parts due to their strength but lightweight. Some common plastic materials compatible with the machining process are:

POM (Polyoxymethylene)

POM is strong, stiff, and thermal resistant. As a result, it is widely applicable in making interior auto parts such as handles, knobs, and levers.

PA GF (Polyamide with Glass Fiber)

Reinforcing polyamide with glass will increase the material’s strength alongside other properties such as stiffness and thermal resistance. As a result, the PA GF is applicable in making exterior and interior precision automotive parts like mirror housing, trims, and wheel covers.

Ultem (PEI)

Ultem is a strong plastic material with high-temperature resistance and chemical resistance. It is applicable in making car precision parts like lighting components and electrical connectors.

PMMA (Acrylic)

PMMA or acrylic is a transparent, lightweight, and UV-resistant material suitable for automotive parts with optical functions. These include the car lens and light covers.

Polycarbonate

Polycarbonate is a strong plastic polymer that is transparent, heat-resistant, and impact-resistant. It is applicable in making automotive lighting components such as the headlight and tail light.

Which Automotive Parts Require Precision Machining?

Automotive precision machining is applicable in making the following components due to its accuracy and tight tolerances.

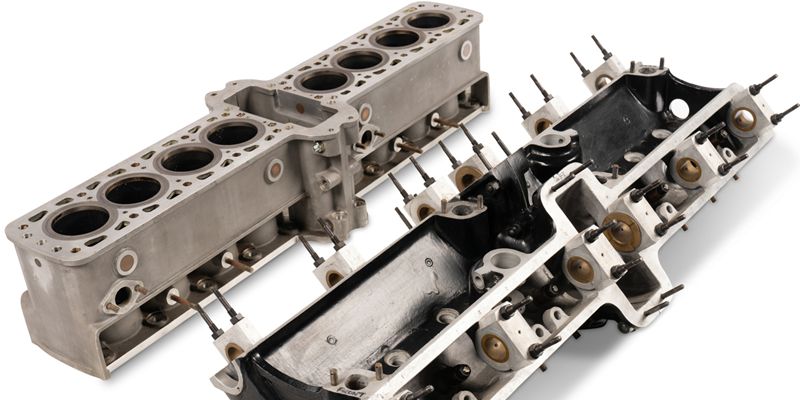

Cylinder Heads and Blocks

Cylinder Heads and Blocks

The cylinder head is an auto part located on the engine block alongside the cylinder and other components. It requires a precision machining process as its surface must be flat and the combustion chambers must be accurate for easier coolant and oil passage.

Crankshafts

The crankshaft is a vital engine component responsible for converting the engine’s linear motion to rotational motion. Crankshafts require precise machining techniques for their components such as the journals, fillets, and keyways to reduce vibration and enable a smooth rotation.

Gears

Gears

Gears are car components responsible for the transmission of power generated by the engine to the wheels. The gear should have accurate features such as tooth profiles, clearances, and surface finishes, leading to the use of a precision automotive machining process. Furthermore, these machining processes are sometimes after other manufacturing processes such as die casting for achieving tight tolerance or better surface finishing.

Chassis

The car chassis supports the car and houses car components like the suspension, steering, and brake systems. These parts require precision machining for accurate fit and alignment during assembling.

Engine Blocks

The engine block contains components such as the piston, and cylinders and relies on precision machining because its components such as the cylinder bores should be accurate, of a specific shape (perfectly round), and with a specific surface finish.

Future Trends in Precision Machining for Automotive Parts

Future trends in the use of precision machining for the automotive industry will see a rise in the reliance on multi-axis CNC machining due to its higher precision, reduced production cycle time, and reduced material wastage. Furthermore, CNC machines will use automatic tool changers that allow the use of processes like milling, drilling, boring, etc., at the same time on a machine.

Emerging technology will also allow embedding sensors in machines to monitor their operating conditions. This will make it possible to expand machine-to-machine synchronization and reduce manual efforts. There will also be an increase in the adoption of cloud-based operations for improved real-time connectivity, better machine-to-machine communication, and improved manufacturing capabilities.

Choose AutoProtoWay for your Custom Automotive Precision Machining

Precision machining is important in making many automotive parts due to its high accuracy and repeatability. However, it is well done by outsourcing to a reputable precision machining service provider.

AutoProtoWay offers custom machining services using advanced machining techniques and an expert team. From prototyping to production, we will support all stages of your automotive product development. Contact us today to start a cost-effective machining solution.

Conclusion

Automotive precision machining is applicable in making prototypes and real parts used in the automotive industry. These techniques are accurate, allowing easier adherence to the industry’s high safety standards and part assembling. Looking for a reliable precision machining service? Contact us today.

FAQs

What are the challenges of automotive precision machining?

The challenges with automotive precision machining are the high initial cost of investment, complex setup, and quality control to ensure that auto parts meet the required tolerances.

What are the tolerances used in automotive precision machining?

The tolerance used in automotive precision machining depends on the automotive part. Generally, precision auto parts have tight tolerance measured in thousandths of an inch. For example, the precision crankshaft bearing diameter may have a tight tolerance of about ± 0.005mm.