OEM or original equipment manufacturer is a term frequently used in the automotive and information technology industry. Initially, it meant a company manufacturing a product mainly for rebranding or reselling to another company. However, today, this term means a lot of different things.

So, what is OEM meaning? What does it mean to the automotive industry? Are there pros and cons of using OEM parts? How does OEM differ from Aftermarket? Here we discuss everything you need to know about OEM Auto Parts.

What is an Original Equipment Manufacturer(OEM)?

What is an Original Equipment Manufacturer(OEM)?

Traditionally, an original equipment manufacturer is a company whose goods are made up of parts or components in a product made by another manufacturer. This second manufacturer subsequently sells the product as finished items to users.

The second manufacturer here is known as VAR (value-added reseller) because of the value addition done to the original item. Also, there is a close relationship between the VAR and OEM. This is because the OEM usually gets design specifications from the VAR.

In other words, OEM focuses on business-to-business sales, while VAR focuses on the product’s public or end users.

What Does OEM Mean in Automotive?

What Does OEM Mean in Automotive?

So, what is OEM meaning in the automotive industry? The OEM automotive industry is one of the most basic examples of OEM. In the automotive industry, it means that the automotive manufacturer produced the parts, not a third party. The OEM and VAR is the auto manufacturer when it comes to this industry. This differs from OEM obtainable in other industries, where the OEM and VAR are often spate entities.

Here, the auto manufacturer makes original auto parts for their vehicles, quite different from parts obtainable in other vehicles. The next step involves assembling these OEM vehicle parts into a car and marketing them to auto dealers for onward transmission to individual customers.

OEM component types for automotive comprise the body, powertrain, chassis, and electrical and interior parts.

How Does OEM Work for Car Parts?

There are two major ways OEM works for car parts;

Direct OEM: The auto manufacturing company produces OEM parts for their cars. These parts also serve as replacement parts. Where a defect occurs, these manufacturers sell these parts to car dealers that sell to individual car owners. These parts are of better quality and are often high performing.

Third-Party OEM: This involves using OEM car parts manufactured by a third party. In this case, the car manufacturer outsources the manufacture of car components to specialized OEM manufacturers. The role of the car manufacturer is to assemble the manufactured components in a car for sale to car dealers. Also, individual car owners can source replacement parts for their cars from these OEMs.

Characteristics of an Original Equipment Manufacturer in the Automotive Industry

Original equipment manufacturers in the automotive industry have several characteristics. Here are the major characteristics.

Licensing

Licensing

The ability to sell licenses is the first characteristic of original equipment manufacturers. So, for value-added resellers to use OEM parts, they must first acquire the necessary licenses. Also, this license often comes with hardware and software products.

Incomplete Spare Parts

Another feature among OEM parts is their incompleteness. OEM leads to the production of parts, not the complete product. They are often components of the complete product, not stand-alone products. In other words, assembly with other parts is necessary to use OEM parts.

Pros and Cons of OEM Parts

OEM parts are parts designed by an OEM and used as a part or replacement for a product. However, these parts have their pros and cons. Here are the pros.

Pros of OEM Parts

Dependable Performance, Added Value, and Safety

OEM parts have an unrivaled quality, as they are often a replica of the original automotive parts. These parts have the same measurement specification, finishing, fitting, and material quality as the original, making them a like-for-like replacement.

Furthermore, OEM parts undergo quality and standards tests from the manufacturer, which often gives them a high consumer safety rating.

Easy-to-Use Parts

Due to the high level of precision during the production of OEM parts, they are often easy to use. They often replace vehicular parts seamlessly since manufacturers consider the vehicle’s make and model during production.

Manufacturer Warranty

As a testament to the quality of the OEM parts, they often come with a limited manufacturer warranty. This warranty lasts up to one year, offering buyers protection from part failure.

Life Span

OEM products have high quality, which guarantees their lifespan. Usually, because of made from the right materials and processes, these parts last longer than those produced by third-party manufacturers. Also, the supplier of these parts often provides an ideal estimated replacement period, which helps you plan better.

Maintains Vehicle Resale Value

Using OEM parts instead of Aftermarket parts helps maintain a car’s resale value. This is mainly because using OEM parts ensures a vehicle retains its quality and appearance.

Performance

With OEM parts, the performance of the vehicle decreases more slowly. The reason is that the OEM parts take into consideration a vehicle’s make and model, thereby ensuring optimal fit and performance.

Cons of OEM Parts

Costly

Compared to other replacement parts, OEM parts are often more expensive due to the quality of parts, service, and warranties involved.

Potential Waiting Time

Installing OEM parts is the easy part of the process, but the difficult part is finding them. Since the parts are often custom-made, dealers may not have them in stock, so they would have to order. With order comes a potential waiting time that can stretch a period.

Limited Suppliers

Since not all manufacturers can produce OEM parts, there is a limit on the number of available suppliers. This limit in suppliers influences both the availability of OEM parts and their cost.

Overselling Superior Quality

In recent years, some aftermarket manufacturers are beginning to close the gap in quality between them and OEMs. They have achieved this through reverse engineering of the original manufacturing process. So, while buying an OEM part at a high rate guarantees parts that fit better, there is often just a minute difference compared to aftermarket parts.

Difference Between OEM Auto Parts vs Aftermarket

Difference Between OEM Auto Parts vs Aftermarket

While most people prefer OEM auto parts and agree that the cost associated with getting them is a worthwhile investment, some others believe Aftermarket parts are ideal. It is important to note that there are a lot of differences between OEM auto parts and aftermarket parts.

Compatibility

OEM parts have a high quality, longer life span, and are more durable. Also, value addition for resale is possible with OEM parts, and the product has a manufacturer’s warranty. OEM parts are also highly compatible with the car because manufacturing takes into consideration vehicular make and model. However, OEM auto parts are expensive due to their quality and production processes.

Quality

Aftermarket products are parts made by third-party companies. These parts are quite similar to OEM parts, but they are of lower quality, do not have a warranty, and often require extensive modification.

Regulation

There is a distinct lack of heavy regulation for aftermarket products, affecting their safety standards. The reason is that these parts are usually not crash-tested, which often reduces their lifespan.

Cost and Availability

Aftermarket parts are cheaper than their OEM counterparts and often reduce the company’s expenses. Aftermarket parts are also more readily available than their OEM counterparts, and some even boast the same quality.

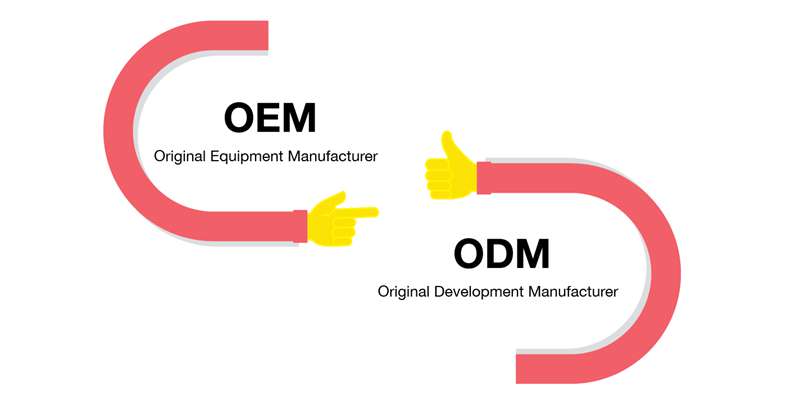

Original Equipment Manufacturer (OEM) vs. Original Design Manufacturer (ODM)

Original Equipment Manufacturer (OEM) vs. Original Design Manufacturer (ODM)

OEM companies manufacture products using the specification and designs provided by another company. In other words, the company demands the production of a part or component of a machine or vehicle. On receiving these parts, assembly and sales occur under the company’s trademark.

On the other hand, ODM companies make products using their specifications and design, with little room for modification. However, this type of manufacturing benefits suppliers as they spend less time on research, development, and design.

There are two categories of ODM manufacturing: private label and white label. Private label products are finished products sold to a specific retailer. White-label products are sold to different retailers, who rebrand and sell under their brand names.

How is an OEM Product Partnered and Resold?

Companies determine the best strategy to meet consumer needs before offering a product to the end users. They weigh several possibilities, including purchasing, producing, developing, and collaborating with another company to devise a solution.

An organization can minimize its manufacturing investment, lower production, and material costs, and obtain product design experience by partnering with OEMs.

Another crucial rationale for working with an OEM is a shorter product life cycle. The reason is that OEMs reduce the time to market with their specialization. It also allows businesses to create products employing best-in-class components while focusing on their core competencies.

OEMs don’t add anything to the product; some only brand it with their logo. Other OEMs don’t sell anything under their brand; they provide components to their partners. It is up to these partners to brand and market the products containing OEM parts.

WayKen: Your Custom Auto Part Manufacturer

WayKen: Your Custom Auto Part Manufacturer

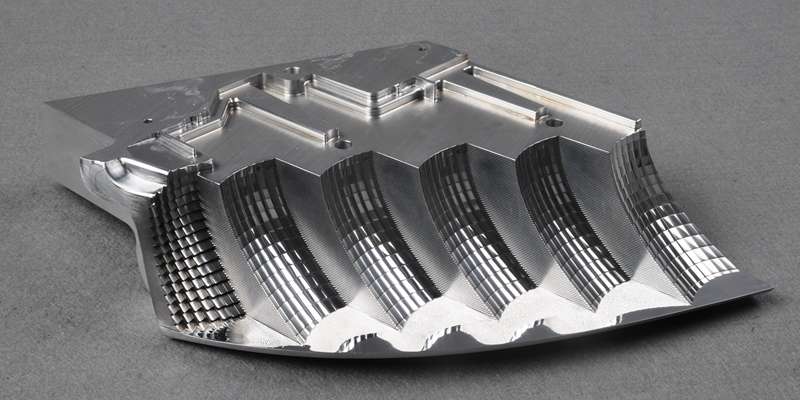

Are you looking to build OEM custom parts for automotive projects? Or do you have a concept car in mind? WayKen is a reliable rapid prototyping manufacturer, with years of experience manufacturing custom parts. Our custom prototyping and manufacturing services include CNC machining, 3D printing, vacuum casting, rapid tooling, etc.

We also boast a team of professional engineers and quality inspection specialists. Not sure of how to start to make your auto parts? Our professional team will help you to provide various auto parts machining solutions.

In addition, we offer competitive pricing, 30% lower than what is obtainable in America and Europe. If you are looking to produce custom auto parts, then WayKen is the right manufacturing company for you.

FAQs

Is OEM original or fake?

OEM stands for Original Equipment Manufacturer; as the name implies, it is original, not fake.

Is it worth paying for OEM parts?

OEM parts are often more expensive than those produced by third-party manufacturers like Aftermarket parts. However, their cost is acceptable because they are often a replica of the product part they are replacing.

Which is better, OE Or OEM parts?

Both the OE and OEM are similar in that they offer the same level of specification. However, they differ in price, as the OE is usually slightly more expensive.

Are OEMs from China?

Not all OEMs are from China, but China is one country with a high number of OEMs. The reason is that China offers manufacturers a higher quality part and a superior profit margin due to the low cost of production. Furthermore, the OEM parts produced in China undergo processing and labeling according to the specification of the foreign party involved.