On seeing a car, the first thing that attracts you is the car’s body. A visually appealing car attracts attention. However, its aesthetics goes beyond its body. The car’s interior also significantly influences the vehicle’s overall appeal.

Therefore, besides having an appealing structure consisting of the chassis, the frame, and the entire body, some car owners may choose to optimize their car by customizing the interior. This takes the car to another level, improving its aesthetics, functionality, and comfort.

This article explores the different custom car interior options, including interior manufacturing processes for these custom designs and material selections.

Types of Car Interior Components

Types of Car Interior Components

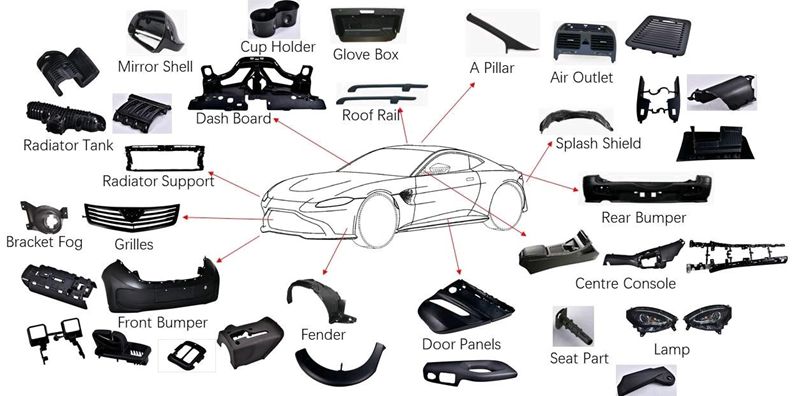

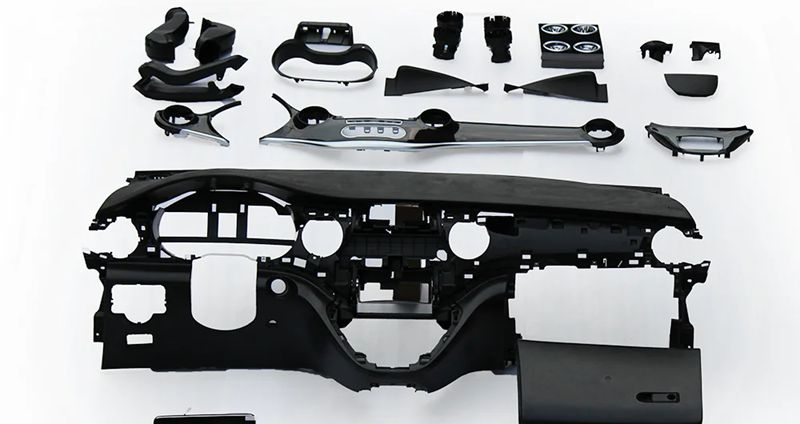

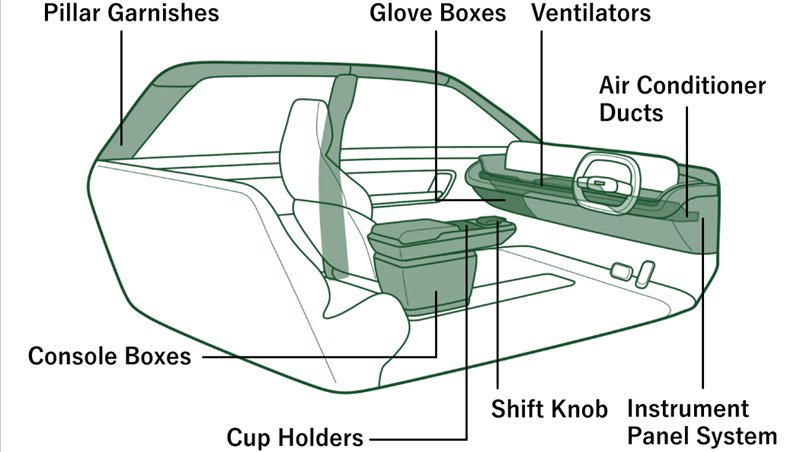

The car typically consists of its body, chassis, engine, and other structural parts. However, the interior components are also essential for the overall functioning of the vehicle. The car interior is responsible for comfort, especially when driving, and aspects of the car’s aesthetic appeal.

Therefore, some car owners may enhance these components to improve user experience and car performance. Below is a list of car interior parts that can benefit from customization.

- Dashboard panel

- Seats and upholstery

- Center console

- Door and trim panels

- Headliner and pillars

- Steering wheel

- Floor mats

- Shift knob and pedals

All these car interior components support different customization features, varying from modifying colors, patterns, textures, and shapes, among other finishes.

Materials Selection for Custom Car Interior Parts

The choice of material for customizing interior car parts determines the quality and aesthetics of these components. Therefore, whether metal or plastic, ensure the use of high-quality car interior materials to ensure durability and improved functionality.

Below, we will discuss some material options for designing interior car parts and the components used.

Plastics

Plastics

Plastics are common car interior material options for interior car components. These polymers are a good option for various internal car parts because of their cost-effectiveness, durability, machinability, and suitability for customization.

Below are typical plastics and their use for interior car components.

- Acrylonitrile Butadiene Styrene (ABS): components of car dashboards and interior door panels

- Polypropylene (PP): Interior door panels;

- Polycarbonate (PC): Internal lighting components and panels;

- Polyurethane: Arm and headrests, including other cushioned components;

- Polyethylene (PE): Interior car storage compartments and interior trim designs.

Composites

Using composites like carbon fibers in the automotive space is already a common practice because of its beneficial properties. They are known to possess a considerable strength-to-weight ratio and provide the car with a luxurious appeal. However, its use is often restricted to high-end vehicles because it is relatively expensive. These composites are used for interior car components like door panels, trim pieces, and seat backs.

Leather and Vinyl

Leather and synthetic materials like vinyl are the go-to options for upholstering car seats, gear shifts, and steering wheels. Besides promoting ergonomics, they add a luxurious feel to the car’s interior. Alcantara is another synthetic (suede-like) material used in making headliners and seat inserts. These synthetic car interior materials are easy to clean and boost the car’s appearance.

Metals

While there are fewer metallic components in the car interior, metals and alloys also find use in vehicle interior manufacturing. They are typically used for accent trims, brakes and accelerator pedals, shift knobs, and door panels. Common metals for these parts include lightweight aluminum and steel. However, titanium may be used in high-end vehicles’ interior components, such as in customizing shift levers.

Because magnesium is lightweight and relatively soft, manufacturers may use it in seat frames and brackets. These metals, upon appropriate surface finishing, contribute to the aesthetics of the vehicles. Also, they can withstand routine wear and tear conditions, such as the pedals.

Wood

Parts made of wood are rare in cars, though they may serve as luxury car interior elements. They could serve as custom design features like the car dashboards, steering and wheel inserts, and trims. They give the car interior a warm, natural appeal yet seem classic.

Custom Car Interior Design and Considerations

Custom Car Interior Design and Considerations

When customizing car interiors, the focus should suit specific preferences and focus on improving comfort, the car’s functionality, and style.

Below are significant considerations when customizing car interior components.

Ergonomics

Ergonomics should be the number one focus when customizing interior designs for cars. Besides aesthetics, the aim should be to promote seamless interaction between the driver and the vehicle’s control and other interfaces. A well-designed custom car interior should promote a comfortable driving experience, minimize distractions, and improve safety.

Aesthetics

While ergonomics should take center stage when customizing car interior components, you should also prioritize aesthetics. However, this goes beyond matching colors and material selection. It should also include the finishing choices, texture, and intricate details that help improve the overall car’s appearance.

Functionality

Besides ergonomics and aesthetics, car designers and OEM auto part manufacturers should ensure the car maintains premium functionality when customizing the internal features. In fact, you should work towards integrating the advanced tech to enhance the car’s features, especially the entertainment systems. Also, your custom design shouldn’t hamper vehicle components, such as the storage compartments.

Practicality

When customizing your car interiors, finding the perfect balance between functionality, aesthetics, and practicality is vital. As you enhance the car’s features, it should meet the driver’s needs and should support easy maintenance. This helps ensure sustainability, allowing you to enjoy the custom features for extended periods.

Manufacturing Processes for Custom Car Interior

There are various manufacturing processes that you can use to customize your car interior components. Each method presents unique capabilities and advantages for manufacturing your vehicle’s interior features.

Below is a brief overview of specific vehicle interior manufacturing processes, including the car parts you can use their services to customize.

CNC Machining

It involves using computer-controlled machines equipped with a series of cutting tools to remove components of a workpiece till the desired shape is achieved. CNC machining auto interior is exact and versatile, making it suitable for customizing car interior components.

The process is compatible with various material options, including metals, alloys, plastics, and composites, making it versatile for manufacturing various interior car components. This includes parts such as dashboard inserts, trim and door panels, pedals, center console components, steering wheel insert, air vent covers, and gear knobs.

Moreover, it allows the manufacturing of these components with high precision and repeatability, with fast production cycles. You can be assured that parts created with CNC machining will adhere to all your design specifications.

3D Printing

3D Printing

Unlike CNC machining, 3D printing is an additive manufacturing process that creates parts by building in layers till the final design is achieved. The process is also computer-controlled, ensuring high precision.

However, 3D printing is not the typical choice for creating the end product of custom car interior parts. Instead, it serves the purpose of prototyping, where manufacturers and OEMs use it to test a custom-made part’s suitability and functionality.

You see, 3D printing can create almost anything you can visualize, provided you have a CAD file of the intended fabrication. Therefore, the process is valuable for making parts for running tests and simulations to check if the custom car parts will fit their intended application.

Injection Molding

Injection molding is another additive manufacturing process. It involves first heating the material – often plastics – to molten form before injecting it into a mold cavity where it solidifies into the intended shape. The process is suitable for mass production and custom individualized car internal components such as door panels, storage compartments, trim pieces, etc.

Post-Finishing Techniques for Interior Car Parts

Post-Finishing Techniques for Interior Car Parts

One of the aims of custom parts fabrication is to improve aesthetics. Therefore, you should consider using one of the post-finishing operations we will discuss. These finishes help improve the component’s appearance, among other benefits, like increasing durability and functionality.

Painting

Painting refers to coating a workpiece by applying a liquid – paint or lacquer – as a form of finish. It helps to improve the appearance of the pat, as it supports different color variations and acts as a protective layer against corrosion. Painting as a finish suits various car interior parts, including accent pieces, trims, and dashboard components. It allows users to customize their car to a specific color scheme they prefer, creating a unique interior theme for your vehicle.

Polishing

Polishing as a surface finish involves using abrasive materials to smoothen and refine the surface of a material. Using this process on interior car parts enhances the appearance, creating a sleek and glossy finish. Polishing can help improve custom car interior parts like dashboard components, interior lighting parts, pedal and shift knobs, and decorative accents. The finish eliminates all visible blemishes and imperfections on the surface of these parts, enhancing their aesthetics.

Powder Coating

Powder coating is similar to painting. However, it uses a dry powder to coat the part’s surface, acting as a protective and decorative layer. Also, it allows the use of various colors yet still creates a more durable and resistant finish. Powder coating suits the customizing of seat frames, pedal assemblies, seat belt components, console brackets, and supports.

Anodizing

Anodizing is an electrochemical process that creates an anodic oxide that serves as a protective layer on the surface of a part. This finish is commonly used on metals like aluminum, improving its corrosion resistance and durability. Anodizing also supports color variations, improving the door handles, accent details, and trim components.

Benefits of Customizing Car Interior Parts Manufacturing

We have already briefly mentioned some benefits of customizing your car interior parts. Below, we will reiterate and bolster some of the points mentioned earlier, including other benefits.

Personalization

A significant benefit of customizing your car interiors is that it allows you to tailor some of these components to precisely what you want. For example, if you like cool, bright colors, you can customize your car interiors with appropriate surface finishing to suit your desires. Moreover, it gives car owners more sense of ownership and personalization, as the driving room aligns with their style and preference.

Luxury and Comfort

Luxury and Comfort

As we mentioned, a well-designed custom car interior must promote ergonomics. While improving aesthetics, among other benefits, it should be comfort-focused and have elements that depict luxury.

Increase Car Resale Value

Car owners looking to resell their car can proceed to make adjustments in the car or even go as far as customizing the interiors to increase the car’s resale value. Cars with enhanced internal features attract potential buyers and command higher value.

Technological Integration

Generally, customizing car parts often includes integrating advanced tech and features to enhance the car’s design. When you notice new tech, integrating it helps to keep your vehicle updated on the latest advancements, especially components of the infotainment and safety features.

AutoProtoWay: Your Expert Partner for Custom Automotive Interior Manufacturing

When planning to customize your car interiors, you need to partner with an expert service provider that helps to produce your car interior parts to meet your requirements. At AutoProtoWay, we offer one-stop services ranging from custom interior prototyping to low-volume parts manufacturing services, including CNC machining, 3D printing, sheet metal fabrication, injection molding, vacuum casting, and post-finishing. Just upload your CAD files and get a quote today!

Conclusion

Rebranding your car elevates it beyond a typical automatic device that helps ease transportation. Through customizing the vehicle, you personalize it to suit your taste and lifestyle, making it seem like a second home. This way, you make the car seem more like an extension of yourself.

Customizing your car interior helps promote comfort, luxury, performance, and overall driving experience. You must use the correct car interior materials and appropriate vehicle interior manufacturing methods to achieve this customization.

FAQs

What manufacturing method is best for customizing car interiors?

Different manufacturing processes suit customizing other car parts. For example, while 3D printing may create complex prototypes for personalized accessories, CNC machining suits trim panels and makes precision and accuracy in the dashboard components.

How does material selection influence custom car interior parts design?

The material you select determines the design’s quality and appearance. Therefore, the choice of material determines your custom design’s aesthetics, ergonomics, durability, and overall functionality.

Can 3D printing create custom car interior parts?

While 3D printing is often used for the prototyping stage of custom parts fabrication, the process is not limited to that phase. In some cases, designers and manufacturers may choose to 3D print the final product of an interior car part, especially those with complex geometries and intricate designs.