The car dashboard is an integral part of the vehicle’s interior component. They are crucial for enhancing the car’s appearance and performance. A typical dashboard consists of various symbols, signs, and car warning lights that give the driver information about the overall car’s functions.

This article provides detailed information about car dashboard symbols and their manufacturing process.

What is a Car Dashboard?

The car dashboard, sometimes simply called the dash or the vehicle’s instrument panel, serves as the control panel set of an automobile. It is usually placed in front of the driver. Along with the windshield, it is the divider between the driver and the car front. A typical car dashboard displays electronic signs, caution, indication symbols, etc.

Car Dashboard Signs

Car Dashboard Signs

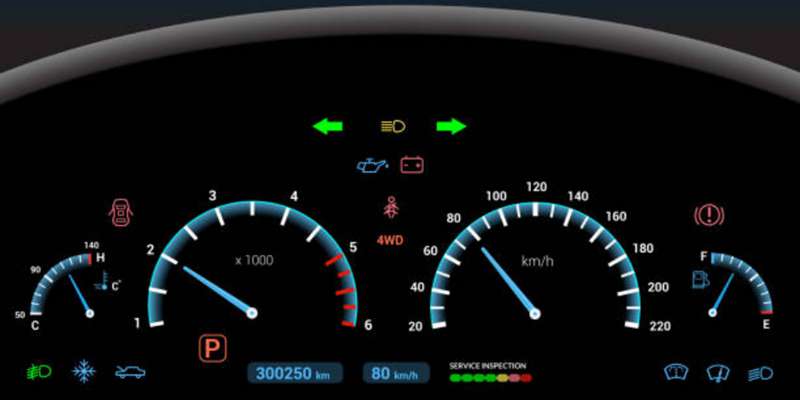

The type and brand of the car determine the dashboard functionalities. The features and sophistication of the dashboard and its signs may vary. However, regardless of the car type, all dashboards showcase an array of gauges, such as fuel level, speedometer turn indicators, etc.

More sophisticated ones may include features like climate control, entertainment system, engine coolant, temperature gauge, gear shift positions, dashboard warning lights, engine check lights, and other indications.

Different Meanings of the Car Dashboard Symbols

Every car dashboard illumination that appears on the dash has its meaning. However, not all symbols are a warning. Some are basic details about the vehicle’s features, such as when you turn your indicator or set your car on cruise control. Others may be mechanical warnings, such as decreased tire pressure, high engine temperature, or safety purposes, like blind-spot monitoring.

Often, the color designation of the car dashboard symbol indicates the interpretation. For example, blue or green lights denote the car engine system is functioning. In contrast, orange and yellow car warning lights suggest that your vehicle requires certain repairs or servicing. However, red lights are the most crucial ones, requiring immediate attention.

In fact, when driving and you suddenly notice a red check engine light, it may signal a severe mechanical issue such as an engine overheating. Therefore, if you continue to drive, your vehicle will eventually result in the engine stopping itself or lead to a more severe internal engine problem. However, some red flashing lights, such as seat belt reminders, are for caution and safety.

Types of Car Dashboard Symbols

Types of Car Dashboard Symbols

Below are some standard car dashboard symbols and their meanings.

- Oil pressure warning light: It means that there’s an issue with the oil pressure. It could mean there isn’t enough oil or the oil pump is faulty and not circulating enough oil.

- Tire pressure warning light: It suggests issues with tire inflation – either too high or too low.

- Engine temperature warning light: An indication that your engine is overheating. It’s usually a result of a car’s cooling system defect.

- Engine warning light: Also called the check engine light. It may illuminate for various reasons, such as a loose or an open gas cap. However, it may also come on for more severe issues like low oil pressure or other engine issues.

- Battery alert light: It indicates problems with the vehicle’s charging system, electrical problems like issues with the alternator, or a faulty battery cable.

- Low fuel indicator: It suggests low fuel in your vehicle, meaning you need to refuel.

- Seat belt reminder: This symbol is simply a reminder that either the driver or one of the passengers is not fastening their seat belts.

- Airbag indicator: It suggests issues with the car airbag system.

- Brake warning light: It turns on when there’s a defect with the car braking system.

- Door open indication. This dashboard signal appears when a door is not properly shut, or you forgot to close your trunk.

It is important to note variations in car dashboard symbols, especially when comparing cars of different makers, models, or years. For example, instead of the symbol denoting issues with that vehicle’s oil pressure, some dashboards just illuminate ‘OIL’. Therefore, when unsure what a dashboard light means, check your car owner’s manual.

In addition, when you kickstart your vehicle, most car symbols on the dashboard illuminate. You do not need to panic, as the car is just running a complete system check, after which everything normalizes.

Parts and Components of a Car Dashboard

The car dashboard consists of different parts and components: all interconnected to make a whole. They function and support each other. The specialized signs, symbols, and lights on the car dashboard give the driver information about the vehicle.

Typical dashboard components include the speedometer, engine coolant, temperature gauge, indicators, and other car warning lights and symbols. However, the car dashboard refers to virtually all the interior components in the car’s front, extending to the steering.

Below is a list of the different parts and components of a car dashboard

Below is a list of the different parts and components of a car dashboard

- Car indicator lights

- Car features and control center

- Head units

- Car drawers

- Ignition

- Indicator lever, etc.

Car Dashboard Manufacturing Process: Step by Step

There are several steps in manufacturing car parts and components. These processes are also applicable in the production of car dashboards. Below is a detailed layout of each step.

1. Car Dashboard Design and Development

Before starting any manufacturing process, you must develop a design to guide your creation. The design and development stage is crucial for any CNC prototyping, including the manufacturing of car dashboards or prototype cars.

Often, machinists draft a series of CAD models, then go with one that captures how they imagine the end product. During this stage, dimensioning is crucial, as an error in design measurements will affect the entire development. Other components include the different features the product will contain, design testing, and design for manufacturing which all determines the next line of action.

2. Material Selection for Car Dashboards

After having a design that mirrors what you intend to create, the next step is to decide on the ideal material that will suit your fabrication. Since we are discussing car dashboards, often made of plastic polymers, it is better to stick to engineering-grade plastics. They possess suitable mechanical and chemical properties, making them a good fit for this application.

Generally, the plastics used in car parts include

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Polyphenylene ether (PPE)

- Acrylonitrile butadiene styrene (ABS)

- Polycarbonate, etc.

These plastics are lightweight yet highly reliable, possessing considerable strength and resistance against shatter, abrasion, and various chemicals. Also, they can transmit and distribute light, making them an excellent material for displaying car dashboard symbols.

3. Car Dashboard Prototyping

After creating a design, including the necessary codes and programs required for the fabrication, the next step is to create design prototypes. The machinists input the programs into the numerical control panel of the CNC machine for prototyping. The prototype is a sample or look-alike of the intended fabrication – a 3D representation of the car dashboard.

Car manufacturers create prototypes to test the reliability and suitability of fabrication for the intended use, quality, etc. It may produce in large volumes for that car model when it meets all the functional requirements and design accuracy.

4. Car Dashboard Testing

As mentioned earlier, after the creation of dashboard prototypes, the next phase is testing. It involves checking and inspecting the quality of the fabrication, functionality, and if it suits the intended application.

Manufacturers may also expose the prototype to harsh conditions to simulate the external factors it’ll be predisposed to upon usage. This allows better testing of the durability and reliability of the prototype; those that fail the tests will be discarded. The manufacturers will have to modify the design to create a better product.

5. Injection Molding Process

When the prototype is ready, it’s time to move to volume production. Since dashboards are usually plastics, injection molding is suitable for such fabrication. Automotive injection molding is ideal for nearly every car part made of plastic, including car dashboards. The process involves heating plastic polymers into molten form before injecting them into aluminum molds, where they form the desired shape.

Plastic molding has vast applications and benefits for the automotive sector. Its suitability for mass production is one of the main reasons it’s a mainstay in this industry. Also, it is compatible with a wide range of plastic polymers and offers high reproducibility even when fabricating complex structures.

6. Car Dashboard Assembly

6. Car Dashboard Assembly

After creating each part, the next stage is to assemble the individual components – assembling about the end of any manufacturing stage. Parts are often manufactured singly, even though they are all components of a larger design. Assembling refers to fitting and organizing each design component to make the complete fabrication (dashboard).

7. Quality Control and Inspection

Quality control and inspection are pretty similar to testing. However, quality control is performed at every production stage. It involves validating every production process to ensure all standards adhere to the end product’s desirable quality.

Both quality control and inspection are needed to ensure the outcome of the manufacturing process meets or exceeds customers’ requirements and expectations. They involve examining, measuring, and inspecting the different events performed during fabrication that are critical to the outcome.

WayKen: Your Expert for Auto Prototyping and Custom Car Parts Manufacturing

WayKen: Your Expert for Auto Prototyping and Custom Car Parts Manufacturing

WayKen is an expert in manufacturing custom car parts. We can help you produce rare or customized car parts and automotive assemblies, including prototypes for your vehicle. Whether it’s a one-time fabrication or a long-term partnership, we are your best bet for your project. In addition, we offer premium services in CNC machining, 3D printing, injection molding, and other rapid prototyping technologies. Just upload your CAD files to get started with a new project!

Conclusion

The dashboard is an integral component of any automobile. They house a series of elements, symbols, signs, and lights on the dashboard that enable proper functioning and better control of the vehicle’s components. Manufacturing these components requires plastic injection molding services – a process suitable for fabricating almost any part made of plastic. Without car dashboards, driving automobiles will be less comfortable. Also, the overall appearance and functionalities of the vehicle may be affected.

FAQs

How are car dashboards manufactured?

Car dashboards are often manufactured using injection molding. The dried plastic of the selected polymer is cut in the injection molding machine, where they are heated and melted before being injected into the mold cavity, where they cool and solidify into the finished product.

What are the components of a car dashboard?

Car dashboards consist of different signs and car dashboard symbols that provide the driver with information about the vehicle. Also, it includes other components like the car drawer, ignition, indicator lever, etc.