Steel is one of the most reliable metals for auto parts manufacturing. Originally, the automotive sector utilized steel for cars because it offers the hardness, strength, and high strength-to-weight ratio that vehicle parts require. As a result, vehicle makers can design and assemble various vehicle components with the desired properties.

This article explores the benefits of steel and the types of steel vehicle makers used in the automotive industry.

Benefits of Steel in the Automotive Industry

Benefits of Steel in the Automotive Industry

Steel is a common raw material in various industries due to its flexibility and enormous benefits. This section discusses the various benefits of using steel for cars in the automotive industry:

1. Design Flexibility

Although steel is famous for its strength, it is quite flexible for different steel automotive design processes, irrespective of the machining process employed. Steel is ideal for making automotive steel components with outstanding corrosion resistance and aesthetic appearance. It is commonly known as the “universal building product.” Thus, many automotive steel products are in use, indicating the extent of steel’s design flexibility.

2. Recyclability

Sustainability is a major goal in the present age, so the ability to reuse steel material is another enormous benefit—some steel mills, such as the Electric Arc Furnace, use recycled material. Moreover, you can use and reuse steel without compromising any of its essential features in the process. Nowadays, most steel products comprise roughly 88% recycled steel. Using recycled scrap enables energy efficiency in the automotive industry.

3. High Strength

3. High Strength

Steel materials, especially high-carbon steel, offer a high strength-to-weight ratio and higher tensile strength. As a result, it can withstand more pressure without compromising its structural integrity. Also, this high-carbon steel is less vulnerable to fatigue failure making it the best option for parts exposed to frequent stress, such as drive shaft, engine crankshafts, and suspension components.

4. Durability and Quality

The durability of steel remains a primary reason why automotive manufacturers choose it. Using steel for cars offer long-term strength than plastic products, which are often susceptible to corrosion, combustion, and termites.

Moreover, processing and coating steel prevents it from rotting, splitting, cracking, or catching fire. It offers excellent structural integrity, long-term strength, and resistance to harsh weather conditions like gale-force winds, cyclones, and earthquakes.

5. Cost-Efficiency

Cost is often one of the primary considerations of manufacturers when partnering with a supplier or purchasing steel. Fortunately, steel provides the cost efficiency that your project needs. As such, it is not expensive considering its short- and long-term advantages. Also, you can quickly fabricate it, enabling faster and more cost-effective production.

Using steel for car parts saves time contributing to the material’s cost-effective nature. Above all, steel’s long-term durability improves insurance costs and reduces the possibility of component replacement in vehicles.

5 Types of Steel Used for Automotive Applications

Automobile industry manufacturers often utilize steel types for preferred features in different automotive parts. Here are the typical steel types used in the automotive industry.

Stainless Steel

Stainless Steel

A steel raw material only possesses the “stainless” designation if its elements include 10.5% chromium, 1% carbon, and other alloying elements. One of the extraordinary properties of stainless steel is its high resistance to corrosive compounds. Its shining and light-bodied design is often likened to functionality and durability in various industries, including automotive.

Moreover, stainless steel is ideal for crafting various steel car parts. Consequently, most cars contain about 15 – 20 kilograms of stainless steel within their exhaust channels. Manufacturers often use stainless steel for crafting fuel-combustion engines because stainless steel can withstand high temperatures.

Advanced High-strength Steel

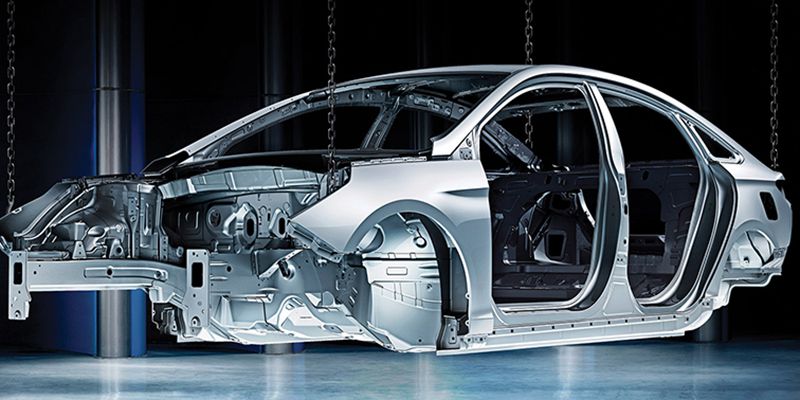

Advanced High-strength Steel (AHSS) is widely used in vehicle production. This sophisticated material is a product of modern steel innovations. Manufacturers often process the AHSS steel with unique chemical elements using cold rolling and alloying methods.

This modern generation steel offers a strength of about 2,000 Mpa and high durability. Being a lightweight material, it is well-available for creating undercarriages, vehicle bodies, frames, bumpers, and car doors. The AHSS offers excellent ductility, toughness, and outstanding fatigue rating. What’s more, several automotive manufacturers are working on different engineering solutions to improve the cost, performance, and safety of the AHSS.

The AHSS are often categorized as twinning-induced plasticity (TWIP), transformation-induced plasticity (TRIP), ferritic-bainitic (FB), martensitic (MS), etc. The martensitic (MS) is perfect for enhancing the performance and safety of vehicles. At the same time, the transformation-induced plasticity (TRIP) is ideal for creating engine crash zones or areas needing high energy absorption.

High-carbon Steel

High-carbon Steel

High carbon steel contains high carbon and is usually subjected to quenching heat treatment for sustainability. Meanwhile, the traditional steel heat treatment technique requires dissolving the carbon content in heated iron while rapid cooling traps the carbon and modifies the steel structure.

However, unlike ordinary steel, high-carbon steel alloys have low ductility and are vulnerable to brittleness. This steel has high resistance to wear and tear, making it suitable for applications in tools and metal automotive fasteners.

Manufacturers and designers in the automotive industry often use high-carbon steel to make bushings, chassis, door panels, vehicle frames, etc. Other applications involving the combination of high-carbon steel with different steel grades provide excellent support to panels and beams. This is because it helps to meet crash requirements, safety, and design standards.

Low-carbon Steel

Low-carbon or mild steel is famous for its high ductility and formability. It costs less and contains low carbon varying from 0.5% to 0.3%. These low-carbon steels exhibit reduced tensile strength and poor yield points. However, you can find components made with low-carbon steel on the exterior and interior of vehicles.

This steel is suitable for producing smaller components such as control arms, brackets, suspension parts, etc. Additionally, it has decorative uses such as making fasteners, wheel rims, nuts, bolts, screws, etc. Automotive manufacturers use low-carbon steel to maintain the structure and stability of vehicles.

Galvanized Steel

Galvanized Steel

Automotive manufacturers often use galvanized steel for vehicles due to its affordability and vehicle-making compatibility. This steel is more effective than aluminum and costs less than stainless steel. Nowadays, galvanized steel is widely embraced as a standard material in vehicle-making.

Manufacturers develop motorcycles, cars, and trucks using about 80% of galvanized steel. Moreover, you can coat galvanized steel with zinc to ensure the function and longevity of the vehicle. As a result, vehicles made with this coated steel will require fewer repairs and maintenance.

Conclusion

This guide has discussed the benefits and different types of steel used in vehicle production. You can locate any of these steel types in different vehicle regions. Meanwhile, the high-carbon and advanced high-strength steel types exhibit the strength property that any car requires. At the same time, the stainless steel, low-carbon steel, and galvanized steel types provide adequate strength with fewer downsides.

If you need the help of manufacturing experts in choosing the suitable steel type for your custom auto parts. Here is WayKen. We are a reliable custom manufacturing partner providing a wide range of steel to choose from. Our engineers are ready to offer automotive prototyping and part manufacturing services for you. Contact us today, and let’s discuss your next project!

FAQs

Which steel is best for constructing vehicle panels?

Stainless steel is the best material for crafting vehicle parts such as interior trim pieces, panels, tubing, and brackets due to its high melting point.

What is the standard size of steel materials?

Generally, steel plates and sheets usually have widths of 36, 48, and 60 inches and lengths of 96,120, and 144 inches.

What are the benefits of using high-strength steel in vehicles?

Manufacturers often purposely use high-strength steel in a vehicle to reduce weight, improving fuel economy and emission.