The automotive industry is currently undergoing a period of change to meet new environmental requirements. Environment workers and NGOs have been criticizing the automotive industry for many years. It’s because road transports are responsible for 25% of the total Greenhouse gas emission. That’s why lightweight material is becoming extremely popular nowadays.

Lightweight materials for automotive applications can reduce car weight by a great deal. As a result, they just need to burn less fuel. For example, reducing the carb weight by 10% will make the car 6 to 10% more fuel efficient. So, you can understand the importance of lightweight car parts from this basic calculation. We will explore this in this article.

Lightweight Materials: An Overview

Lightweight Materials: An Overview

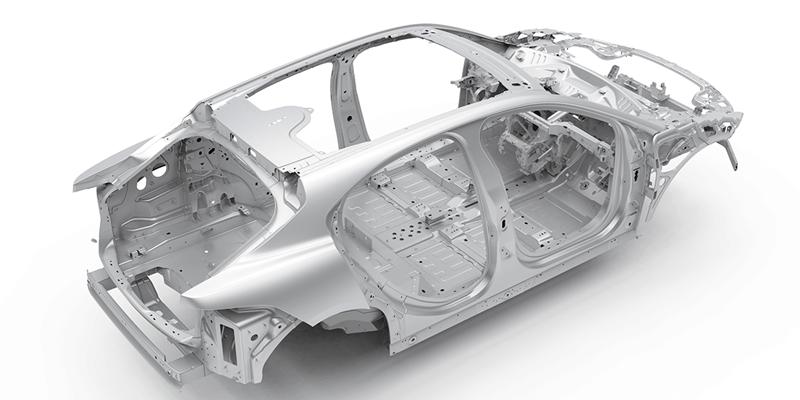

The automotive industry is always looking for ways to reduce the weight of vehicles. This is because lighter vehicles use less fuel and are therefore more efficient. One way to achieve this is by using lighter materials in the construction of vehicles.

One such material is aluminum. Aluminum car parts are much lighter than steel, which is the traditional material used in vehicle construction. As a result, using aluminum can lead to a significant reduction in vehicle weight.

Another lightweight material that is being used more and more in the automotive industry is carbon fiber. Carbon fiber is even lighter than aluminum, making it an ideal choice for weight reduction.

Manufacturers often use many other lightweight materials in a car. These include materials such as magnesium, titanium, and even composites made from carbon fiber and other materials.

The use of lightweight materials in the automotive industry is a major trend that is here to stay. We can expect to see even more innovative materials being used in the years to come. As fuel prices continue to rise, the need to reduce vehicle weight will become even more important.

The Benefits of Using Lightweight Materials in Automobiles

The Benefits of Using Lightweight Materials in Automobiles

There are many benefits to using lightweight metal and plastic materials in automobiles. From reducing environmental pollution to saving fuel costs for the customers, lightweight car parts are a blessing to the automobile industry. Here are some details:

1. Improves Fuel Efficiency

Lightweight materials improve the fuel economy by a great deal. If you use lightweight materials to manufacture different car parts, the car’s weight will reduce. As a result, riders will need less fuel to run the car.

Most modern-day vehicles use lightweight car parts to improve fuel efficiency. Less fuel is not only beneficial for the environment but also crucial for customers. Less fuel consumption means riders need to pay less for fuel. Research shows that a 10% reduction in weight can boost the fuel economy by 5 to 9%.

2. Improves Performance

Performance improvement is another crucial development in using lightweight materials for automotive applications. Performance is improved because the lighter the vehicle, the less energy is required to move it. This means that the engine can be smaller and more efficient. Additionally, the lighter the vehicle, the better the acceleration and handling. It’s easy to handle a lighter car than a heavy one.

3. Improved Safety

Another benefit of using lightweight materials in automobiles is that they can improve safety. This is because lighter cars have less mass, so they are less likely to cause serious damage in a collision. In addition, lighter cars are less likely to roll over.

It’s proven that lightweight materials are better at energy absorption. That helps the car to protect people inside the car by absorbing the impact of an accident.

4. Reduced Emissions

Another benefit of using lightweight materials in automobiles is that they can reduce emissions. This is because lighter cars produce less air pollution.

Aluminum – the Preferred Metal for Lightweight Car Parts

Aluminum – the Preferred Metal for Lightweight Car Parts

Aluminum has been the preferred metal for lightweight car parts for many years. Its popularity is due to its many benefits, including its low density, high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

-Aluminum’s low density makes it ideal for use in car parts where weight is a critical factor, such as suspension components and engine parts.

-Aluminum has a high strength-to-weight ratio means You can use aluminum to create both strong and lightweight parts.

-Aluminum is corrosion-resistant. As a result, aluminum parts will last longer, even in the most challenging environments.

-Ease of fabrication is another key advantage of aluminum. This metal can be easily formed, cut, and welded, making it ideal for creating complex parts.

-Aluminum is so widely used in the automotive industry. There is a large and well-developed infrastructure for sourcing, processing, and finishing this metal.

For all these reasons, aluminum is the preferred metal for many car parts. And as demand for lightweight, high-performance car parts continues to grow, aluminum will continue to be a key material in the automotive industry.

The Challenges of Working with Lightweight Materials

The Challenges of Working with Lightweight Materials

When it comes to working with materials in the automotive industry, there are always challenges. This is especially true when working with lightweight materials. Even though lightweight materials have many benefits, they can also be difficult to work with. Here are some of the challenges that can be faced when working with lightweight materials in the automotive industry:

Lightweight materials are often difficult to form into the required shapes. This can be a challenge when trying to create car parts that need to be precise.

Welding is a common process used in the automotive industry. However, it can be difficult to weld lightweight materials.

Painting a lightweight material can be difficult sometimes. It is easy to scratch or damage the paint on a lightweight material.

Lightweight materials can be difficult to work with in general. It is not easy to shape a lightweight material in the desired shape.

Lightweight Materials in Automotive Parts Applications

Lightweight Materials in Automotive Parts Applications

There are many lightweight materials manufacturers use for various automobile applications. Here are some of them:

Engine and Transmission: The most common are the engine and transmission. These parts are usually made of aluminum or magnesium. The engine is the most important part of a car. It is responsible for powering the car. The transmission is responsible for transferring power from the engine to the wheels.

Suspension, Brakes, and Wheels: Other parts that are made of lightweight materials are suspension, brakes, and wheels. The suspension helps to keep the car level and comfortable. The brakes are responsible for stopping the car. The wheels help the car to move.

Seats, Door Panels, Dashboard, and Console: There are many other parts of a car that are made of lightweight materials. These parts include the seats, door panels, dashboards, and console. The seats are usually made of leather or cloth. The door panels are usually made of plastic. The dashboards and consoles are usually made of metal.

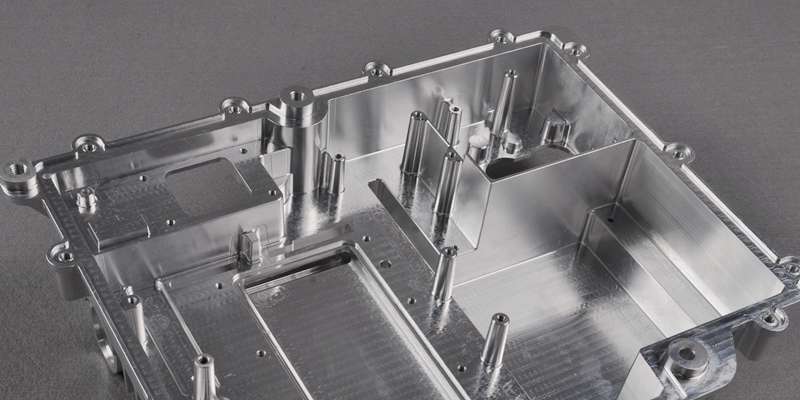

Get Your Custom Auto Parts at WayKen

So, we hope now you have learned more about lightweight materials in the automobile industry. But working with lightweight materials is not an easy thing to do. You will need deep knowledge, sophisticated machines, and long working experience to manufacture good quality lightweight parts for automotive applications.

WayKen has been in the industry for more than 20 years. Our engineering can handle various parts made of lightweight materials, including headlights, various product housings, automotive gears, etc. What’s more, we have a professional team to work with your order to ensure you can get the best services. Have any projects in mind? Get a free quote from us now!