The most vital part of a vehicle is its reciprocating engine. It is the heart of the vehicle because the vehicle does not work without the engine. However, the crankshaft is one of the most vital components of a reciprocating engine.

So, what is the crankshaft? What are the different types, components, and applications? We would also discuss how machinists make this crankshaft engine component and how it works in a vehicle. Do read on!

What is the Crankshaft?

What is the Crankshaft?

The crankshaft is a rotating shaft driven by a crank mechanism. It is a mechanical unit that facilitates the transformation of the linear movement of the piston into a rotating motion.

A crankshaft is an important part of an engine’s power transmission system. Located within the engine crankshaft block it works by using a connecting rod to convert the reciprocating motion of the pistons into a rotating one. This rotary motion generated by the crankshaft moves the flywheel, which consequently moves the vehicle wheels.

How Does Crankshaft Work?

A crankshaft contains several parts that work in tandem to make a vehicle move. It has crankpins and cranks connected to connecting rods and vibration dampers that help mitigate crank thrusts. Below is a detailed description of how the crankshaft works in a 4-stroke engine.

Downward Motion of Piston

In the first step, the engine piston moves from the top dead center to the bottom dead center in a downward motion. During this movement, the piston connected to the crankshaft through a connecting rod transfers its motion to it.

Motion Transformation

The next step involves transforming the piston’s linear motion into a rotary motion by the crankshaft. Furthermore, the crankshaft transfers this rotary motion to the camshaft after this transformation.

Compression

The camshaft receiving the rotary motion from the crankshaft facilitates the opening of the inlet valve. As a result, it allows the entry of air-fuel mixture into the engine combustion chamber. With the combustion chamber full, the piston moves from the bottom dead center to the top dead center in an upward motion, compressing the air-fuel mixture.

Also, as the piston moves upwards, the camshaft closes the exhaust and inlet values, completing the compression process. It also completes the first revolution of the crankshaft.

Ignition

The Ignition phase is the next phase after the completion of compression. The heat released at the onset of the ignition phase pressures the piston into a downward stroke, also known as a power stroke. As this downward motion progresses, the piston also transfers its linear motion to the connecting rod affixed to the crankshaft.

Flywheel Motion

The crank has two ends, with one end connected to the flywheel. Hence, as the crank receives the linear motion of the piston, it converts it into a rotary motion. Subsequently, the crank transfers this rotary motion to the flywheel, which stores the motion to facilitate vehicular wheel movement.

Exhaust Stroke

This stage ends in the discharge of exhaust gasses from the combustion chamber due to the piston’s downward motion. Here, the camshaft receives the downward motion of the piston, consequently opening the exhaust valve.

Types of Crankshafts

There are different types of crankshafts depending on the mode of formation. The different types of crankshaft include a fully built shaft, billet, cast, forged, single solid piece, welded piece, and semi-built shaft.

Let us examine these types of crankshafts in more detail.

Fully Built Shaft

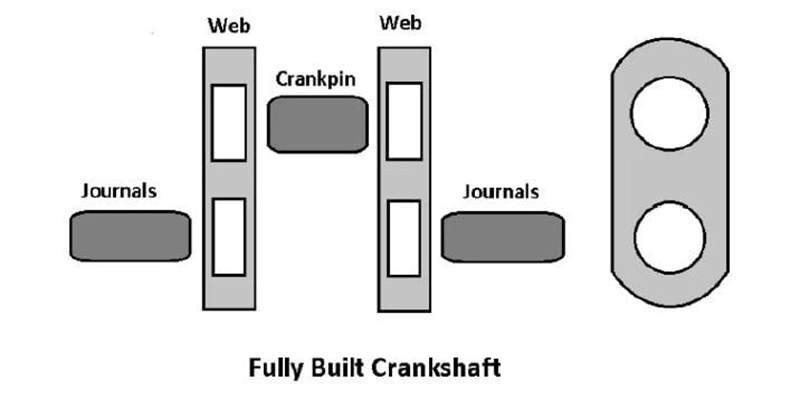

Fully Built Shaft

This type of crankshaft comes in individual parts. In other words, the crankpin, main journals, and crank web are apart. For this type, the individual crankshaft parts require assembling in a fully built shaft. The assembling involves machining and boring the journals and crankpin into the crank web.

After fabrication, shrink fitting of components ensures the crankshaft stays together. This type of crankshaft is often slightly smaller in diameter.

Welded Shaft

These are crankshafts made by assembling the main journals on both sides of the crankpin and web. After assembly, the next thing is to use the submerged arc welding process to weld these components together. Crank webs used in this type of crankshaft are often thinner, and the journals are usually stress-free.

These are crankshafts made by assembling the main journals on both sides of the crankpin and web. After assembly, the next thing is to use the submerged arc welding process to weld these components together. Crank webs used in this type of crankshaft are often thinner, and the journals are usually stress-free.

Forged Crankshaft

Often used in some 16-valve engines and high-stress ones, forged crankshafts are one of the strongest shafts. Made using a set of dies with a shape and size approximately that of the crank, this type of crankshaft is durable. Besides, it has better dimensional stability due to its ability to react to heat treatment.

Solid Single Piece Crankshaft

Made through either forging or casting, solid single-piece shafts have been used in both high-speed and low-speed engines. The crankshaft design makes it able to endure load incurred during cyclic tension and firing.

However, it is important to note that this type of crankshaft undergoes stress due to the torsional and axial vibration of the main bearings and misalignment.

Billet Crankshaft

Commonly made using steel, billet crankshafts are one of the best. Aside from steel, this crankshaft also contains other elements like molybdenum, aluminum, chromium, and nickel. Billet crankshafts have the shortest machining time and only require a minimum balance.

Cast Crankshaft

Made with iron fabricated through the casting process, this type of crankshaft is present in various petrol and diesel engines.

Cast crankshafts are quite popular among machinists and manufacturers because they are pocket friendly and machinable. Furthermore, their random and uniform metal grain structure allows them to withstand loads from every direction.

Semi-Built shaft

The first step in making this crankshaft is forging and shrink-fitting the crank webs to the general bearings. The next step involves providing the crankpins with a smooth surface finish through the machining process.

Semi-built crankshafts are lighter in weight when compared to fully-built crankshafts. They can withstand bending and high shear stresses, which gives them application in the engine of some high-speed vehicles.

Common Components of Crankshaft

Common Components of Crankshaft

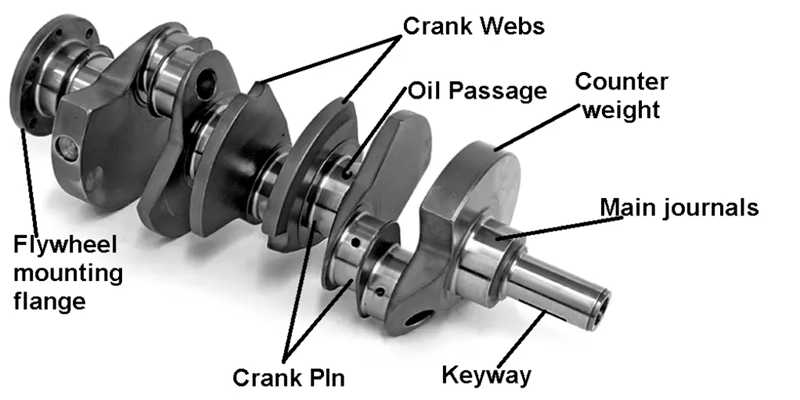

A crankshaft comes with several parts that work simultaneously to make it work. Without these parts, the crankshaft becomes just a piece of metal. The parts of the crankshaft include main journals, counterweights, flywheel mounting flange, thrust washers, crank pins, crank webs, oil passage, and seals. Below are the crankshaft parts and functions in detail.

1. Main Journals

The crankshaft journals provide a point of attachment to the engine block. They feature bearings that help hold the crankshaft in place while allowing the engine block to rotate around it. There are two types of bearings found in the main journals. They are journal bearings and plain bearings.

There are different types of main bearings, and they vary between engines. The bearing type found in an engine depends on its torque.

2. Counterweights

These are weights mounted on the crank web whose major role is applying the opposite force. In other words, counterweights provide much-needed stability and balance to the crankshaft.

Also, when the crankshaft rotates, a reaction could reduce the engine’s speed. However, counterweights help eliminate these reactions, helping the crankshaft achieve a high RPM.

3. Flywheel Mounting Flange

The Flywheel mounting flange is the point of attachment between the crankshaft and the flywheel. The flywheel flange part of the crankshaft is often larger than the other end, providing a face for mounting the flywheel.

4. Crank Pin

This part of the crankshaft facilitates a strong connection between the connecting rod and the crankshaft. Other names for this component are connecting rod journal and rod bearing journal. Crank pins always have a cylindrical surface. This surface ensures the pin flows with the rotating force found on the piston rod’s bigger end.

5. Crank Web

The crank web helps connect the main bearing journals to the crankshaft. This component of the crankshaft is of utmost importance.

6. Thrust Washers

Without thrust washers, the crankshaft would move vertically, in addition to its rotational motion. So, to prevent this, there are two or more thrust washers at strategic locations along the length of the crankshaft. There are also washers between the web’s surface and the crankshaft saddle to maintain specific clearance between the crank web and shaft.

Older engine types use separate thrust washers, but for newer ones, the washers are components of the main journal bearing.

7. Oil Seals

Due to the crankshaft extending beyond the crankcase on both ends, openings exist on these ends. One way to prevent oil from seeping out of the crankshaft is by using oil seals. There are two main oil seals in the crankshaft, one in front and the other at the rear. The front-end oil seals find their place behind the pulley and timing gear. This oil seal is accessible, making it easy to change.

On the other hand, the rear oil seal is between the rear main journals and the flywheel. This oil seal made from rubber usually features a molded lip held tightly within the crankshaft by the garter spring.

While this oil seal is inexpensive, accessing it is laborious as mechanics have to disassemble the clutch, transmission, and flywheel.

Factors Affecting Crankshaft Replacement Cost

Replacing a crankshaft is not an easy job. Several factors would influence the cost of replacement ranging from car model, cost of labor, and condition of cylinders. Let us examine these factors in more detail.

Labor Cost

Labor is one major factor that affects the cost of replacing a crankshaft. This is primarily due to the required work to bring out the shaft. To replace a crankshaft, it would be necessary to completely remove the engine from the vehicle and suspend it upright.

However, replacing a crankshaft is a time-intensive and laborious exercise, as the mechanic would have to return disassembled parts to their original position after replacing the crankshaft. Also note that the time required to change a crankshaft or undertake crankshaft repair ranges from serval hours to a few days, and with the time spent, the labor cost increases.

Engine Condition

The engine’s condition also determines how much you spend on replacing a crankshaft. Most times, when a crankshaft is bad, some other parts of the engine would require replacements. For instance, you might want to replace all bearings, bearing rods, seals connecting the camshaft, and transmission. Also, some mechanics might suggest replacing the cylinders or conducting a crankshaft test.

Replacing all these engine parts costs money, which would increase the total cost of replacing the crankshaft.

Cost of Crankshaft

There are hardly any aftermarket parts of the crankshaft in the market, so the replacement parts are mostly OEM. Quality OEM parts are usually expensive, increasing the cost of replacing the crankshaft. This is especially true for vehicles that are not very popular, luxury or performance vehicles. On the other hand, with very popular vehicles, aftermarket parts exist at a very cheap rate.

So the cost of the crankshaft depends on several factors including vehicle make and model, as well as the type of crankshaft needed; new, secondhand, or remanufactured.

How Crankshafts are Made?

How Crankshafts are Made?

There are two major methods for making crankshafts; casting and forging. These methods involve using different types of metal in auto parts manufacturing. The casting process involves making crankshafts from a metal like cast iron. This casting requires heating the metal until it becomes molten, then pouring it into a mold.

On the other hand, the forging process involves making a crankshaft using forged steel. The process entails heating a block of steel until it becomes red hot and then shaping it under extremely high pressure.

These processes are necessary to make crankshafts that can withstand the strain of rotation within an engine. Its parts, like the crankshaft journal, also undergo surface treatment like surface hardening for optimal performance.

Choose Wayken for Your Customized Car Parts

Crankshaft manufacturing is a process that requires a great number of skills and technical know-how to produce optimal quality. Not every machinist or machining brand can undertake this process satisfactorily, which is why you should choose Wayken for your custom car parts.

Who is WayKen? We are a professional auto parts manufacturing company with more than 20 years of experience in the automotive industry. We can undertake all manufacturing processes ranging from prototype to parts production and deliver excellent quality products that meet industry standards.

Choose Wayken today for optimal quality, experience, and quick lead time!

Conclusion

The crankshaft is an important part of an internal combustion engine. Without this component, engines would not function. It has different components, ranging from oil seals to main journals. These components work simultaneously to ensure the crankshaft performs optimally. We also discussed the different types of crankshafts and factors that affect the cost of replacing a crankshaft in this article.

FAQs

A crankshaft works on which mechanism?

A crankshaft works on a crank mechanism. This mechanism includes a series of crankpins and cranks connected to the engine through connecting rods.

Can a car run without a crankshaft?

Electric cars can run without a crankshaft as they rely on another mechanism for movement. However, internal combustion engine vehicles cannot function without a crankshaft.

What type of engine works without a crankshaft?

Engines that work without a crankshaft include turbines, rotary, and free-piston engines

How to extend the service life of the crankshaft?

One of the first ways to extend a crankshaft’s service life is by promptly changing the oil. Also, ensure no leakage of motor oil from under the glands. Perform checks on the cylinder head gasket to ensure coolant and fuel do not mix with the oil. Lastly, do not overheat the engine.