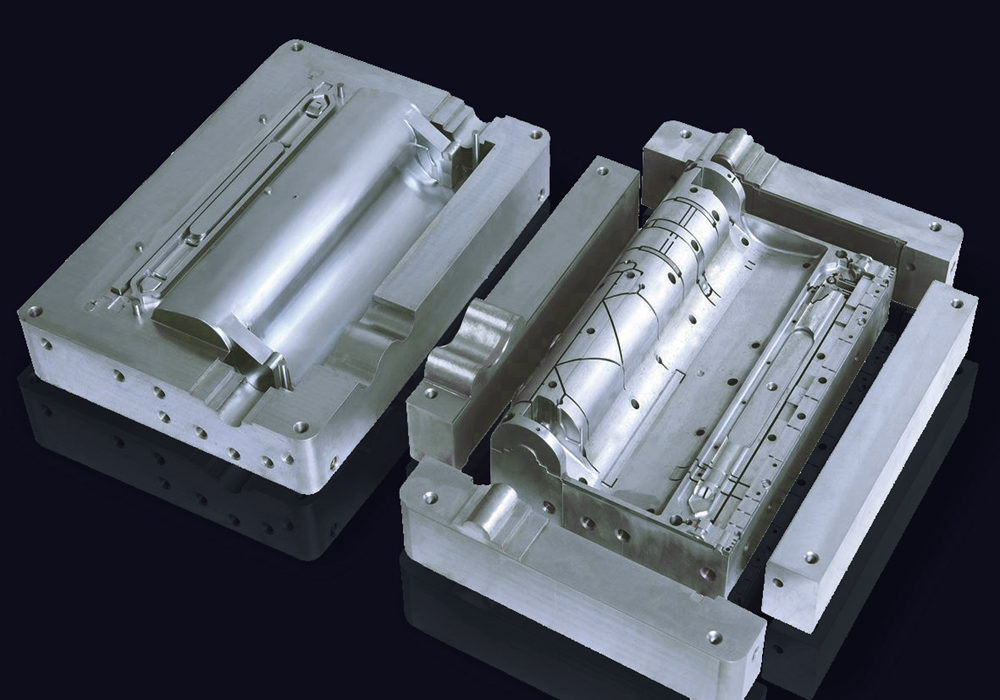

Rapid prototyping requires aluminum tooling the best mold material which is low cost and short lead time. Its rising popularity gave way for aluminum to obtain its current status in the injection molding industry. Let’s discuss everything you need to know about using aluminum for tooling.

Aluminum Molds for Rapid Prototyping

The main idea of using aluminum for tooling is to make cost-effective molds for low volume injection molding. Aluminum is easy to cut and has a rapid cooling rate, producing reduced cycle times and costs at the OEM level. Part production for rapid prototyping can begin almost immediately when the aluminum mold is ready. Rapid prototyping requires experts to fully maximize the potential of using aluminum for tooling. Douglas Bryce discussed how 7075 has a capacity to produce million parts. Manufactures only need to follow his recommendations to avoid choosing the wrong aluminum alloys and following good tooling practices.

Use Cases of Aluminum Tooling

There are certain ways to maximize the physical properties of aluminum as a mold for injection molding. With an aluminum injection mold tooling, you can potentially avoid shelling out big investments and waiting for months. The following processes emphasize how your company can benefit from using aluminum for rapid prototyping.

Rapid Prototyping

Rapid Prototyping

Aluminum is the optimum material to create rapid prototyping injection molds such as proof of concept prototyping. A prototype run doesn’t require tight tolerances and long tool life. But they need cost-effective production tooling and a short lead time. These requirements made aluminum the best candidate material for prototype tooling.

Low Volume Production

Aluminum is the optimum material for production quantities below 5,000 cycles. It enables the company to scale down their production capacity. You can invest a portion of regular costs to produce limited amounts of parts. We encourage you to use the run to failure method when using aluminum molds to help you avoid unnecessary maintenance fees.

Recommended Aluminum Grades for Tooling

Manufacturing companies don’t use any type of aluminum for tooling purposes. You must use an aluminum alloy to its correct usage because aluminum grades have different properties. So here we discuss the optimum alloy for injection molding tooling.

7075 (T651) Aircraft Grade Aluminum

Aircraft grade 7075 aluminum is the best material choice for aluminum injection mold tooling. It has a high strength and excellent machinability compared to other aluminum grades. It performs well for production injection molds and prototype tooling. A single tool can produce up to 2 million units with recommended machining techniques and correct usage.

6013 High Strength and Compressibility Aluminum

Aluminum grade 6013 provides advantages for bridge production. It has acceptable machinability, strength, corrosion resistance, and weldability. It can accommodate around several hundred thousand cycles.

2024 General Purpose Aluminum

General-purpose alloy 2024 aluminum is the entry-level material for injection mold tooling. It performs well for blow molding and structural foam. Its high copper content makes it slightly expensive but provides acceptable corrosion performance.

Advantages of Aluminum over Conventional Tooling

There are instances where aluminum provides better results than conventional tooling. It’s no doubt that conventional tooling can support high volume production. But aluminum has distinct advantages when used for rapid prototyping. Let’s elaborate the differences between steel and aluminum for injection molding tooling.

Price

Aluminum injection mold tooling has an edge for low-volume production. Using a conventional tooling to produce few parts requires you to invest 10 times the price. But when you use aluminum, you can produce a lower part cost with decreased quantities.

Keep in mind that aluminum has a better cost to weight ratio compared to steel. But aluminum has less density, providing more volume. That is why aluminum can provide more pieces of molds for the same price.

Lead Time

Aluminum is the optimum choice to attain low manufacturing speed for rapid prototyping. But keep in mind that there are recommended manufacturing techniques to get the best out of aluminum. So we encourage you to approach rapid tooling experts to enjoy the benefits of using aluminum for injection molding.

Rapid prototyping doesn’t require smooth finishes, tight tolerances, and complex designs. Aluminum being softer than steel makes it quicker to cut and form. Aluminum also doesn’t require heat treatment compared to conventional tooling which needs annealing. That is why milling aluminum injection molds using cnc machines only take up to 28 calendar days.

Cycle Time

Manufacturers cut the cycle time for rapid tooling using an aluminum mold. Aluminum has five times better thermal conductivity compared to conventional steel tooling. You can also reduce the need for water cooling because of the aluminum’s superior heat dissipation.

Longevity Tips for Aluminum Injection Mold Tooling

There are ways to prolong the life of aluminum injection mold tooling. It’s widely known that aluminum became famous for prototype tooling. But manufacturers found ways to prolong its lifespan by analyzing a few factors. That way you can use it as a bridge for production process.

- Aluminum is soft and has a short lifespan. We don’t recommend you to use it for high volume production.

- Aluminum is difficult to polish. You can only maximize it for high tolerance manufacturing such as end-use parts rather than mass production parts.

- Aluminum is harder to repair. Maximizing aluminum’s advantages is only applicable for proof of concept production and rapid prototyping.

Take Note: Aluminum for Injection Mold Tooling

We recommend you to have an overview of aluminum drawbacks before considering it for injection mold tooling.

- Aluminum is soft and has a short lifespan. We don’t recommend you to use it for high volume production.

- Aluminum is difficult to polish. You can only maximize it for high tolerance manufacturing such as end-use parts rather than mass production parts.

- Aluminum is harder to repair. Maximizing aluminum’s advantages is only applicable for proof of concept production and rapid prototyping.

Start Using Aluminum Tooling Today

Aluminum tooling is best for low volume manufacturing such as prototype creation or testing out the market. Making basic designs for future modifications is possible using aluminum as a tooling material. Start using aluminum for injection molding by contacting wayken rapid tooling experts today.