Rapid Bridge Tooling

Rapid Tooling, a Cost-Effective Solution

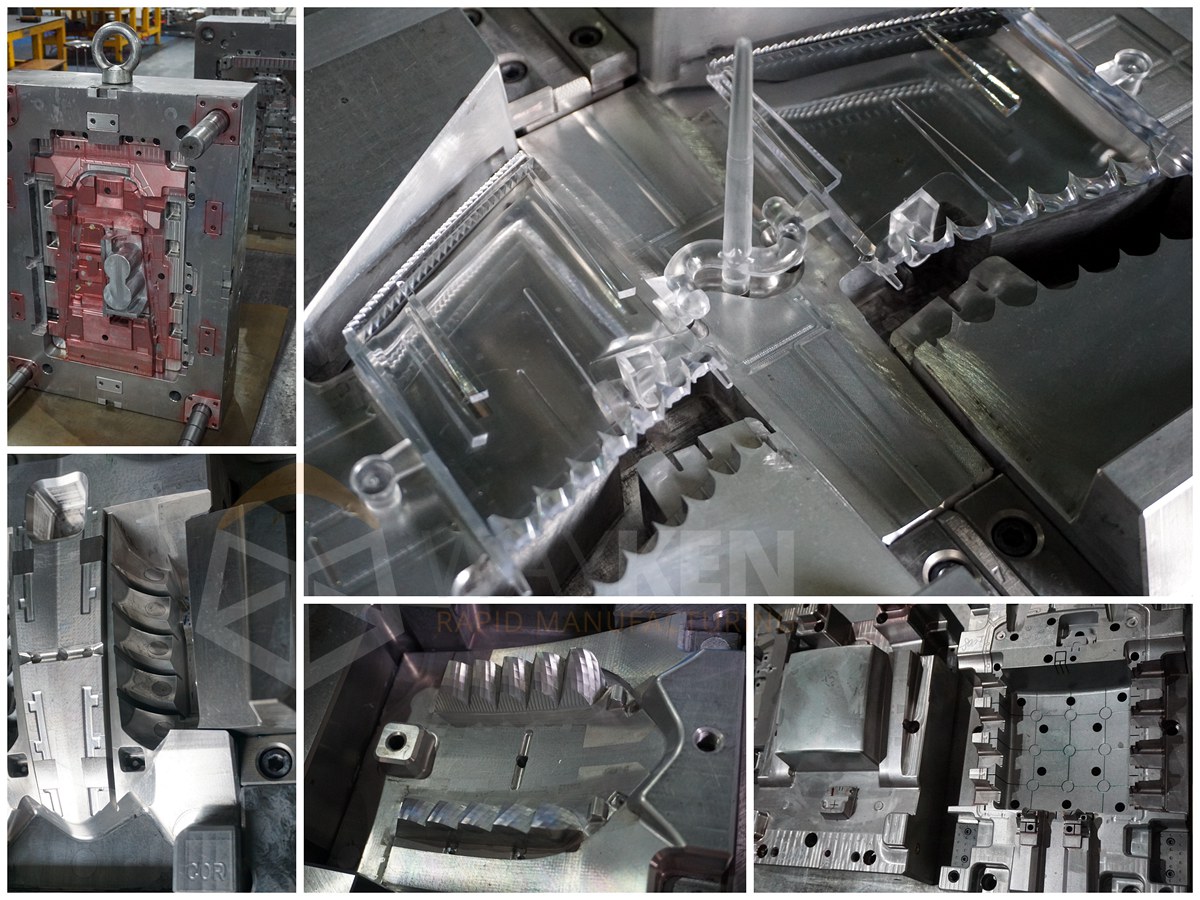

Rapid tooling, often called Bridge Tooling, Prototype Tooling or Soft Tooling, is a fast way to pre-produce hundreds or even thousands of plastic parts before mass production, for design optimization, functional testing, or pre-production verification, which can be a bridge between rapid prototyping and mass production.

Unlike traditional production tooling, rapid tooling has a more simplified mold structure and faster manufacturing speed that reduces the cost and saves project time, which is critical for successfully completing testing and moves into full production.

Rapid Aluminum Tooling, Receive Plastic Parts in 3 Weeks or Less.

Ready to build parts in a more cost- and time-efficient way? We combine traditional injection mold tooling methods with aluminum tooling, low-cost mold and fast turnaround will help you reduce manufacturing risk and can quickly produce qualified injection molded parts to production quality within 2-3 weeks.

We manufacture aluminum molds often using high-quality 7000 series aluminum alloys, which have excellent machinability, fast CNC feeds and speeds, and rough-milling 3-5 times faster than steel. In addition, aluminum can be machined by EDM, fine micro-milling, and polished to mirror finish or etched texture. So it allows you to produce a mold with the shortest possible lead time at the smallest customer expenditure.

Rapid Injection Molding, The Simplified Process is Not Simple

At Wayken, our experienced engineering team works with you to determine the best production process based on your customization goals and project expectations, providing cost-effective advice on design, materials, production processes, manufacturability, and more. Allows you to identify and correct design issues before mass production.

Our proven rapid tooling technology and high precision machining capabilities manufacture Class-A surfaces of light-guide and clear lens and provide tight tolerance control for functional test parts. We excel at combining technologies and performing cross-process operations.