The headlight lens cover of your vehicle goes beyond shielding the bulb or LED light source. It is a crucial component of your car’s lighting system and ensures even distribution and focusing of the produced light on the road. Without these lenses, you may find it difficult to drive at night.

What are Headlight Lens?

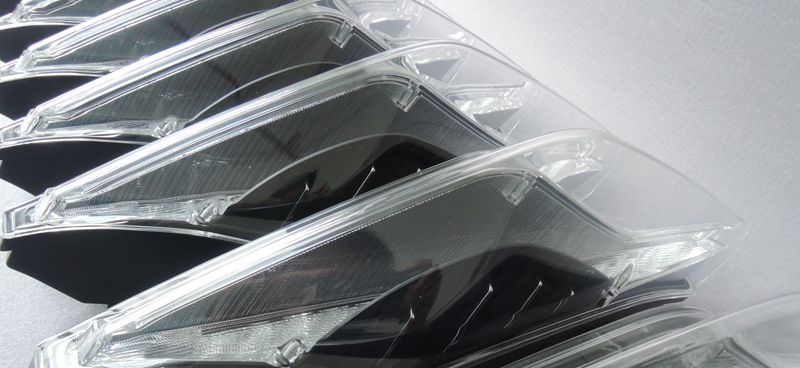

Headlight lenses are transparent protective covers or enclosures that shield the light source (bulbs), reflectors, and other internal features of an automotive headlight. They also protect delicate components of the vehicle’s lighting system as a barrier against dust, moisture, debris, etc.

In addition, they help ensure optimum performance and safety of the automotive lighting system. There’s room to customize these components for further aesthetics and achieve distinct automotive exterior lighting effects.

Benefits of Headlight Lens Covers

Benefits of Headlight Lens Covers

We have briefly highlighted some of the functions of headlight lens covers. However, below, we will give a more detailed overview of the advantages of these lens covers.

Protection

Headlight lens covers are a shield for the bulbs, wirings, reflectors, and other delicate components of the headlights. It protects the interior features against dust, stones, rain, and other environmental factors as a shield.

Enhanced Light Transmission

Well-designed car lens covers use premium materials like polycarbonate or acrylic, which possess outstanding light transmission properties, ensuring an improved light output. Therefore, the headlight lens cover will optimize the light produced by the light bulbs for more effective visibility, which is crucial, especially when driving at night or during harsh weather like rain or fog.

Durability

As the headlight lens shields its light source from environmental elements, it extends its lifespan. Also, the materials used for manufacturing headlight lens covers are usually highly durable, crash and impact-resistant.

Enhanced Aesthetics

These headlight lens covers allow you to customize your vehicle’s appearance. When designing a headlight lens for your car, you can choose a distinct color, style, and pattern to enhance your car’s appearance, giving it a unique, eye-catching style. You could even include a specific branding pattern or graphics as you customize the headlight lens.

Ease of Maintenance

Since the materials used in creating car lenses are usually crash and abrasion-resistant and can withstand harsh environmental elements, they tend to incur little to no maintenance costs. Some can even resist UV exposure’s clouding and yellowing effects, ensuring the lens cover maintains a clear aesthetic appearance for extended periods.

Customization

As the name suggests – custom headlight lens covers – are created for specific individual cars or models. Hence, you are assured of a custom and seamless fitting with no misalignment or gaps. As your custom headlights benefit from superior quality, they also enjoy a cover with a snug fit.

What Material is Used for Making Headlight Lens?

Various materials are suitable for creating headlight lenses, each with unique features influencing their suitability for manufacturing. Generally, many materials ideal for creating light pipes design will suit lenses for headlights.

However, we will focus on the following materials:

Polycarbonate

Polycarbonate is a popular headlight lens material because of its exceptional optical clarity and top-notch properties. Even though it’s lightweight plastic, it is highly durable and impact-resistant, allowing it to withstand harsh environmental conditions.

Using lightweight materials like polycarbonate contributes to improved fuel efficiency and vehicle performance. Still, it ensures optimum light distribution, ensuring a clear and bright light output. Therefore, it’s suitable for all kinds of vehicles, from compact aesthetical sports vehicles to large super-duty trucks.

PMMA (Acrylic)

PMMA (Acrylic)

Poly(methyl methacrylate), also known as acrylic, shares some similarities with polycarbonate, making it another popular choice for creating headlight lens parts. Its remarkable optical clarity allows precise and distortion-free light transmission for nighttime driving.

Also, it’s a lightweight material with good mechanical properties, such as UV and abrasion resistance, ensuring the production of durable lenses using these plastics. Moreover, the material suits different manufacturing processes and yields aesthetically appealing parts.

Composites

Composites are another suitable material for creating headlight lenses. They are usually a combo of polymers reinforced by fibers, which help to improve the mechanical properties. Like optically active plastics and polymers, composites for headlight manufacturing lenses also have appreciable optical clarity.

In addition, they are lightweight, cost-effective, strong, and highly durable. The combo of these properties makes them suitable for various applications, including headlight lens cover manufacturing. Also, they are highly flexible, allowing machinists the freedom to explore more sophisticated designs for customization.

Method for Manufacturing Headlight Lens

Manufacturing superior-quality, durable, aesthetically pleasing, and optically clear headlight lenses involve suitable manufacturing methods. Below, we will discuss some of the more common methods.

CNC Machining

CNC machining is a subtractive manufacturing method that involves using high-precision cutting tools, like CNC lathes, millers, etc., to reshape a material into the desired shape. In this case, the process involves reshaping materials like polycarbonate and acrylic to create headlight lenses.

Because the machining process is computerized, with the cutting tools controlled by computer codes and programs, it yields parts with high dimensional accuracy. Consequently, it is one of the most used processes for manufacturing in industries, including fabricating headlight plastic covers.

Moreover, it is highly efficient, especially for volume production, with impeccable versatility, as the process can create complex structures regardless of contours and other intricate features.

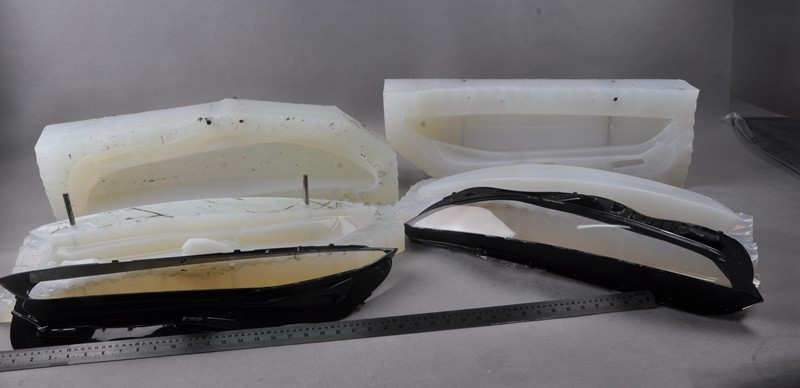

Vacuum Casting

Vacuum Casting

Vacuum casting is also known as silicone molding because it uses a silicone mold to create prototypes. It is one of the go-to processes for creating headlight lens covers. However, it is preferred for low-volume production, a feature that suits custom parts fabrication, as it allows for more flexible design changes with reduced manufacturing lead times.

The process is similar to injection molding, using liquid resin and polymers to create plastic and rubber parts. However, the manufacturing process uses silicone molds in a vacuum chamber, which helps ensure that the fabricated part is devoid of air bubbles.

Vapor Polishing

Unlike the first two manufacturing processes discussed, vapor polishing is more of a surface treatment and post-processing operation. It is a method for smoothing out plastics, resins, and various polymers at a microscopic level. The process involves using a volatile gas or vapor, such as Weldon 4 solvent gas, which is highly reactive, especially to polycarbonate.

Upon exposure of this vapor to the manufactured lens begins to soften and melt the plastic surface; upon resolidification, the resulting lens cover becomes optically clear and smooth. It is a typical surface finishing method for making headlight lenses, as it ensures the creation of lenses and covers with little to no blemishes and distortions, providing optical clarity and optimum light dispersion.

In addition, like typical polishing, vapor polishing imparts a glossy finish on the lenses, further enhancing the aesthetics and appearance of your headlight plastic cover.

Design Considerations and Practices to Get a High Optical Headlight Lens

Like any other typical fabrication process, there are things you need to put in place when fabricating a vehicle’s headlight lens.

Select an Optically Active Material

To ensure optimum light dispersion and visibility, you must use an optically active material, such as polycarbonate and PMMA must be used. Besides optical activity, these polymers possess excellent mechanical properties that make them ideal for making optical headlight lenses.

Lens Shape

The ideal shape of a headlight lens is convex (curved outward) for optimum distribution and practical focus of light. Ensure that your headlight lens is in this shape, as it promotes light dispersion as it is collected from the light source – bulb or LED before even projection, focusing the light on the road for improved visibility.

Surface Finishing

After manufacturing len parts with CNC machining, vacuum casting, or injection molding, it’s essential to engage in finishing operations to improve the properties of the car lens. Finishes such as vapor polishing help remove imperfections and blemishes and enhance the optical properties of the headlight lens for better activity.

Apply Optical Coating

Apply Optical Coating

Even after post-processing and surface finishing, you may still need to apply optical coatings to the finished lens. These coatings help to enhance the visual clarity of the manufactured headlight lens. It also improves light transmission and reduces possible reflection from the light source.

Uniform Thickness

It is advised that the cover of a headlight lens maintain the same thickness, as this allows for consistent and even light distribution with little to no distortions.

Applications of Headlight Lens

Headlight lenses are an integral component of your car’s lighting system, with the primary aim surrounding increased visibility. That said, we have already briefly mentioned several applications of custom headlight lenses.

Still, let’s list the applications of this automotive part.

- Provides adequate illumination;

- Enhancing the driving experience through improved nighttime visibility;

- Safeguards the bulbs and other intricate components of the vehicle’s headlights;

- Allows more seamless driving during harsh weather like snow, rain, and foggy conditions;

- Promotes safer driving through increased light dispersion, especially at dusk and dawn.

Maintenance and Replacement of Headlight Lens Covers

Proper maintenance of your headlight lens cover is critical for ensuring they remain in optimum condition for improved light dispersion and visibility. Generally, cleaning the headlight plastic cover with mild soap and water is enough care; this helps get rid of dirt and grime. However, you may also apply a protective coating against UV damage and hazing.

You can check for scratches during a routine inspection of your car parts. If you notice any, you can apply polish to make it shiny. Also, you should replace faulty or cloudy bulbs to ensure optimum visibility, which is crucial for safe driving, especially during harsh weather.

Regarding replacement, this applies when there are excess defects, such as when the headlight lens cover becomes overly scratched, broken, or cloudy. In any of these cases, you probably already experience reduced visibility, which puts you at risk of accidents due to poor lighting.

AutoProtoWay Expert Custom Your Automotive Headlight Lens

Creating a headlight lens is no small feat. It involves advanced manufacturing technologies like CNC machining and vacuum casting. Therefore, you should partner with an expert in manufacturing automotive headlight lenses, especially for your custom headlight lens machining.

We at AutoProtoWay are an expert in custom CNC machining, vacuum casting, injection molding, 3D printing, and other related technologies, including surface finishing that will benefit headlight lens manufacturing. We also can offer advice on how best to go about your projects and improve your design beyond what you imagined. Therefore, do not hesitate to contact us today for your automotive lighting projects.

Conclusion

Besides making driving at night more accessible and safer, headlight lenses can also help beautify and improve the overall aesthetics of your vehicle. Many car and motorcycle owners customize their headlight lenses for improved light dispersion and aesthetics.

FAQs

Are Headlight Lenses Concave or Convex?

Generally, headlight lenses are convex – bulging outward. Unlike concave lenses, which are diverging, convex lenses are converging. Therefore, light from the light source – bulb or LED- is collected together (converged), brought to focus, and dispersed on the road for better visibility.

Can Injection Molding Create a Headlight Lens?

Yes, injection molding is a suitable process for creating headlight lenses. In fact, vacuum casting is a type of injection molding, but the molding process occurs in a vacuum.

What Optical Properties Evaluate the Quality of a Headlight Lens?

Optical parameters for evaluating the quality of headlight lenses include the refractive index, chromaticity, and surface quality. An ideal headlight lens should have a uniform thickness be relatively smooth, shiny, and devoid of surface defects for optimum illumination. Other optical properties for evaluating these lenses include the beam pattern, luminous transmittance, and total luminous flux.