The world of manufacturing is growing fast, thanks to innovation. Every day, technology is evolving gifting manufacturers with amazing techniques like CNC machining. Not only that, but the advancement has also enabled CNC machining to flourish. And now, what seemed impossible in manufacturing is achievable with custom CNC parts.

To consumers, this is a blessing because parts get produced fast and are more affordable. The technique is efficient and capable of producing even the most complicated custom prototype. Whether you are talking about metals, plastic, or wood, is done with eased perfection.

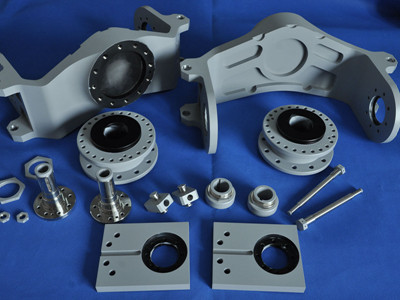

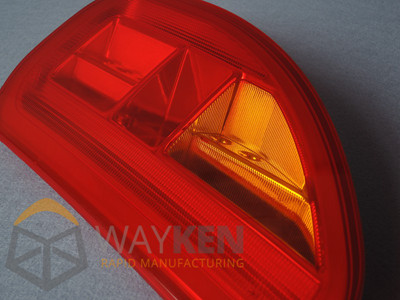

Manufacturing plants are opting for custom CNC machining instead of traditional machining. Furthermore, their application goes wide to industries like automotive, aviation, and aerospace. Especially, the demands on custom auto parts are pushing the fast development of custom CNC machining services.

Why Custom CNC Parts are Becoming Popular

First, let’s look at the making of Custom CNC parts. It’s also good to note that custom machined parts are products of CNC machining. The most popular manufacturing process in the world.

CNC machining works with predefined computer codes. These codes generated from CAM software are responsible for converting CAD drawings parts. It contains a series of special codes controlling the machining process. Above all, the computer codes are the ones that manipulate CNC machinings like lathe, grinder, and milling machine.

Manufacturers are concentrating more on low volume production instead of mass production. This shift in manufacturing has created room for custom prototypes to take center stage. Again, CNC parts play the role which guarantees flexibility and efficiency in the manufacturing system.

Another advantage of custom CNC parts is the ease of creation. Before, when crafting pieces from a complex surface, you needed to use a lot of additive manufacturing. The process was stressful and lacked accuracy and precision. Plus, it was expensive.

However, CNC machining has changed everything. The specialized computer-aided design has eased the manufacturing process. Moreover, it allows manufacturers to produce many custom parts with the machine, within the minimum time possible.

Material Used in Machining Custom Parts

CNC machining can produce parts from a variety of materials. But, many factors come to play when choosing. These include workability, corrosion resistance, price, strength, appearance, and weight.

Despite the versatility, you need to pick the suitable one. These depend on priorities; for example, titanium alloy is perfect for parts with exceptional mechanical properties. Other materials, such as Aluminium 6061 or Derlin, are better off with speed-oriented parts.

Aluminum is the most versatile material, affordable, and easy to use. The strength to weight ratio is excellent, plus it comes in sheer variety. It’s used in manufacturing custom CNC aluminum parts. Others are Stainless Steel and metals such as brass, copper, zinc, and titanium.

Equally, CNC machining uses plastic to produce parts. It’s suitable for prototyping parts in injection molding.

Methods Used to Produce Custom CNC Parts

When designing CNC tools, a lot depends on the application of the custom machined part. The operation of CNC machining varies in each action, but the integral components of computer numerical control software are consistent.

CNC Milling

A CNC milling machine is the most versatile one; it can mill flat surfaces or irregular surfaces. Also, they can drill, bore, cut gears, and create slots.

The CNC milling machine orients horizontally or vertically. Besides, a basic mill can do three-axis movements( X, Y, and Z), while an advanced model can use additional axes.

Computer programs manipulate the milling process. It comprises prompts that are in numbers and letter-based codes. These are the languages that guide pieces to move across the various processing stages.

Lathe Machine

Like CNC Mill, the lathe is versatile and essential. The machine rotates cylindrical against a part controlled by an individual. The device is a forerunner; it rotates on its axis as the cutting tool advances until it reaches the desired point.

CNC lathes are perfect for producing complex parts, like custom CNC aluminum. These parts are impossible to create in the manual version of the lathe machine. However, the control functions are directable with G-code, just like in CNC mills. But the difference is, CNC lathes run with two axes, the X AND Z.

CNC Drilling

The primary use of a drill machine is to enlarge holes on a workpiece. Drill bits allow waste, like chips to fall out from the workpiece. Moreover, there are several drill bits, and each has a specific application.

Examples of drill bits include spotting drills, used in producing shallow holes. There is the peck drill, for reducing chips from a workpiece. Then, there are screw machine drills, used for generating holes where there were none. And finally, the chucking reamers, which are perfect for enlarging, already produced holes.

Importance of Custom CNC Parts

Every reputable hardware has CNC machining tools for manufacturing custom machined parts. The reason for this simple, CNC machining is defining the future of manufacturers, and so are the CNC parts. Let’s see how.

- Custom CNC machining services enhance efficiency and production speed.

- Machined parts have high accuracy and are pre-programmed to make manufacture easier.

- CNC machine parts are not labor-intensive, but autoprocessing.

How We Can Support Your Custom Parts

CNC machining has opened avenues of possibilities, custom CNC parts are finding homes in every industry. These include automotive, construction, aerospace, agriculture, among others. Alternatively, the CNC machining tools have proved advantageous to every application. It’s also suitable and cost-effective for producing custom-designed parts.

As demonstrated above, custom CNC parts have grown popular. Not because they are custom made. The reason is, they come with the highest precision and accurate tolerance available.

AutoProtoWay.com is your custom machined parts machine shop to serve instant quotes and online ordering. Custom CNC machining offers every part in detail from your project draft.