A car is a sophisticated system of assembled parts working together for transportation. All parts of a car have specific functions, and as a car owner or prospective business owner that wants to venture into the car part manufacturing market, you should know about each car part.

Knowing the car parts names would help tackle problems due to faults or damages for owners and help businesses target the right manufacturing process. As a result, this article talked about the common types of car parts, their functions, and the manufacturing processes.

What Materials is the Car Made Of?

Car parts come from various materials. As a result, material selection is important as it helps in proper adherence to the usage of such parts and choosing the right manufacturing process. Here are the common materials used to make a car’s interior and exterior parts.

Metals

Metals are the most common material in automotive part manufacturing. They are strong, stable, durable, ductile, and good conductors of heat and electricity, amongst many other properties.

These properties make them the most suitable material for manufacturing vehicle parts. Several metals are used in automotive car parts, but the most common are steel, aluminum, and copper. The steel used in making bushings and bearings is common due to its cheapness, availability, and machinability.

Plastics

Plastics are popular in the automotive part manufacturing process due to their lightweight compared to metals. Generally, they are applicable in making components used in car interiors and contribute less than 15% of the total weight.

Despite their lightweight nature, plastics are durable and moldable into complex shapes. An example of such material is polypropylene, used in making the car bumper.

Composite Materials

Composite materials have high strength with excellent corrosion and wear resistance properties. As a result, they are slowly replacing metals in certain car parts in the automotive industry. Additionally, their lightweight increases the fuel efficiency of vehicles.

An example of composite material used in the automotive car part industry is carbon fiber, known for its impact resistance and used in making car tires.

Rubber

Rubber is highly applicable in part manufacturing due to its chemical and abrasion resistance. Furthermore, it can withstand extreme cold and hot weather conditions. Generally, rubber is applicable in making many car interiors and exterior parts, such as the bushing and the ducts.

Quick View: Main Car Parts Names

Although all car part names are important, some are present in every car. Below are the example of main vehicle part names which, without them, a vehicle cannot run

1. Engine

1. Engine

The engine is the brain of a car, and its state determines its performance of a car. It comprises the piston, crankshaft, cylinder head, manifold, oil pan, engine block, valves, and manifolds.

How does the Car Engine work?

For an engine to function, it begins pulling air and gas into the intake manifold. Afterward, with the help of fuel injectors, the intake manifold disperses the air-fuel mixture into the cylinders.

The cylinder’s internal combustion engine burns the fuel with the explosion exerting pressure that pushes the piston down, which supplies the power to move the wheels.

Manufacturing Processes

The engine experiences intense pressure while it functions. As a result, metals are the only suitable manufacturing materials. Aside from that, the right method is important in terms of the quality, precision, and accuracy of the part. The most common manufacturing process is casting (die casting and sand casting).

2. Chassis

2. Chassis

The chassis is the framework of a car that provides support. It holds the weight of other systems. Manufacturers use carbon steel for constructing chassis the most due to its strength, durability, and impact resistance. Other materials suitable for manufacturing chassis include aluminum and composite materials

Based on their shape, there are four main types of chassis:

- Ladder Frame Chassis

- Backbone Chassis

- Monocoque Chassis

- Tubular Chassis

The material used for the car body must be strong, durable, and have excellent impact and wear resistance properties. Steel and cast iron have all these qualities and are the material of choice.

Manufacturers use automotive metal forming technologies to produce car bodies using cold metals. These include bending, drawing, stamping, extrusion, and forging.

3. Transmission system

The vehicle’s transmission system works closely with the engine and is responsible for changing the gear. It sends power from the engine to the wheels to propel the car forward.

A transmission system can be manual or automatic and comprises components such as the clutch, gearbox, axle, and propeller shaft. Manufacturing transmission system parts such as clutch is challenging because it involves several techniques such as stamping, punching, bending, and heat treatment. Sometimes, it might require some finishing operations.

What Other Car Parts Name Do You Know?

The above are the main car part names. However, there are also others, including:

1. Steering system

1. Steering system

The steering system guides the car’s movement and comprises the column, steering wheel, steering shaft, pitman arm, and tie rods. These components are manufactured using materials such as aluminum or magnesium due to their strength, strong, and durability-though they are lightweight.

Although the steering wheel may appear simple, it may take years to design and produce. Hence, it would be best to have the right manufacturing and finishing process. Generally, the most common process for such parts is die casting.

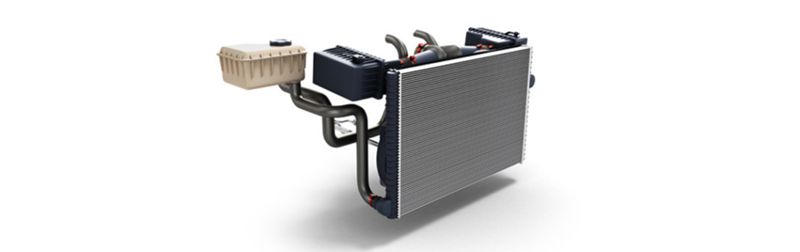

2. Cooling system

2. Cooling system

The cooling system cools the engine to maintain the engine at an optimal operating temperature. As a result, the engine can work efficiently without interruptions. It comprises a radiator, hoses, a coolant pump, a thermostat, and a cooling fan.

By continuously circulating coolant through channels in the engine block, they all work together to remove excess heat quickly from the engine.

The cooling system’s key component is the radiator, which uses paper-thin brass. Afterward, rollers bend this brass metal into flat tubes. The final process involves coating it with hot lead metal and chopping the tubing into the desired length using a cutter. For the plastic parts, injection molding is suitable. However, it would be best if you looked at the heat resistance and thermal expansion of the material.

3. Electrical System

3. Electrical System

The battery, alternator, and starter are the main components of a car’s electrical system. These components produce, store and deliver electric current to other systems. The basis of the electrical system is the battery. The starter receives power from the battery. This is replaced when the alternator supplies the battery with the energy it requires to run a car.

4. Braking system

4. Braking system

The braking system uses frictional force to slow down, stop and prevent movement when the vehicle is stationary. It comprises the master cylinder, brake drum, brake rotor, brake pad, brake caliper, and brake shoe.

5. Wheel and Tire

5. Wheel and Tire

The tire and wheel carry the vehicle’s and its passengers’ resulting load. Though they are used interchangeably, they are not the same. The wheel is a metal rim unto which the tires are fixed.

The wheel is made using either aluminum or steel. However, most wheels today come from cast aluminum alloys as they can withstand the heat generated during movement and impact due to the roads.

The tires comprise a combination of natural and synthetic rubber, chemical additives, and carbon black, which is responsible for their immense strength. Manufacturing tires involves using a tire-forming machine that wraps many layers of carefully prepared rubber around a metal drum.

6. Windshield and Windshield Wipers

The windshield is the glass in front of a vehicle that protects the passengers and car interiors. It comprises laminated glass made from two sheets of glass with a plastic layer in between.

The windshield is strong and requires extra effort to break them. It comes from many natural and synthetic rubbers, with polyisoprene being the most common. The manufacturing process involves squeezing the raw material into an extruder which forces it into the desired shape.

7. Fuel system

The components of a fuel system are a fuel tank, filter, pump, and carburetor. They store and deliver fuel to the cylinder chamber. Here, the fuel combines with compressed air and burns to produce energy.

Manufacturers use either plastics or steel to make fuel tanks. If weight is a deciding factor, plastics are ideal. The most common plastic used is high-density polyethylene. The manufacturing process involves melting and injecting the plastic into a suitable mold, giving the final shape.

8. Automotive Lighting System

8. Automotive Lighting System

The lighting system comprises headlights, interior lights, tail lights, etc. It functions in illumination and signaling during driving. Furthermore, the interior car parts have lighting for inside car illumination to provide adequate comfort and protection. Common manufacturing processes for car lights include injection molding, CNC machining, and vacuum casting.

WayKen’s Automotive Part Manufacturing Capabilities

Though many automotive parts have complex shapes and designs, they should have high accuracy and precision. As a result, manufacturing such car parts need special attention, and with WayKen, you have a third-party manufacturer that delivers quality parts at a competitive price and short lead time.

As an ISO-certified rapid prototyping company, we specialize in custom automotive parts manufacturing and automotive prototyping, especially automotive lighting prototyping.

At WayKen, our engineers are skilled in producing parts for your business for new vehicles and replacing parts for old ones. Not only do we shorten the time your product gets to market, but we also satisfy the rigorous standards and tight tolerances in the automotive sector.

Conclusion

While the car needs all parts for excellent performance, some are more important. It is important to check and replace old and worn-out parts routinely. Feel free to contact us if you have questions about car parts names and the manufacturing procedures.

FAQ

How many parts are in a car?

Each car system has a subsystem with its components. The exact number of parts depends on the type and model of the car. Typically, an average car has about 30,000 parts, including screw components.

What is the most important part of a car?

Though each type of car part is vital, the engine is the most important. Without it, the car cannot function at all. A car engine converts chemical energy to mechanical energy.

What current does a car run on?

Cars run using a direct current (DC). It may still function properly if you supply alternating current(AC) power to a car battery. However, the battery can completely shut down with no power left.