Moving from prototyping directly to mass production comes with risks and additional expenses. Low-volume manufacturing serves as a bridge tooling between both processes. Though manufacturers often overlook low-volume CNC machining, going through this process has many advantages.

Overall, low-volume machining minimizes the risks in manufacturing, shortens the time a product gets to market, and helps with easy modification of designs. To make the most benefits of low-volume CNC machining, it is important to understand how it works. There are tips one ought to follow to minimize time and budget when producing on a small scale using CNC machining.

What is Low Volume Production in CNC Machining?

What is Low Volume Production in CNC Machining?

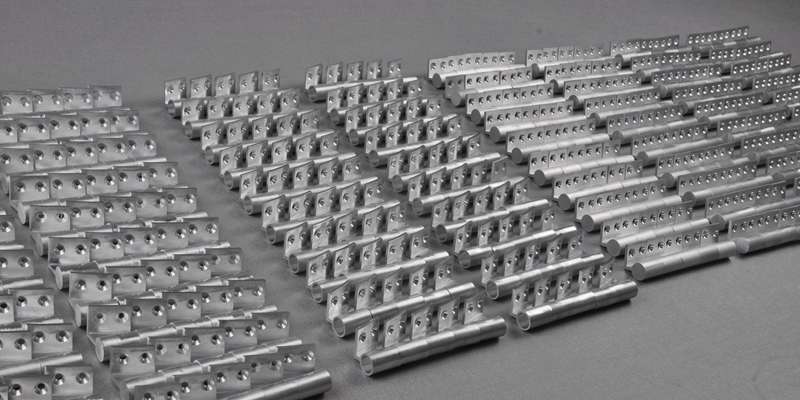

Low-volume production is a machining service used to produce a small number of parts from as low as 10 to 1,000 units. Most times, it serves as a link between prototyping and mass production for new and emerging products. This service is important for companies that produce specialized parts in small quantities.

Furthermore, It is an efficient way to adjust certain production practices as the quantity increases. With low-volume production, manufacturers can test for product flaws before making huge financial investments. Overall, low-volume CNC machining allows for further cost saving while making high-quality parts.

What Capabilities are Required for Low Volume CNC Machining?

The capabilities required for low-volume CNC machining include but are not limited to the following.

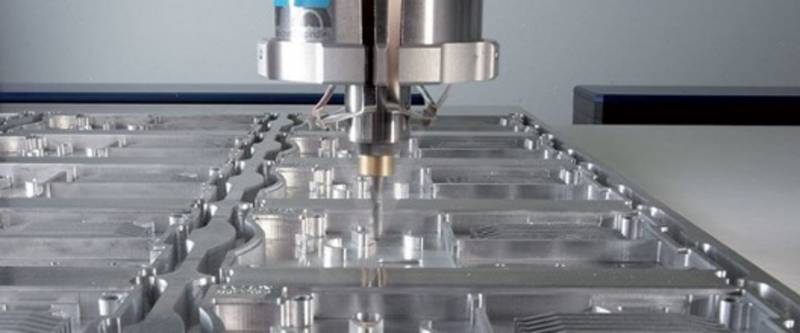

CNC Milling

CNC milling involves using CNC cutters to remove material from a workpiece. This gives the desired shape and design to the part. The movement and operation of the cutting tools are fully automated.

From wood to plastic and metals, CNC milling machines are compatible with many materials. Because the machine is automated, it is ideal for complex low, volume operations.

CNC Turning

CNC turning works in ways similar to CNC milling. In CNC turning, the cutting tools are stationary while the workpiece rotates around to create the part’s shape.

Manufacturers use CNC turning to make highly precise parts for low-volume production. It provides an excellent surface finish. However, the tool wears out easily and may need replacement as mass production begins.

Coordinate Measuring Machine (CMM) Inspection

CMM Inspection assures the quality of a low-volume part by measuring the dimensions using a probe to detect discrete points. This process is important for parts used in critical applications. By assessing a part after production, you can identify and adjust mistakes quickly. However, one ought to be skilled and experienced to operate the machine.

Mechanical Subassembly

The mechanical subassembly process is a critical aspect of low-volume manufacturing. This process is useful when the part is too large. It involves creating accurate smaller parts before assembling them as a whole. Hence, mechanical subassembly ensures that manufactured products are of the highest standard possible. With this process, manufacturers can modify a part’s design and function to meet the end users’ needs.

Finishing Services

Post-manufacturing finishing is a vital aspect of low-volume CNC manufacturing. Finishing services can range from plating and etching to heat treatment and passivation. These different processes help to improve surface flaws, adhesion, chemical, and corrosion resistance and increase a part’s hardness and durability.

Advantages of Low-Volume CNC Machining

Advantages of Low-Volume CNC Machining

Low-volume CNC machining is important for producing high-quality parts in a short time. This service has many advantages.

1. Short Lead Time

The time a product gets to market may determine its success. Low-volume machining shortens lead time. This property makes low-volume production the most appropriate for new designs.

Just as with other on-demand manufacturing services, you can produce a part in a very short time. With low-volume CNC machining, you can be sure of maximum profits before competitors’ products into the market.

2. More Precision

Low-volume CNC machining is fully automated. Hence, this process produces more accurate and precise parts. Additionally, it reduces the risks of physical and functional flaws. Because the parts produce meet tight specifications, it is the ideal machining service for the aerospace and medical industries.

3. No Tooling Investment

You do not need tools like a die or mold to produce parts when using low-volume CNC machining. Oftentimes, the cost of producing and maintaining these tooling systems is quite high.

Additionally, the tool processing time may increase a product’s lead time. Low-volume CNC machining is free of these shortcomings. This makes this process the most ideal to create parts in a short time.

4. More Post-Finishing Available

Surface finishing is essential because it may determine how a part will perform. There are many surface finishing processes available for low-volume CNC machined parts.

Anodizing, bead blasting, powder coating, and painting all help to improve the aesthetics and functionality of a part. However, it is important to choose the most appropriate method because it will determine how the part functions.

Tips for Low-Volume CNC Machining to Save Time and Cost

Tips for Low-Volume CNC Machining to Save Time and Cost

To get the best from your low-volume CNC machining, consider the following.

Choose the Right Material

For low-volume CNC machining, using the wrong material may increase the overhead cost of processing it. Though almost all materials are compatible with CNC machining, very hard ones need special attention. The ease of machinability is the determining factor when choosing a material to work on.

Using steel as an example, they are ideal for anything automotive because of their high strength and durability. However, high-carbon steel cannot be machined easily. It is important to use the most affordable and durable functional material

Avoid Thin Walls

CNC Machining is a time-consuming process, especially for novices. To maximize time, it is necessary to avoid thin and tall walls. Additionally, low-volume parts with thin walls require more capital investments and may have a negative impact on turnaround time.

Furthermore, thin walls require considerable expertise and high accuracy and precision. This is because the parts may warp or deform under stress. When you cannot avoid them, use the right material and tool for thin-wall machining.

Keep Simple Designs

It is important to keep the designs simple yet standard. When a part is complex, it is advisable to create it in smaller sizes before assembling them.

Additionally, the complexity of a part determines the type of tooling. Very complex designs require additional CNC machining tools. Also, complex designs may increase the risk of inconsistency and human errors.

Use Only Necessary Post Manufacturing Finishing

Surface finishing is the last step in low-volume CNC machining. There are many finishing options to select from. To avoid unnecessary expenses, it is important to use the most appropriate one for a part. Cost, product function and durability concerns may influence your choice.

For instance, anodizing and powder coating improves hardness and may be the most appropriate for parts intended for outdoor use.

Other Low Volume Manufacturing Processes

In addition to custom CNC machining, rapid tooling, and 3D printing are the most common processes manufacturers use for low-volume production.

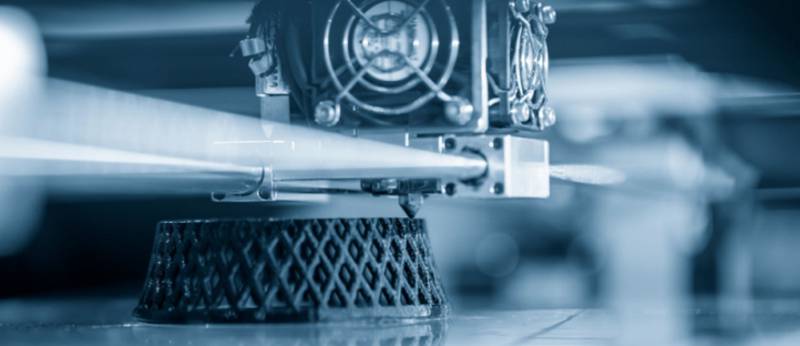

Low-Volume 3D Printing

Low-Volume 3D Printing

This additive manufacturing process offers rapid production for small-scale manufacturing. With 3D printing, there are no design restrictions. Each production stage gets completed quickly, and you can create parts in hours.

Furthermore, 3D printing allows for easy part design modification and generates little to no waste. However, 3D printing is not compatible with many materials and the size of the printed part is limited.

Low-Volume Injection Molding

This involves different manufacturing processes like low-volume injection molding or dies casting that needs a high-precision tool to create a part. Often, the materials are melted before shaping them.

Rapid tooling is an excellent approach to creating parts with complex shapes and geometries. However, the high tooling investment and expensive design modification are important shortcomings of injection molding.

Start With Wayken for Low Volume Machining Services

Using contract manufacturers for part production is a common approach. The challenge lies in choosing the best. With Wayken, low-volume CNC machining could not be easier. Our skilled engineers will help you move from prototyping to part production in days.

Also, we have an experienced and qualified team to help you get started with trial production. We will meet your low-volume machining needs from one unit to a few thousand. Get a free quote and let’s start a new project!

Conclusion

Low-volume CNC machining is a means to test a product’s functionality and customer preference before mass production. This service assists manufacturers in increasing the quantity of their product in the market gradually while making necessary modifications.

FAQs

Which CNC operation is best for low-volume production?

CNC milling and turning are basic CNC operations that use similar principles. Both have different applications, and none should be considered a better option.

What are high-volume and low-volume production?

High volume production process manufactures more than 1,000 parts per batch while maintaining quality. With this process, you spend less to produce more.

However, low-volume production manufactures significantly fewer parts. Most times, it is a link between prototyping and the mass production of emerging products.

What is the ideal method for low-volume production?

The method of choice for low-volume production depends on some factors, but there is no standard way to choose the best. For example, CNC machining and 3D printing are cost-effective processes because they produce parts without expenses associated with tools.