Optical Machining for Prototype Light Guides

Automotive lighting increasingly incorporates aesthetic LED and optical systems to enhance vehicle light control. We manufacture complex, high precision optical prototypes in compliance with industry standards, using our CNC precision milling expertise.

Our understanding of requirements:

- The parts are machined as a whole as possible to meet the geometric modeling design.

- Understand standard optical design features to manufacture functional and aesthetically pleasing lighting prototypes.

- Achieve original designs and meet design tolerances through precision machining of optical details.

CNC Machining of Complex Optical Component Geometries

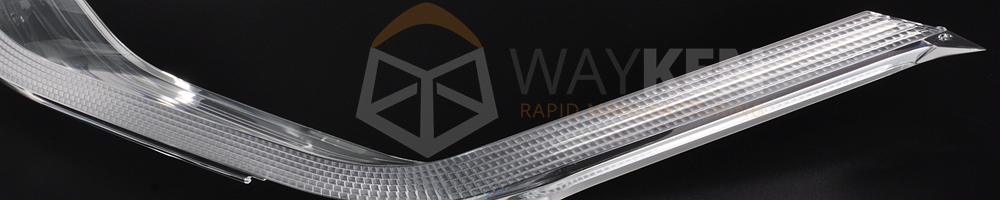

Perfect Lit-Up & Homogeneous Output

Sophisticated optical machining of the light guide prototype for uniform linear light transmission requires:

- Minimum machining radius R0.1mm for optical details

- Surface tolerance of optical area ±0.02mm

- Surface roughness after CNC machining and mirror polishing, Ra0.1μm, and Ra0.02μm, respectively

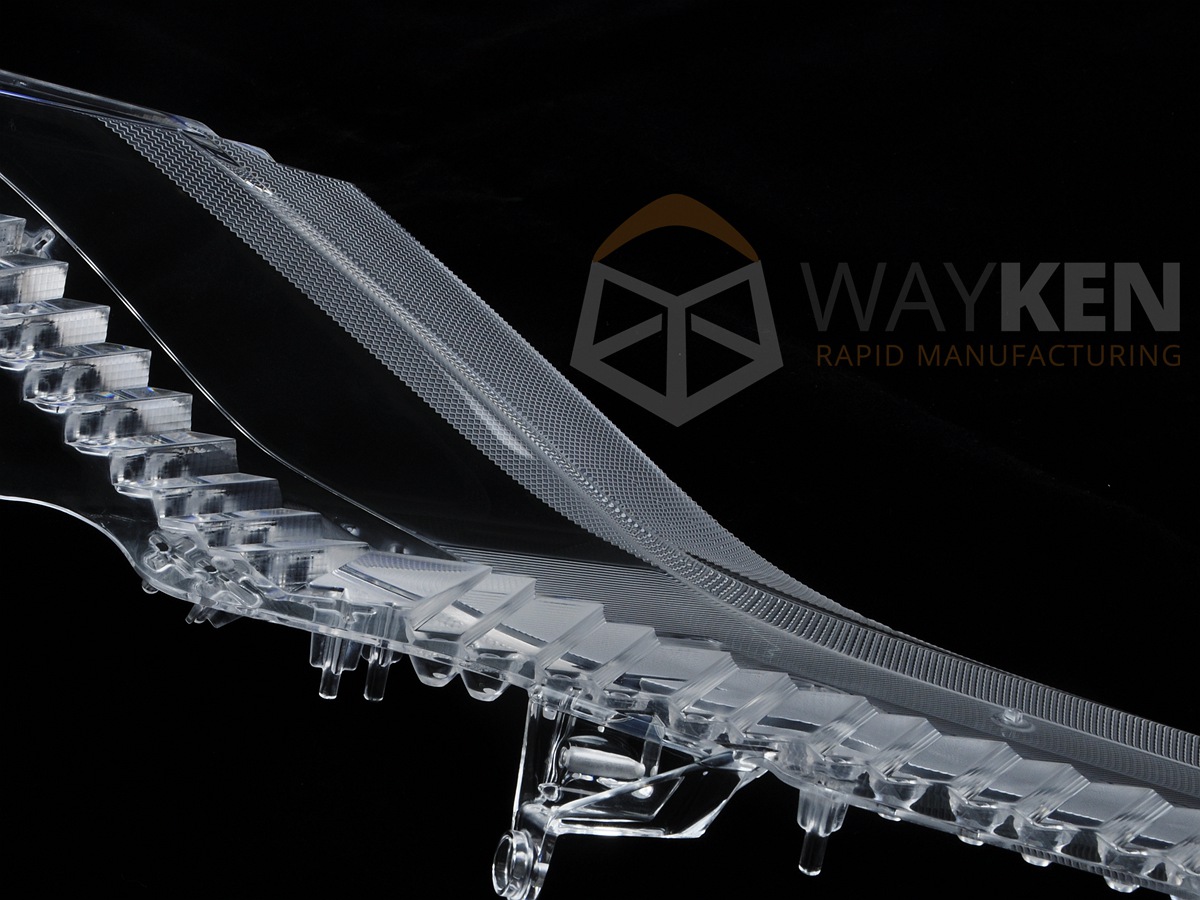

5-Axis Precision Machining for Thick Wall Light Guides Perfect Light Distribution and Diffusion

As automotive lighting technology advances, light up effects and visual perception are more and more attention. More complex geometric shapes and dense diffusion patterns go into designing thick-walled light guides and other optical structures.

We provide 5-axis precision CNC micro-milling for light guide prototypes. They are ideal for machining optical components with high aspect ratios and complex geometries, and offer excellent machining accuracy and flexibility. With vast years of CNC programming and post-processing experience, we conquer manufacturing challenges while producing stunning and efficient lighting effects.