Multi-Solutions for Lamp Lens Prototyping

Clear Prototype for Headlamp & Taillamp & Foglamp

Lamp lens prototyping requires expertise and attention to the intricate details of each lens, reflective surface and housing assembly to truly reflect the original design. we have a team of experienced technicians that handle customers’ specific product design requirements and provide complete manufacturing support.

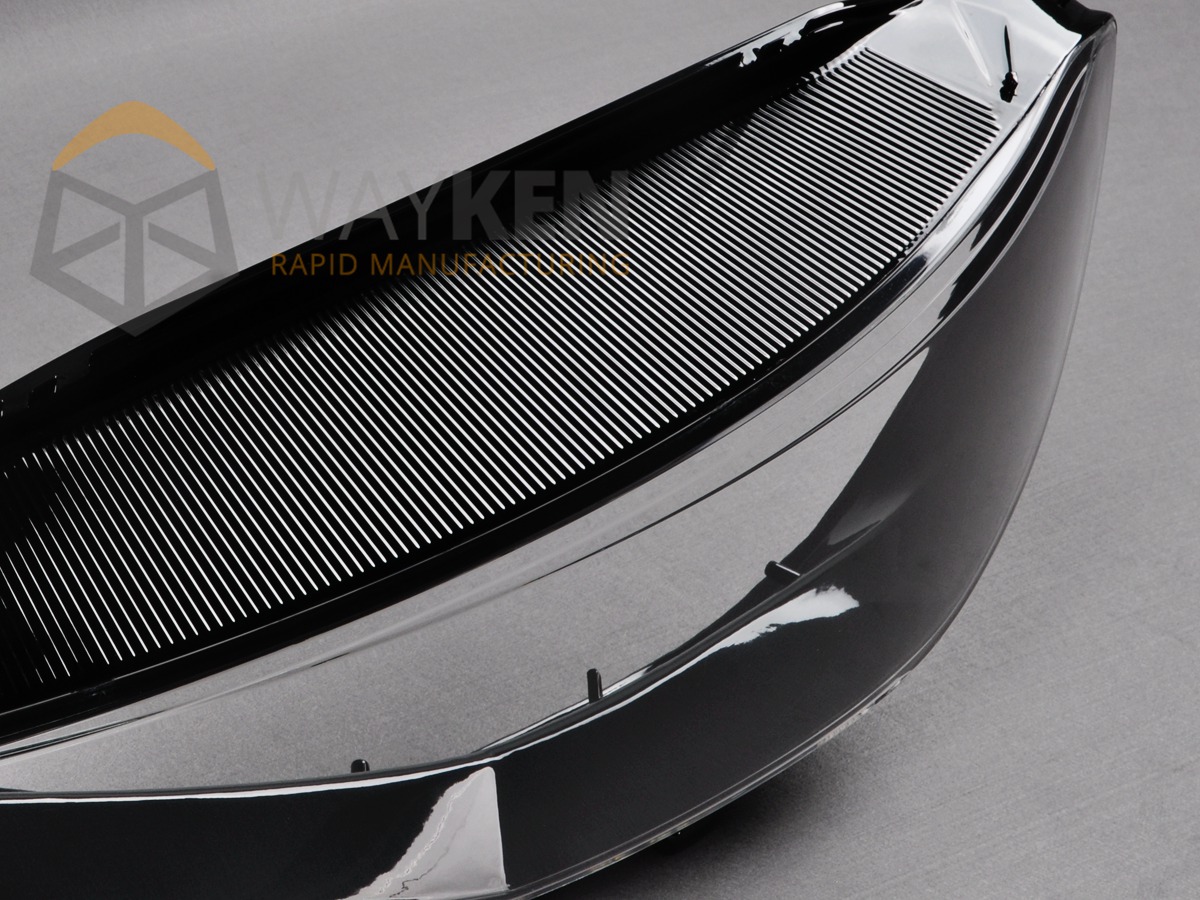

- Split machining solution of large-sized components

- Overall CNC machining of ultra-thick transparent sheets

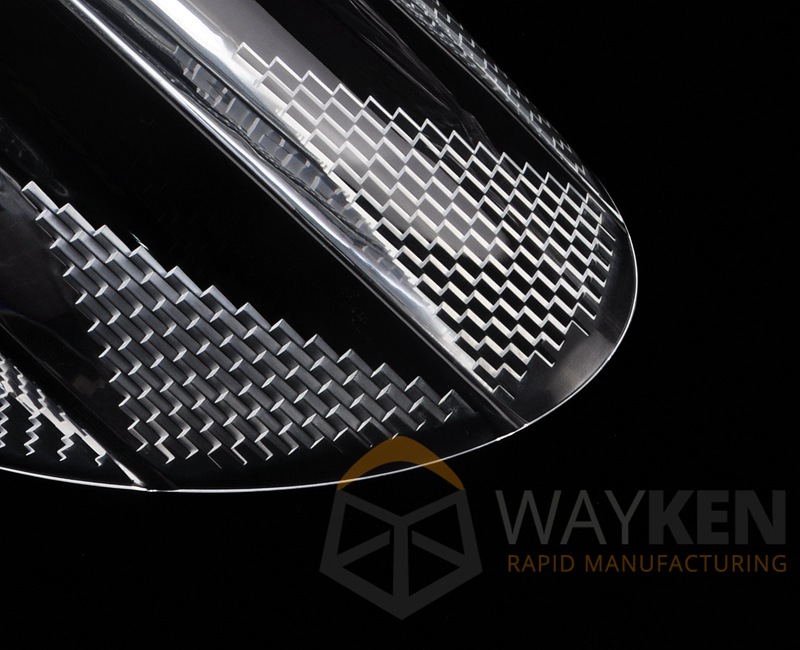

- Ultra-precise of thin-walled curved surfaces of lamp lens

- Minimum machining radius to ensure optical details

- Seamless hand-glueing and mirror polishing.

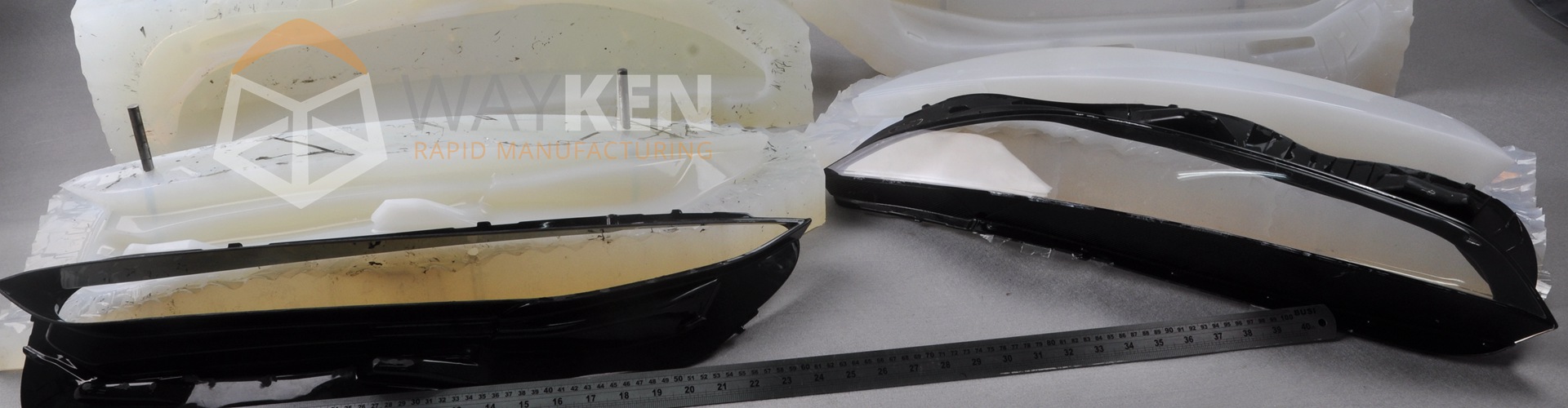

- High-volume silicone moulding and flawless casting of transparent parts

- 2K painting and vacuum casting that simulating two-colour injection moulding process.

Prototyping and Post-Finishing of Complex Surface of Transparent Lens

READ MORE AUTO LIGHTING PROTOTYPINGThe Technology of Rapid Prototyping and CNC Machining for Lamp Lens:

- Using acrylic-like transparent resins by low-cost SLA for rapid prototyping

- Combining mirror CNC machining of PMMA and PC plastic materials with hand polishing to provide optimum transparency and light transmission

- Finished CNC-machined surfaces with a tolerance of ± 0.05mm with a minimum machining radius of R0.1mm for optical details

- Machined surface roughness Ra0.2μm, mirror polished to Ra0.02μm

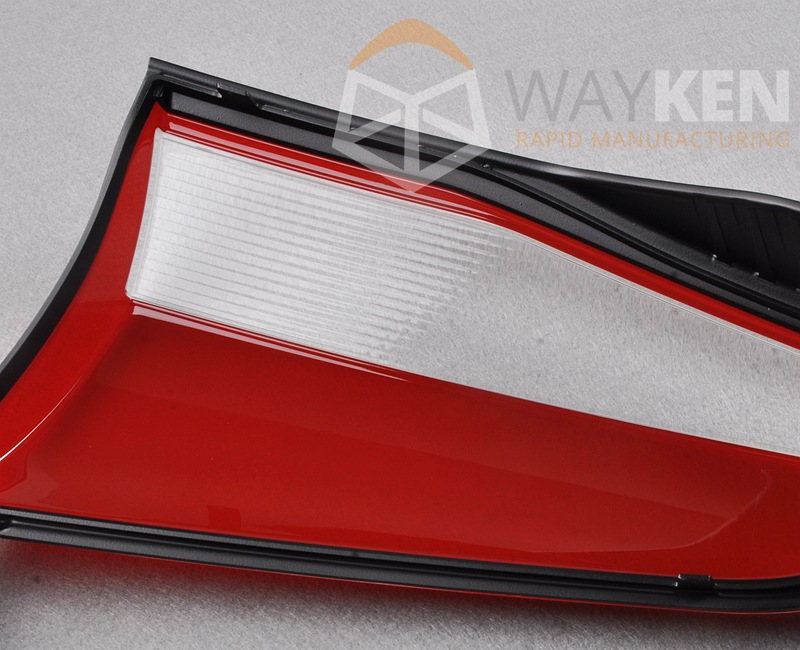

- After split and bonding with some opaque materials, like ABS, the lamp lens can be painted in various colours to achieve a simulated 2K injection molding.

The Dual Colour Lens Realized by Overmolding Vacuum Casting Technology

The production of lamp lens is usually done using 2K Molding, which involves two injections of different materials (or colors) on the same injection molding machine to form a single injection molded part, and requires a dedicated 2K injection molding machine.

When lamp prototyping stage, we implement the overmolding process in silicone molds to achieve a single urethane part with a two-colour or two-component lamp lens. Usually, two master pattern and two silicone molds are made, and the parts are cast twice.

In this relatively complex production process, we have a professional team to control the quality and progress of the project. We pay attention to the structural characteristics of the product and process analysis, control the dimensional accuracy and surface quality, so the product effectively avoid the common defects of secondary molding, including deformation, lack of material, poor welding, peak, bubbles, shrinkage, etc.

We pride ourselves on supporting our customers with advanced excellence in automotive lamp lens prototyping.

Contact Us for an Instant Quote