Machining Capabilities for CNC Precison Prototypes and Parts

WayKen Rapid Manufacturing is committed to offering customized and precision CNC milling and turning capabilities to automotive, aerospace, medical, robotic, and consumer electronics industries.

Our CNC Processes

From simple to complex designs of machined parts, WayKen’s CNC machining processes can meet your requirements efficiently and at an affordable price.

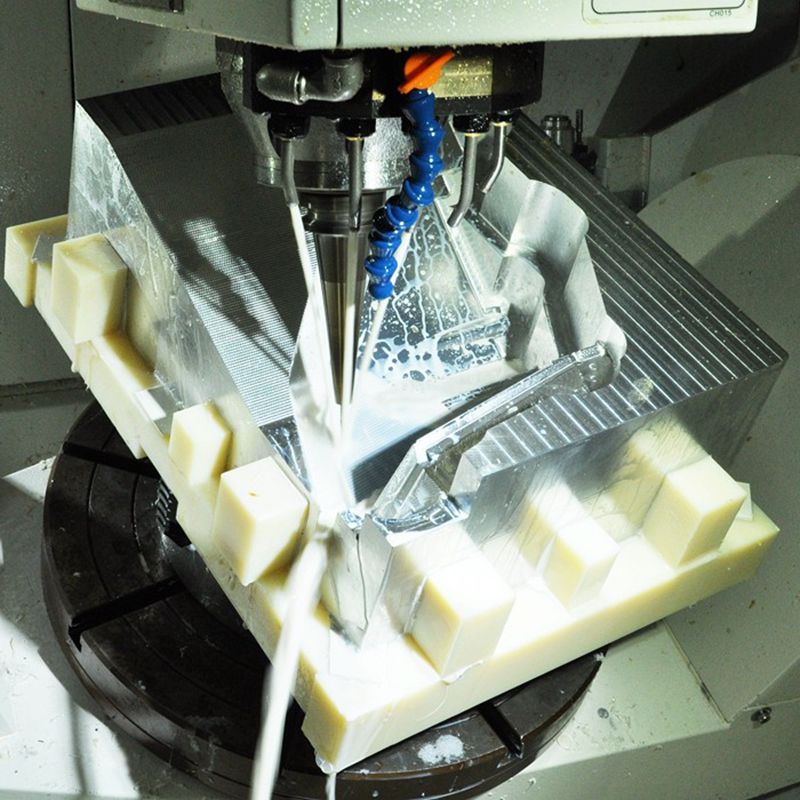

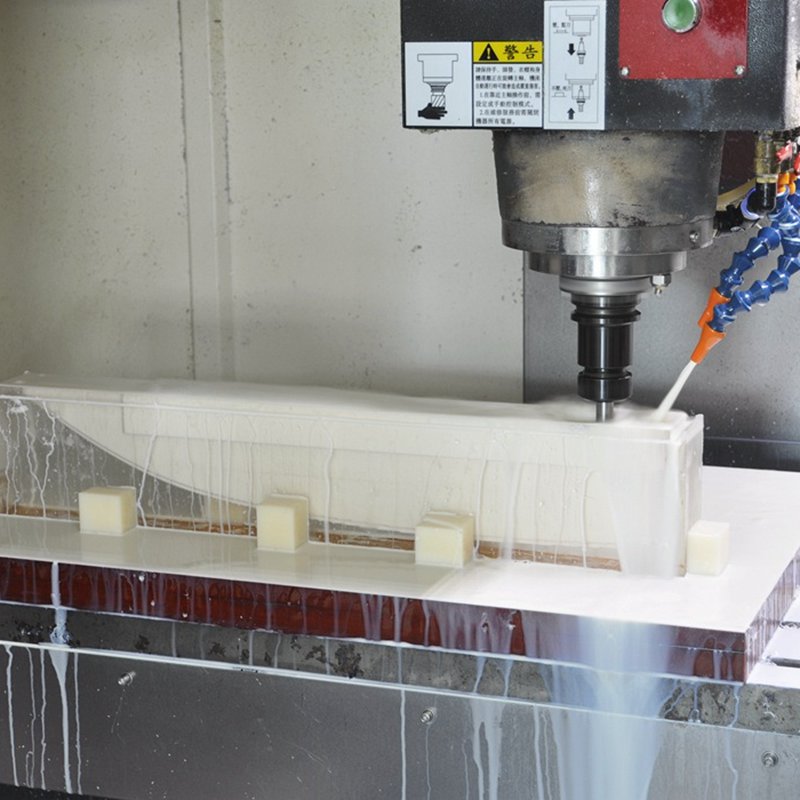

CNC Milling Services

CNC milling refers to using cutting tools to machine solid plastic and metal blocks. This operation involves a multi-axis machining process, our 3, 4, and 5-axis milling capabilities can handle from simple to complex prototypes and parts with precision tolerances.

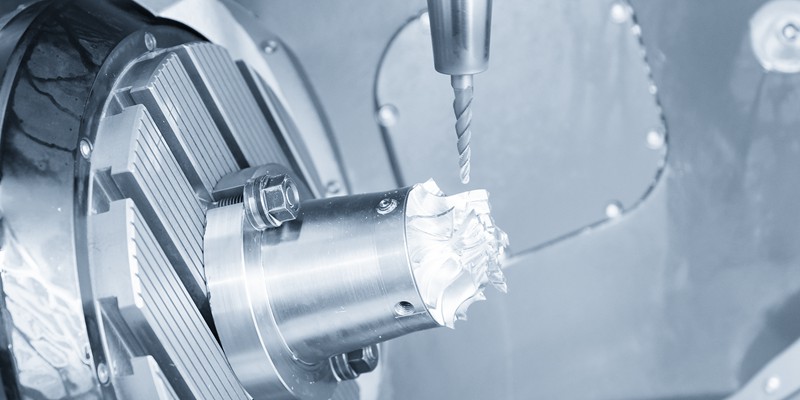

CNC Turning Services

CNC turning is subtractive manufacturing that uses rotating cutting tools to process metal and plastic stock to get products with cylindrical features. You will get CNC turned parts with fine external geometries, precision internal bores, and smooth finishes at WayKen.

CNC Precision Machining

Need to achieve a tight tolerance of ±0.01mm or higher, WayKen boasts a team of expert technicians with extensive knowledge in precision machining techniques. We are ready to produce complex parts with high accuracy for your projects.

5-axis CNC Machining

Utilizing 5-axis CNC machining enables the processing of complex parts with multiple side features in a single setup. This approach yields many benefits, including enhanced machine utilization, minimized setup requirements and cycle times, and improved quality standards.

Quality Control & Certifications

WayKen’s quality management system meets the ISO 9001:2015 and ISO 14001 certification standards. We ensure quality through each project phase and provide customers with exceptional quality, thanks to our strict quality control processes and state-of-the-art testing equipment.

WayKen supports metal machining services for a variety of materials, including aluminum, magnesium, titanium, zinc, steel, and stainless steel. We are always ready for the challenges of tight tolerance for precision CNC machining.

With more than 30 engineering-grade plastics, from visual design models to functional prototypes, we specialize in complex surface CNC plastic machining and fast turnaround to deliver your plastic parts and prototypes.

CNC Machining Capabilities at WayKen

WayKen’s factory has one-stop CNC machining capabilities to produce any volume of complex and precision prototypes and parts.

CNC Prototyping Factory

Skilled Employees: 50+

Workshop: 2000 sq.m.

CNC Machines: 16 units

(HASS, JINGDIAO, JIRFINE)

Prototype machining allows your design team to closely simulate the appearance, function, and material properties of the final product, and test the suitability and manufacturability of components to prove and perfect their design.

CNC Production Factory

Skilled Employees: 50+

Workshop: 5000 sq.m.

CNC Machines: 96 units

(GROB, GF, JINGDIAO, HASS, JIRFINE, CATO)

Finding a custom manufacturer that offers “made to order” can be a valuable addition to your supplier system. Precision, quality, and affordability at any volume. Our team responds quickly to accommodate your needs.

Why Choose WayKen to Handle Your CNC Machining Projects?

WayKen makes every effort to meet the needs of a wide variety of customers across industries and gain experience and broad knowledge in how to manufacture prototypes and parts exactly to customer specifications.

Our engineers will offer cost-effective and reasonable proposals for design, materials, manufacturing processes, and manufacturability. Quick response within a few hours from a technical team, with proactive and practical DFM, order reviews, and customer communication.

Leveraging the PRD industrial clusters in China, reliable supply chain resources, and comprehensive and flexible production capacity. We can offer different types of precision CNC machining services including milling, turning, EDM and wire EDM, and surface grinding, etc.

WayKen insists on providing efficient services. Our finished product pass rate is≥95%; On-time delivery rate is≥88%; Customer satisfaction is≥90%. From prototype to production, faster turnaround, more consistent quality, and lower costs.

We also offer complete one-stop finishing services including sanding, polishing, blasting, painting, and printing. Also specialty surface treatment of laser etching, anodizing, electroplating, chroming, chemical finishing, and powder coating.

My prototype part arrived yesterday. Thank you very much for the fast turnaround time. The part is 100% perfection!

I am very pleased and will happily recommend your company to anyone I know looking for machined parts.