Turn your design into a physically existing object with the rapid prototyping process. Present your ideas to your audience more precisely and visually.

Application of rapid prototyping process

In the project development stage, the production of both structural and exterior prototypes is crucial. The prototypes are the most visual representation to check whether the appearance and structure design is reasonable. It could find out the preliminary problems, provide a visual inspection basis for volume production, and effectively avoid the risk of direct volume production.

In the early days, most of the prototypes were made by hand due to various condition limits. Which is leads to a long processing cycle of the prototype. And quite difficult to strictly meet the dimension requirements of the structure. So the function of checking the reasonableness of appearance/structure is greatly reduced.

The development of the rapid prototyping process

The development of the rapid prototyping process

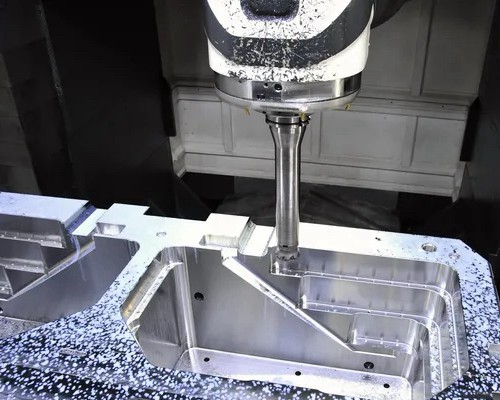

The rapid progress and development of science and technology provide better technical support for the prototyping process. The popularity of CNC machining center (CNC), CNC lathe, CNC milling machine, laser cutting machine, etc., as well as a variety of post-processing equipment, makes the prototype production has a real sense of “accurate”, “fast” and “gorgeous”.

Rapid prototyping process solutions

On the other hand, with the increasingly fierce competition in the market, the speed of new product development is increasingly becoming the prime contradiction of competition, and the modern prototyping process can effectively improve the new product development. There are three main ways of rapid prototyping.

CNC (subtractive manufacturing)

The advantage of CNC machining is that it can accurately reflect the information instated on the drawing. It is suitable for a prototype with high technical requirements and high surface quality, for example, car lamps in the field of automotive prototypes.

At present, CNC machining technology has become an industry in the prototype manufacturing field. And it is the mainstream of rapid prototyping, mentioned in the industrial design field, and generally refers to CNC machining.

3D Printing (additive manufacturing)

3D printing was born in the last century and has been widely used in the manufacturing industry since then. Printable materials include plastics and metals, but there is still room for improvement in materials. On the contrary, this also means that the development trend of 3D printing is promising.

For now, 3D printing prototypes made by plastic due to material limits can not bear high temperatures. They are a little brittle and have other shortcomings. Usually suitable for verification of the structure. If the prototype has many refined post-processing requirements, it may be a better choice to complete by another prototyping process.

Rapid mold manufacturing

① Vacuum casting is also called urethane casting. It is suitable for trial sample parts with more complex structures, uniform wall thickness, and functional requirements.

② Injection mold is a kind of tool for producing plastic products. It can give plastic products complete structure and precise dimensions. Injection molding is suitable for batch processing of certain complex-shaped parts.

③ Low-pressure injection molding is suitable for the production of cover/lid parts with simple structure, large thick-walled parts, and parts with uneven wall thickness.

Summary

No matter the prototype presented by which way eventually, pre-exploration and communication are extremely crucial. It usually needs to combine the process of final volume production for prototype verification. More preparation may quicken the speed in doing work. Do a good pre-research job at the design development stage, will reduce the risk of the follow-up volume production.