Before going into mass production of any product, it’s essential to develop a prototype. Prototyping is part of the design verification process in product development. Depending on your target market or industry, the prototype can either be for display or a functional one.

A functional prototype is a product model created to test a concept. This visual prop is commonly used in product development to improve new designs for the consumer. They give the authentic feel, look, and working of a specific part in the real world. You can create one using CNC machining, 3D printing, rapid tooling, or fabrication.

During the manufacturing of automotive parts, functional prototypes are an essential part of product development. Why is prototyping so crucial in this industry? Let’s find out.

How to Create a Functional Prototype

In automotive prototyping, several technologies are used to create parts for market testing. These technologies bring the designs to life within a short time. Here are some of the techniques used by manufacturers to develop functional prototypes for the automotive industry.

1. 3D Printing

Car parts can be made using different materials using 3D printing. This technology builds three-dimensional prototypes that can be used in product testing.

2. CNC Machining

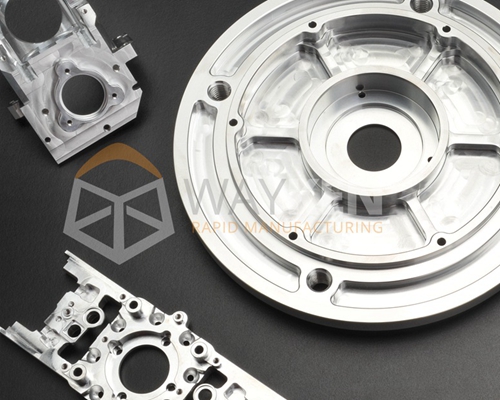

Computer Numerical Control techniques are incorporated in automotive prototyping by most manufacturers. Using CNC machines, they can create functional prototypes that have precise dimensions and suitable materials. In addition, most car parts require surface finishes for excellent aesthetics that come under CNC processes.

3. Vacuum Casting

3. Vacuum Casting

This technology allows for quick production. By using silicone molds, engineers can produce a functional prototype for testing purposes. This method is used for small batches.

4. Rapid Tooling

However, if you need several prototypes for more significant production, you can use injection molding, which produces parts for testing much faster. This is a cost-effective method to more quantities of the prototype that are similar to the end product.

Why Use Functional Prototyping in Automotive Product Development

The automotive industry is a highly competitive sector. Because of this, car manufacturers have to stay on top of the game by introducing new designs and innovations. Here are some of the essential roles of having a prototype during product development.

· To Verify New Designs

A functional prototype helps the companies validate these new designs and parts before going into mass production. Then, if the parts work efficiently, they can add it as an end product on their cars.

· To Conduct Market Research

Due to the competitive nature of the automotive industry, prototypes are used for customer research. They can be presented to focus groups on testing their functionality before an official launch.

· To Check for Accuracy

Automotive parts need to be very precise. Creating a prototype helps identify errors in terms of design, dimensions, or materials used. Automotive prototyping is essential in making sure that the parts produced are functional.

· To Identify Security Issues

There need to be high levels of safety in the automotive sector. Having functional parts during the product development phase is essential in ensuring the safety of the cars. Once any errors are identified, the engineers can improve production.

Automotive Product Development Phases that Require Prototyping

Functional prototypes are made in different phases of product development in the automotive industry. However, all these steps are essential for the engineers, car manufacturers, and end-users of the product.

1. Concept Validation

This first step in automotive prototyping allows for creating initial designs that the company can present to stakeholders, clients, or the internal company team. This item is a basic prototype that visualizes the design idea before mass production.

2. Pre-Development Phase

During this phase, automotive engineers create a functional prototype that can be fitted in an automobile. This process helps the engineers examine the part’s performance against other components in the car and what needs to be altered or replaced.

3. Production Phase

Using the processes of creating a functional prototype such as CNC Machining, designers can now develop a final functional prototype for the cars. At this stage, designers also examine the production processes to determine the costs involved and the best materials to use.

4. Consumer Test Phase

Once the automotive prototype is ready, you can present it to customers or a focus group for testing. Engineers can get valuable customer feedback on any challenges that arise and what the end users would like improved.

5. Safety Test Phase

5. Safety Test Phase

Due to the sensitive nature of the automotive industry, safety testing is a necessity. This process is the only way to ensure that the functional prototype is safe for end-users. In addition, engineers can correct any issues to ensure customer safety.

6. Manufacture Validation

Once the prototype passes the safety test, production can begin with all the new improvements. The final parts are now installed in the car and launched in the market.

Summary

Prototypes play a significant role during the manufacturing process. Product development relies heavily on these low-volume designs to test the market, get funding from investors or approval from stakeholders. Before going into mass production, automotive manufacturers create a functional prototype to test the workability of these parts.

Creating a prototype is a cost-effective method for both manufacturer and client because it helps identify problems before full production. The automotive industry is a crucial user of prototypes, especially before the launch of new designs.

If you need a detailed functional and working prototype to test your design, contact us at WayKen to get a quote and get started.