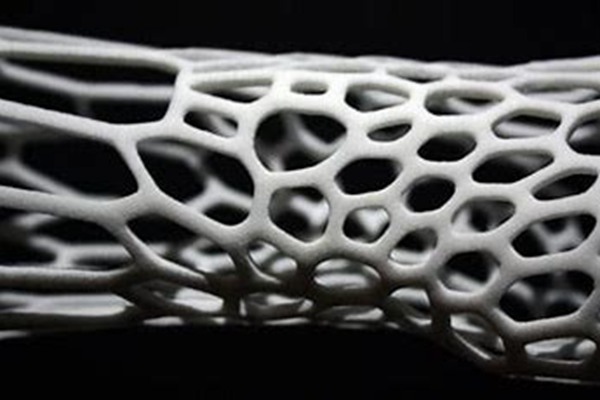

At present, there are more than 200 kinds of 3D printing materials available, but it is far from enough to deal with the complex products in reality. If these 3D printing materials are classified, they can be divided into petrochemical products, biological products, metal products, lime concrete products, and other categories. Some commonly used 3D printing materials in the 3D printing industry include ABS plastics, PLA plastics, PMMA, Nylon aluminum powder material, stereolithography, stainless steel, and other metals like silver, gold, and titanium. High-performance engineering plastics like ULTEM, PEI, PAEK, and PPSU show outstanding advantages in terms of lightweight, heat insulation, electrical insulation, and durability. In many cases, they can be alternatives to metal alloys for economical and efficient reasons. 3D printing technology brings solutions for industrial manufacturing applications in design, and custom low volume production due to its low cost and lightweight. And it has been proven in Formula one racing cars. This article is going to discuss some examples of 3D printing material applications of lightweight parts for formula one racing cars and see how 3D printing technology of high-performance engineering plastics makes low volume terminal custom auto parts production possible.

From final parts to spare parts

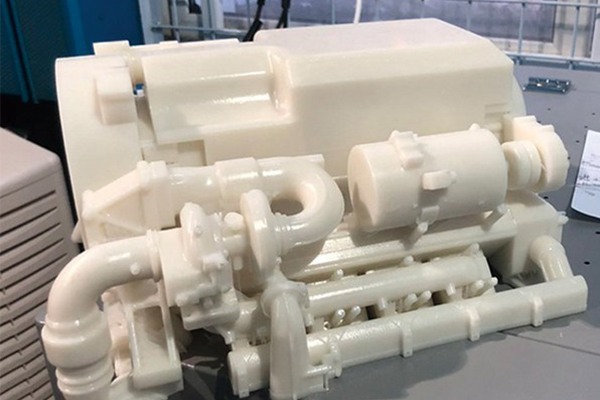

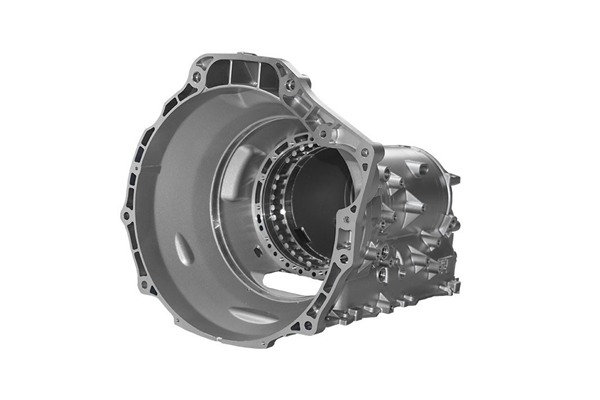

When the new formula one racing car E0711-11 EVO is shown to the public, we can see that a large number of high-performance engineering plastics are used to 3D print the components. All of the parts for EVO have been tailed-made in the past two years. A new wheel assembly that performs better in both aerodynamic and kinematic perspectives has been developed by the team members. New brake calipers and 3 D-printed components are applied to the body system. High-performance 3D printing materials are again tested reliable and feasible in industrial and engineering fields.

Diverse applications of 3D printing

3D printed components are used in different places on the new racing cars. Compared to traditional manufacturing, 3D printing enables car components to be made much faster, and a huge amount of spare parts are prepared for the new season in case some parts are damaged during the race. EVO is the first racing car that has so many 3D printed components using high-performance 3D printing materials. Compared to CNC machined parts, 3D printed ones weigh 50% less and these high-performance 3D printing materials can be used in racing cars with sufficient mechanical properties. Car parts can be printed on-demand at a low cost in a short delivery time while 3D printing provides the extraordinary capacity to modify designed components quickly and cost-effectively. In addition, plastic parts do not conduct electricity so they have a more promising future in electric racing cars production than metal parts.

Lighter, faster and cheaper

3D printed parts are used in battery systems, braking systems, as well as power systems. The E0711-11 EVO has to withstand extreme conditions during the race and uses high-performance engineering plastics to meet excellent mechanical properties, high chemical resistance, and high strength weight. Metal car parts used in previous racing cars such as brackets and gaskets are replaced by plastic parts printed with high heat resistant 3D printing materials such as PEEK PPSU or ULTEM. Green Team also customizes some lids and housings for different components suing materials like ABS and PC. It’s a fact that all of the parts in racing cars have to be strong enough for resisting extreme conditions and without qualified 3D printing materials, it would be impossible to make high-standard auto parts.

How can high-performance 3D printing materials be applied to industrial manufacturing more widely?

No doubt, Formula One racing manufacturing technology is at the forefront of developing manufacturing technologies, and in collaboration with the racing manufacturing team, machine tools and additive manufacturing equipment manufacturers have also refined advanced manufacturing processes to further confirm their competitive position in the market. There is no doubt that motorsport remains one of the technology accelerators. 3D printing technology has become an essential part of the modern design, prototyping, and manufacturing of racing car parts over the past ten years. Additive manufactured components have been refined and improved in motorsport and have been extended to business situations gradually.