Manufacturers and product designers rely on CNC machining to produce visual and functional prototypes before product production. Prototyping machining is an effective method for getting product samples at a relatively lower cost.

This article discusses the concept of prototype and prototype machining, why you should use CNC machining for your prototype, various prototyping processes, and tips to get the best from CNC prototyping. Let’s get to it!

What is a Prototype?

Prototyping refers to the process of creating a range of pre-production sample products. They allow one to test the accuracy of engineering simulations, evaluate form, fit, and function, validate manufacturability (DFM & DFMA), and test market response via focus groups. As such, prototyping does not mean creating a single perfect pre-production unit, but rather it is a process that starts with low-fidelity plastic parts and moves all the way through to a final fully-functional prototype.

During this process, the design is continuously evaluated and iterated upon. One of the most efficient methods of streamlining this process of iteration and continuous improvement is to outsource the manufacturing to prototype machining services that not only have all the required machinery but also the expertise to help guide these design iterations to the final product.

Types of Prototypes

There are many different prototype classifications, but the three listed below are the most common in physical product development.

- Prototype Concept Models– Prototyping can be used as a tool to further evaluate conceptual designs. If, after the design stage, there are still too many viable concepts, concept prototypes can be manufactured to evaluate their look, feel, and functionality from a high-level perspective without delving into too much detail. CNC machines can help iterate between these early concepts since cheap plastics are easily machined and require minimal investments in time and finances.

- Functional & Working Prototypes– A working prototype is a fully-functional prototype created to represent all the features of the conceptual design. Whenever possible, it is important that a working prototype be created with the same manufacturing techniques as the final product. This allows engineers to see where possible manufacturing or engineering challenges may require design changes early on in the product development process. These prototypes often contain multiple materials and thus require a wider range of manufacturing equipment to create, and CNC machines can machine many different materials from aluminum to engineering plastics.

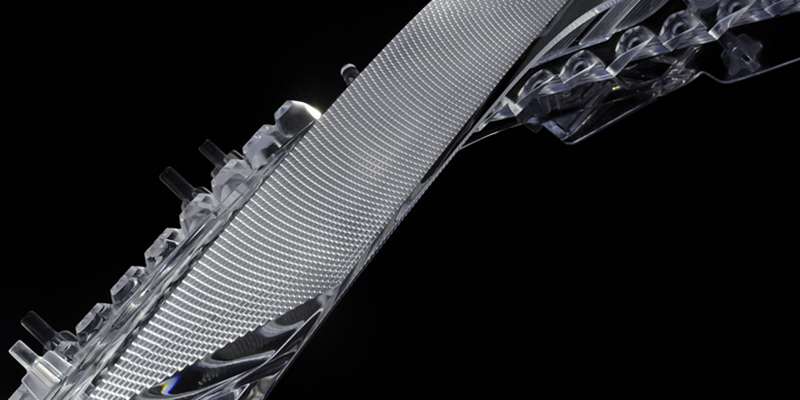

- Visual Representation Prototype– A visual prototype is created to showcase a product’s design intent by depicting its general shape, size, material makeup, and design. CNC machines can not only be used to create the individual components of the prototype but can also be used to create master patterns for parts that can then be cast in urethane to better represent the materials to be used in production. Another example is the machining of optically transparent prototypes using clear acrylic and polycarbonate. Transparent prototypes are sometimes used to showcase the internal workings of a product while still presenting the design of its enclosure and structural components.

What is Prototype Machining?

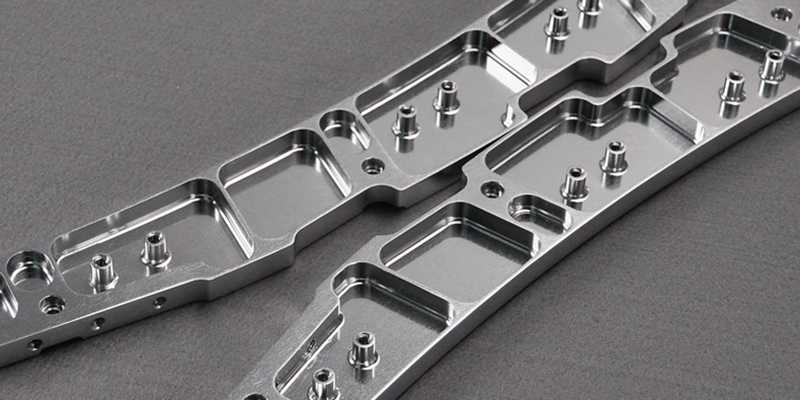

Prototype machining involves the creation of small batches of testing or final products before entering the market. CNC machining prototype helps to showcase visible information about final products. It conveys how a digital design will appear when manufactured, revealing all its specifications.

In addition, these machined prototypes are helpful for market and functional product tests, and they help check for defects and design errors to find out if the product fits the purpose of the design perfectly. As a result, design iterations can be easily made to improve the product’s functionality and customer satisfaction.

Why Choose CNC for Prototype Machining?

Why Choose CNC for Prototype Machining?

Computer numerical control is an ideal process for precision prototyping machining. Although 3D is a dominant technique amongst most manufacturers, CNC machining remains a reliable and effective process for superior-quality prototypes. In addition, CNC prototype machining is compatible with many materials.

CNC for prototype machining employs computerized controls to oversee the cutting head’s movement and the workpiece. It executes operations at the slightest intervals, unlike alternative prototyping techniques. At the same time, it is an efficient method with fast and excellent prototyping results. CNC for prototype machining helps you run a cost-effective operation with higher efficiency.

How to Start CNC Prototyping: Step by Step

There are several steps involved in making CNC machined prototypes. Here is a detailed break-down of it all:

1. Design Ideations

Drafting the CAD model design is the crucial step in CNC prototyping. Here, you have to create multiple designs perfect for the product. These ideations may include product dimensioning and positioning of its features, design for testing (DFT), design for manufacturing (DFMA), etc. This is because only efficient designs make it easy for the next stage.

2. 3D File Generation

CNC manufacturing depends on the generated 3D file, such as CAD model designs. Hence, the approved designs need to be transformed into a 3D file that the machine can understand. These 3D model designs determine the final workpiece’s dimensions, features, and aesthetic properties.

3. Identification of Manufacturing Sequence

Once the 3D model is ready, the next thing is to identify the most suitable machining process for adding each feature to the workpiece. Also, you have to decide the production sequence to create the prototype using a seamless CNC machining cycle.

However, different manufacturing methods like CNC milling, CNCN turning, CNC drilling, and more are involved in CNC prototype machining. Therefore, you should determine the sequence of their machining according to the specific workpiece.

4. CNC Programming

Manufacturers use a CNC program to provide the succession of CNC production processes and tool operating commands. The program usually includes G-code and M-codes, which give the CNC machines instructions on which tool to use, the distance of tool travel, the number of runs, cutting depth, feed rate, etc. The CNC program allows the automation of CNC prototyping based on the product’s specifications.

5. Prototyping

When the CNC program is ready, the programming is inserted into the numeric control panel of the CNC machine. The seamless CNC machining process begins when you mount the workpiece on the tool, and the machine is preset to an operation mode. The multiple CNC machining processes performed on the workpiece help to achieve the desired product with exact specifications.

The prototype can be a fully-functional product or a trial. Manufacturers make fully functional prototypes by machining their components individually and assembling them using design for assembly(DFA). This step is suitable for prototypes with mechanical linkages, and interconnected parts.

6. Testing

Testing is the terminal and most essential step of CNC prototype machining. The main aim of the prototype CNC machining is to test the functionality of the preferred workpiece and to inspect for defects and scope of failure. Once product experts test and approve the CNC prototype, the final product makes it to production. However, if the machined prototype fails to fulfill all requirements, the second-best ideation of the prototype is selected and machined.

Various CNC Prototype Machining Operations

Various precision CNC prototyping processes help to get the best prototyping results. Here are common CNC machining operations:

1. CNC Turning

1. CNC Turning

CNC turning is a prototyping process that involves using a lathe tool to form detailed prototypes and final products with cylindrical features. In this process, the workpiece rotates close to the stationed cutting tool instead of turning the cutting tool to remove excess material from the stock material.

The turning machine uses a single-point cutting tool to cut material from the bar stock creating cylindrical parts with a specified diameter. This process can machine linear features on the workpiece’s exterior and interior edges- tapers, slots, and threads.

2. CNC Milling

CNC milling is a subtractive process involving milling machines with multipoint cutting tools. These CNC machines cut materials from metal blocks and solid plastics to form prototypes with varying geometries according to design. Each cutting point rotates to make a sharp cut with varying length and shape on the workpiece.

The tools make shallow cuts, broad cuts, or flat-bottom cavities to create the parts according to design when milling. The axes used by the machine depend on the prototype’s complexities, and the machine has additional axes that enhance its movement, allowing more precise cuts.

3. Multi-axis Machining

3. Multi-axis Machining

CNC multi-axis machining is a versatile and practical prototyping process. There is an extensive list of CNC machining technologies, such as 4-axis, 5-axis, and up to 9-axis. These multiple axes enable the production of prototypes with complex specifications. In addition, the higher the number of axes a CNC machine, the higher its capability to machine difficult parts and provide high tolerance.

Advantages of CNC Machining Prototypes

CNC prototype machining is a flexible machining process with desirable results. Whenever you are considering which machining technique to choose between CNC machining and alternative prototyping processes, here are some advantages of CNC machining prototypes:

High Precision and Accuracy

CNC machines are part of the most accurate machining technologies with high precision. It is a fully automated process that helps to eliminate human errors while machining CNC prototypes.

You must create 3D CAD models of the designs, allowing a CNC machine shop to manufacture workpieces to meet the product requirements. These CNC machines can fabricate prototypes with a tight tolerance of ± 0.01mm or even little, which is more accurate for most prototyping requirements.

Time-Saving Process

Using a CNC machining service does not take more than enough time to complete because it does not need any mold or time-consuming requirements. CNC technology saves time and plays an essential role in producing prototypes.

Furthermore, it is easy to modify design files to make prototypes with the required specifications and test them. All these cycles can be completed within a little time.

Consistency and Repeatability

CNC machining is an automated process that uses software-controlled production to create prototypes with the preferred specification. Compared to alternative prototype processes, CNC prototypes have high repeatability. As a result, all products manufactured using the same process and design possess exact properties.

In addition, repeatability is crucial for prototype machining centers, and prototypes are expected to bear identical features to the final products. As a result, accurate imitation is possible only with the tight tolerance that CNC machines provide.

Extensive Material Compatibility

CNC prototype machining supports many material options, unlike 3D printing. These material options usually range from the hardest alloys and metals to materials such as plastics and wood.

What’s more, CNC machining prototypes with higher mechanical stability without possible signs of defects. Here are some of the material options commonly used to make CNC prototypes:

- Teflon

- Polymethyl Methacrylate (PMMA)

- ABS

- Bronze

- Titanium

- Steel

- Zinc

- Aluminum

- Copper

- Stainless Steel

Tips and Tricks for CNC Prototype Machining

CNC prototype machining helps designers and manufacturers to ensure that designed parts meet the preferred requirements and are optimized before production starts. Here are some tips to consider for precision prototyping:

Keep Prototypes Less Complex

Keep Prototypes Less Complex

Machined metals are usually suitable for making molds and tools used in die casting and injection molding because metals can withstand higher temperatures and pressure than plastics. Streamlining prototype designs helps to reduce the machining costs of prototypes.

In addition, features such as undercuts and angles require several setups or sophisticated tooling, which can considerably increase the development time and prototype production costs. As a result, before submitting a prototype consider which features are necessary to be included during development and which will increase the price.

Design with Tool Geometry in Mind

CNC machining operations work in a rotary manner, and the axial properties of the cutting tools or the machined parts must be included in the prototype CNC machining. Most cutting tools are circular and have restricted cutting lengths. As a result, all cutting operations will be influenced by the tool’s shape.

Employ Default Tolerances

Tighter tolerances may require the collective use of detailed machining, specialized cutting tools, and extra jigs and fixtures. If tighter tolerances are needed, the design for manufacturing(DFM) can be used to reveal the actual cost of achieving these restrictions. The engineering team could review the tolerance stack to determine if loosening is favorable.

Prototype with an Expert Manufacturing Partner

CNC precision prototyping machining is a pivotal step in the production cycle. As a result, ensure that your part designs are completely optimized before production begins.

More importantly, you should work with a professional prototyping expert. This is because they can take note of the unique geometric requirements of the machining process and work to streamline operations to produce good-quality prototypes. Only then can CNC prototyping prove to be an efficient and fast process for manufacturing the product.

CNC Rapid Prototyping vs. 3D Printing

CNC Rapid Prototyping and 3D printing are practical solutions to various manufacturing demands. However, it is nearly impossible to place one over the other because they both have advantages and disadvantages. Both processes have varying applications and focus and use different technologies.

Part Toughness and Tolerance

CNC prototype machining can create parts with better toughness and tighter tolerances than 3D printing. CNC machines have a tolerance of ±0.01 mm. In contrast, next-level 3D printing technologies like Direct Metal Laser Sintering (DMLS) may only offer tolerances of around ±0.1mm.

Surface Quality

CNC rapid prototyping offers a better surface quality compared to 3D printing due to the extensive tooling that it uses. It uses various tools like a sanding belt, a ball end mill, a face mill, etc., to produce parts with high surface quality.

The layering printing process of a 3D printer forms uneven surfaces giving the workpiece a rough texture. However, you also can treat 3D-printed components with surface finishing methods like plating, powder coating, painting, etc., to produce a smooth surface.

Cost

CNC machines are comparatively costlier than 3D printers due to the need for several accessories such as special cutting tools, fixtures, cutting fluid delivery systems, and more. All these factors further increase the cost of the CNC prototypes.

Material Wastage

The level of material wastage in 3D printing is considerably lower compared to CNC machining. 3D printers use only the required material because it is an additive manufacturing process. In comparison, the subtractive mechanism of the CNC machines cuts excess material and sculpts a block of materials to create desired shapes.

WayKen’s Reliable CNC Prototyping Service

With over 20 years of machining experience, WayKen’s advanced technology allows us to bring your CAD models to life with the best features. We offer professional one-stop CNC prototyping services that can meet from prototyping to full production run.

In addition, we serve different industries with our high-quality prototypes. AutoProtoWay is a sub-website of WayKen Rapid Manufacturing, which is more focused on automotive prototyping and automotive parts manufacturing. Our prototype machining capabilities enable machined high-quality automotive prototypes that match the preferred specification. Just Simply upload your CAD files and get a quote today.

Conclusion

CNC prototype machining helps manufacturers and product designers to achieve the ultimate goal of saving costs and preventing long-term difficulties in manufacturing operations. CNC prototype machining is ideal for creating models with precise and accurate features due to its efficient method and faster cycle times.

FAQs

What are the common industrial applications of CNC machined prototypes?

CNC machined prototypes are used in various industries such as medical, robotics, automotive, electronics, aerospace, etc. These industries rely on CNC prototype machining for high-quality prototypes with high precision.

Is the CNC prototype expensive?

CNC prototyping is a machining model that helps to save the cost of producing functional prototypes. It is important to note that CNC prototype material cost relies on the size of the prototype, and the bigger the prototype size, the higher the cost of the material to create it.

Is CNC prototype machining the best option for prototyping?

When factors such as tight tolerances, good surface finish, or material compatibility are of primary concern, CNC prototyping machining is a better option. However, if cost-effective and low-budget prototyping is a priority, 3D printing may be a better alternative to consider.