In manufacturing, quick results are crucial. From prototype design to final output production, the processes should meet the set deadlines and maintain high-quality standards. Companies involved in research and innovation have developed prototyping technologies such as 3D printing, CNC prototyping, and rapid tooling.

Most industries rely on these high-technology services to fabricate their prototypes. These effective techniques produce accurate parts much quicker while maintaining quality.

Rapid tooling is a vital process in these manufacturing processes. Let’s analyze some of its advantages and industrial application.

What is Rapid Tooling?

Rapid tooling uses technology that enables manufacturers to produce output quickly. A crucial production process, it’s also known as bridge tooling, prototype tooling, or soft tooling.

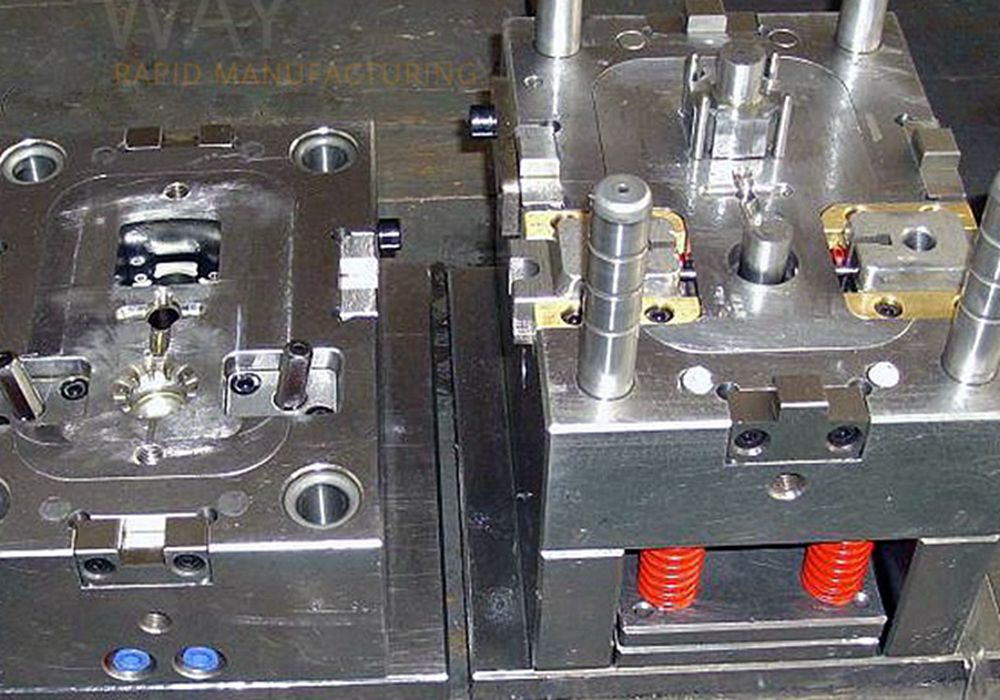

It involves the manufacture of tools used to create injection molds and other custom parts. These tools work well with rapid prototyping.

This technique is essential for testing parts before you finalize the production tooling. Carrying out test production is a cost-effective measure before going into mass production.

Rapid Tooling Industrial Applications

Rapid Tooling Industrial Applications

The rapid tooling process incorporates well in most industrial procedures due to its reliability. How is this process necessary in industrial applications? Let’s take a look.

1. Rapid Injection Molding

This process is the most crucial for rapid tooling in manufacturing. Because of the rapid tooling effectiveness, it’s now helpful in developing molds for commercial purposes. The reliance on this procedure stems from the fact that the production time from start to finish is short.

Company personnel only require the CAD file at the design stage. Rapid tooling requires less time and resources to produce the molds. In the healthcare industry, dentists use dental molds made out of silicone for their patients. Rapid tooling is relied on for this procedure because of its accuracy levels.

Rapid injection molding uses rapid tooling in the creation of plastic parts. When handling plastic-related projects, injection molding produces cost-effective designs that meet client expectations. Companies involved in rapid tooling will guide you on the suitable mold materials, structure and designs.

The injection molding process gauges the impact and any weak parts that need correction before final production. Some of the injection molding parts created via this process are medical syringes, bottle caps, and Lego bricks.

With a prototype, you determine how the parts will work if applied to the actual product. Besides, you also get a clear picture of whether you have used the correct materials.

3. Production of Low-Volume Parts

You can use rapid tooling to develop different designs and parts. It’s instrumental in the production of low-volume parts which are time-sensitive. Clients request a few prototypes and designs before they launch into the market.

4. Test Production Parameters

Manufacturing parts for any industry is expensive. To cut down unnecessary costs, designers and engineers use rapid tooling to check whether the pieces are a good fit. Carrying out this process enables them to identify potential future flaws and plan for redesigns.

Rapid tooling captures the issues in advance and prevents more problems with the final product. This process is cost-effective for both the client and manufacturer.

5. Use in Different Materials

Rapid tooling is classified into either hard or soft tooling. Designers can use various materials during the manufacturing processes, including wood, wax, photopolymers, thermal polymers, composites, metals, and ceramics. You can produce both metallic and non-metallic prototypes using this technique.

Soft tooling is standard with plastics and wax materials used for producing a small batch. On the other hand, for materials such as ceramics and metal, companies can use high-volume production molds. All the parts manufactured from these molds exhibit superior quality and finishing.

Clients who require prototypes can request the rapid tooling company for materials of their choice. The rapid process also allows for trials with the different materials until you get the right one.

Pros of Rapid Tooling

• Cost Savings

All the parts producing during rapid tooling are the same ones to be used in the final production. Once you get results from the testing period, you can use them to improve the product and avoid future losses. The manufacturing process is also fast with a quick turnover, reducing both the client and company’s expenses.

• Time-Saving

The use of high technology allows for the customization of parts during rapid tooling. In a conventional setting, the manufacturer would need to produce the molds, tools, and patterns. However, with rapid tooling, these processes are eliminated, and everything is done within a short time.

Prototypes created are usually accurate according to client specifications. In case there are any changes, the designers modify the item and have a quick turnaround time to maintain a competitive advantage over other companies.

• Chance for Innovation

Rapid tooling provides several opportunities for designers and engineers to make improvements to their prototype development. Compared to conventional tooling, the technical staff is now dealing with more complex designs that require innovation. The constant use of state-of-the-art technology breeds technological advancements.

• Wide Range of Materials

Manufacturers can apply this process to both non-metallic and metallic materials. During the creation of molds, there are more minor limitations for the designers.

The prototype development stage is vital for determining which material is most suitable for the product. If any flaws pop up, the technicians can make changes to the materials before the mass production process begins.

Summary

Rapid tooling is a vital manufacturing process due to its high quality, cost-effectiveness, and quick turnaround time. Most industries require precise parts that meet high levels of accuracy. Whether you need prototypes or low-volume products to test the market, rapid tooling is your go-to for faster results.

For all your trial production needs, you can use rapid tooling services at WayKen to create the best designs. Get a quote today from your manufacturing partner as you scale up your business.