In the whole cycle of automotive product development, the cost of automotive model development stands a small part but it is a key step that directly affects the final market performance of the product. Generally speaking, modeling design starts from product planning, including modeling positioning, sketch design, 3D modeling, prototyping, sample verification, and so on. Let’s talk about each step following.

Step One: From Product Planning to Modeling Positioning

In the early stage of automotive modeling development, it is necessary to conduct market research on the models so as to make targeted planning on modeling positioning. This research includes price, target customer group, competitive models, popular elements, and other aspects. From the product planning, the designer learns that the style positioning and function positioning of the forthcoming modeling, which will help the designer to grasp the direction and make the new modeling as acceptable as possible to the target customer group.

The general layout design is the pre-arrangement of the various parts in the car and the sitting posture of the occupants to meet the functional space requirements and the ergonomic requirements of the drivers and passengers.

Step Two: From Sketch to Effect Diagram

Step Two: From Sketch to Effect Diagram

Both sketches and effect diagrams are two-dimensional designs, which require modeling designers to make creative ideas according to the input conditions at the early stage. Innovative ideas are the key to distinguish one car from another, reflecting different automotive characteristic to attract consumers. The development cycle of a car is relatively long, generally 18-48 months. It will take 2 years at least even if much of the current technological development process can be compressed or omitted. This long period determines that the current look and idea should catch up the fashion from the market in two years at least from now. This requires the designer must have keen modeling observation, judgment, and prediction ability.

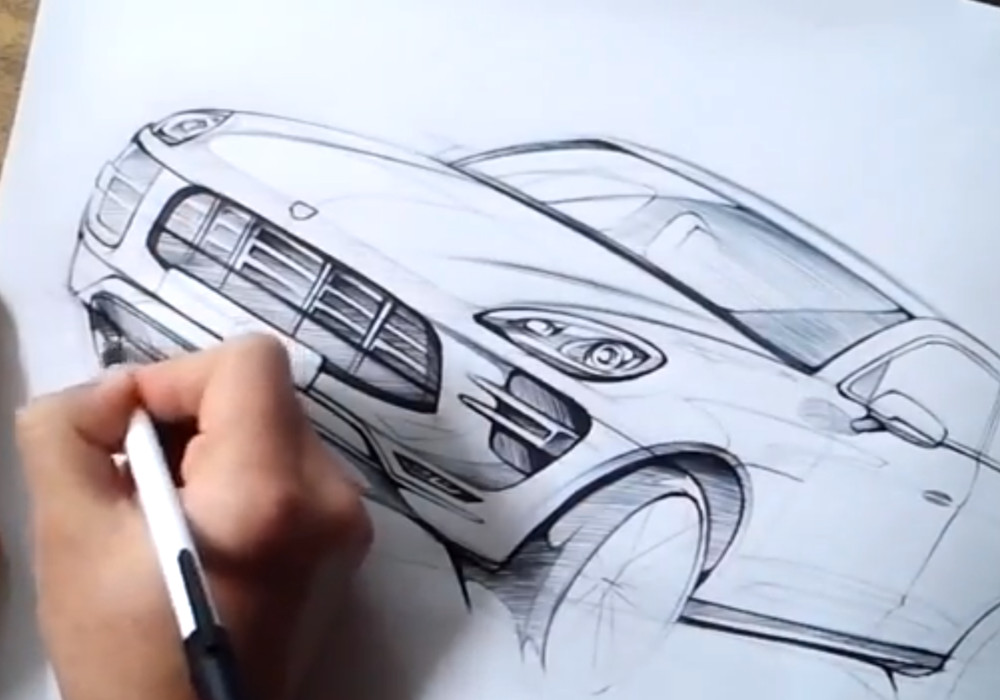

The most direct and rapid means of expressing ideas is sketching, which is the quick expression of a designer’s creative ideas. They could be more casual and relaxing, and their ideas are often novel and unique. At the end of the sketch, there is usually an internal review to select several representative modeling directions for further refinement, namely Effect Diagram.

The effect diagram is used to guide the clay model and digital model, as well as the project presentation. Therefore, it needs to have accurate effects to express proportion, perspective, color, and material. At this stage, the wild ideas in the sketches need to be convergent while factors like the market aesthetics, price cost, policies and regulations, material technology, and so on will play the main role. Effect diagrams are generally divided into the exterior, interior, and detail effect diagrams. Mostly, designers will complete it in computer software so as to improve the work efficiency.

Step Three: Three-dimensional Model

Effect diagrams can be very realistic but many details cannot be accurately reflected. What’s more, effect diagrams are usually more idealized, with a certain degree of subjectivity. After the completion of the effect diagrams, we still need a three-dimensional (3D) model as a basis for deliberation and display modeling.

The 3D model includes a solid model and a digital model. The solid model can be divided into small scale clay model, full-size clay model and resin model according to the process. There are two digital models: the CAS model in the early stage and the A-class model in the later stage.

In practical work, a small proportion clay model is usually made, and the small proportion model is usually 1/4 or 1/2. Small scaled models are more realistic than effect diagram, with more accurate size and scale. The small-scale model requires a smooth and wide curve surface. To make a small scale model, we need to examine each line and each surface repeatedly. Some strong design companies will build a simple mathematical model with the help of 3D modeling software and mill out a clay automotive model through CNC milling, and then finish it with fine scraping. Explore more Custom CNC services here.

After the completion of several small scale models, the preliminary modeling will be determined through a formal modeling review. Then, a full-size (1:1) modeling effect diagram needs to be drawn according to the result of the review. Similarly, the production of a full-size clay model is also very important to the elaboration of the modeling. There is nothing more intuitive and convincing than a model of the same size as the real automotive.

In the following process, the cloud data of scanned points in the automotive clay model will be input into the computer. The common way is to build an A-class mathematical surface according to the clay model. As it will be used for production, the A-class automotive model has more stringent requirements on surface modeling and quality.

In the following process, the cloud data of scanned points in the automotive clay model will be input into the computer. The common way is to build an A-class mathematical surface according to the clay model. As it will be used for production, the A-class automotive model has more stringent requirements on surface modeling and quality.

Step Four: Automotive Prototyping

After class A is finished, a hard model will be created as the original automotive prototype accordingly to close the real automotive as much as possible. Then, with the process of iterative automotive design modification, it comes into the iterative automotive prototyping processes. There are kinds of prototyping technologies, including 3D printing, CNC machining services, vacuum casting, and rapid tooling, to meet different using purposes like engineering verification, functional test, pre-production, marketing tests, etc…

Conclusion

The modeling will not stop until EOL as even after the launch of the show car, the users’ feedback may also bring improvements in the modeling. With the development of computer technology, the automotive modeling process is also updating. For example, “paperless design” and “clay-free design” become popular in recent years. However, no matter how the technology develops, the requirements for automobile modeling designers will never be lowered. Observation, imagination, beauty, sense of space, engineering knowledge, social science knowledge, working skills, sense of responsibility, etc., will always be the required courses for automobile designers.