The backbone of the product development process is creating a reliable mockup, which is a prototype. Because it’s something that never existed before, most of the prototyped parts are custom. One way to produce these engineered parts at least once is through machining. Let’s discuss everything you need to know about prototype machining.

What Is Prototype Machining and Why Use It for the Prototyping Process?

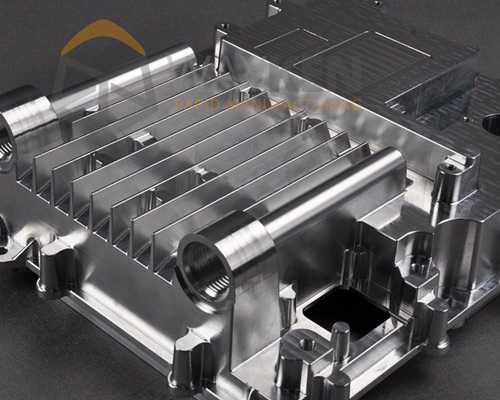

Prototype machining is creating a few functional parts to simulate the functionality and performance before mass-producing the product. The prototyping process requires this step because prototype tests require breaking the elements to their limits most of the time. That is why achieving the peak performance of the product involves machining processes for the prototype.

Factors to Consider in Machining for Prototyping

Factors to Consider in Machining for Prototyping

There are other options aside from machining when creating a prototype. But almost always, the first choice of research and development engineers is machining. Its availability and quality made innovators rely on this process. Here are some factors to consider when opting for machining for prototype parts.

Prototype Design Requirements

As a designer, you need to aim to use standard parts as frequently as possible. Otherwise, you can rely on machining to meet the innovation requirements. When opting for machining, look out for complex geometry, material waste, and machining cost. When you have taken account of those challenges, you can rely on machining for precision, material, size, and consistency.

Machining Processes

Not all machining processes are the same in terms of the capability to create a specific geometry. But when opting for multiple-axis CNC machines, keep in mind that you need to invest more to create an intricate part. You can try designing an assembly if it will not compromise the strength and other critical functionalities.

Machining Costs and Lead Time

Your prototype might need a few unique machined parts more than once. So it’s best to prepare more than one part for your prototype to avoid another process for the replacement. But take note that unused parts will directly increase the lead time and cost of your project.

Bridge for Mass Production

After the success of your prototype, here’s the next step: Mass production. Other processes might replace the machining processes when making large quantities of your customized parts. Ensure that your final product will be cheaper than your prototype. An excellent way to do this is by simplifying the processes to create your custom parts or replacing the process itself.

Advantages of Prototype CNC Machining Services

Prototype CNC machining services have unparalleled reliability even after several similar techniques emerged. As a quick glimpse, CNC machining prototype has the benefits of speed quality and cost-effective solutions for a few hundred parts or less. Here we elaborate on all of those and why engineers still opt for CNC services for their prototypes.

Machining Prototype Parts Is Quick

CNC machine shops typically have the most common prototyping materials in stock. Running the machine to create the prototype parts doesn’t require elaborate preparations. A bottleneck to note for machining is the availability of materials, which the prototype designer can quickly solve using alternatives. Also, keep in mind that hard materials will take more time to machine.

It Has Unparalleled Quality and Consistency

The fame of machining is irreplaceable thanks to its precision. Adding CNC into the process provides unmatched consistency. When your prototype requires both of them, the right machining processes will help you avoid mistakes for your innovation. It is the key to providing the performance and quality that your product needs to provide.

Prototypes Can Benefit from Cost-effective Parts

A machining process has a lower price with fewer production quantities, which prototypes typically need. A couple of custom parts that the designer expects to modify later need the lowest possible price. Machining processes, CNC or manual, will provide the fastest and cheapest way to achieve the desired part quality.

It Can Provide Maximum Precision for Prototypes

Prototypes prove the concept of your product, and some of the functional parts require precision. Achieving this requirement for your prototype is only possible with CNC machining. When the design gets approval, mass production will require the same process with errors reduced to the minimum.

Prototypes Can Use a Wide Range of Materials

An excellent way to cut costs when making prototypes is using widely available materials. Some materials can represent something else in terms of strength and other physical properties. The most common way to shape these materials to the desired geometry is through machining.

Here’s a range of typical machining-friendly materials for your prototypes:

● Aluminum alloys (2024, T6, 7075)

● Stainless steel (303, 304)

● ABS (engineering plastic)

● Acrylic (also known as PMMA)

● Brass

Contact AutoProtoWay.com to discover whether custom CNC machining is the best prototyping solution for your prototyping project.

How To Find a Reliable Company for Your Prototype Machining Services

Prototyping is indeed a costly project for your business. While it’s essential to get the best talents to work on your prototype, it’s also critical for you to find a reliable machining company to create your prototype parts. Here’s a quick guide to help you arrive at an informed decision.

Look for Their CNC Machining Processes Specialization

Aside from those companies with large teams, machining businesses typically don’t have it all. Their teams, from machinists to managers, are all human, with varying skills and expertise. If they are aware of the coverage of their abilities and are upfront about what they cannot offer, they are more likely trustworthy. Of course, you should pick the CNC company with a specialization in prototyping.

Ask for Machining and Shipping Costs

Your project is only as strong as its weakest point: Your budget. You are hesitant to spend a few more thousands of dollars for shipping; that is why you need a company that can provide the best for your budget. Your prototype is only the start of your product’s journey, so doing the budget right will help you stay motivated until it’s ready to market.

Review the Lead Time for Machining and Shipping

The best things take time to get built, but the best companies can do it within a reasonable timeframe. Quantity and material’s physical properties will directly affect the machining time for your prototype. You should choose to deal with the company that provides the lead time breakdown, including the delivery dates.

Get Your Prototype Machining Services Today

Here’s the good news: prototype machining is within your reach. Wayken CNC can help you with your CNC prototyping project. Contact us today to keep your prototyping project running!