CNC robotics machining is a big deal for the manufacturing industry. The robotics industry is growing. According to Allied Market Research, the Robotic industry is worth USD 62.75 billion in 2019. In fact, it’s the future of manufacturing. Since the Covid-19 attack, this industry has been rising exponentially.

The benefits of robotics in manufacturing are many, and the cost benefits are many. In this article, we will explain what CNC robotic machining is and how it is applied.

What is CNC Robotics Machining?

What is CNC Robotics Machining?

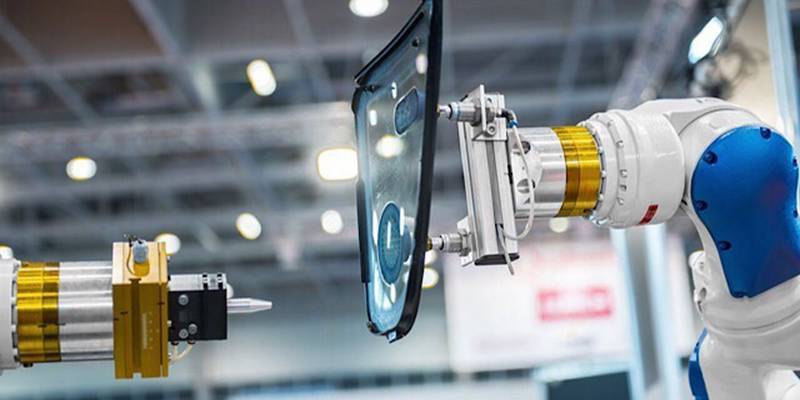

CNC robotics machining is a process that uses computer numerical control (CNC) to operate robotic arms to perform machining operations. Using this process, you can create various materials, including metals, plastics, and composites.

A leading process in automation, CNC machining is extremely popular when dealing with mass production and delivery of quality parts and products for various sectors, including the medical, aerospace, and robotics sectors. This process includes robotics in the CNC machining process and creating robotic parts with the help of CNC machining.

The Benefits of CNC Robotics Machining

When it comes to CNC robotics machining, there are many benefits that make this technology an attractive option for manufacturers. Perhaps the most obvious benefit is the increased accuracy that CNC machining can provide. This is due to the fact that CNC machines are able to operate within very tight tolerances, which is essential for many applications. Let’s discuss the benefits in brief:

1. More Efficiency

1. More Efficiency

The technology behind this robot is based on artificial intelligence and machine learning. These technologies can make decisions about how to handle incoming products and where to send them next. They learn from experience and improve themselves over time.

Automated loading boosts efficiency without you needing to employ additional staff. The robot functions round the clock, with no breaks, sick leaves, or vacations. Automated loading/offloading frees human workers for other, more sophisticated, and creative tasks, such as setting up programming and administration.

2. Improve Speed

Another big benefit of CNC robotics machining is the increased speed at which these machines can operate. This is especially beneficial for high-volume production runs where speed is of the essence. You can also program CNC machines to operate around the clock, which further increases their output.

The robot is faster than humans in many tasks. A recent study found that robots are able to load up to 10 times faster than manual workers. This makes sense since robots don’t have to move around, lift heavy objects, or make repetitive motions. Robots are also better at loading and unloading things like pallets, boxes, and crates.

3. High Accuracy

CNC robotics machining is a process that uses computer-controlled machines to fabricate parts from a variety of materials. This process is extremely precise and can produce parts with intricate designs. Additionally, CNC robotics machining is very versatile you can use them to create parts for a variety of industries, including medical, aerospace, and automotive.

You can pre-program this robotic loader for accurate positioning on each operation. This allows to reach +/- 1mm accuracy in loading and unload operations. It is able to load/unload parts up to 400 kg thanks to the unique design. Moreover, the robots are capable of handling different materials such as metal, plastic, glass, wood, concrete, rubber, stone, ceramic, etc.

4. More Safety

The use of robots to perform tasks that pose a risk to humans is becoming increasingly common. For example, manufacturers use robotics technology in areas where there is a danger of explosion or fire, such as oil refineries, chemical plants, and nuclear power stations. In addition, many companies are developing autonomous vehicles that do not require drivers.

Robots can work in environments where human beings cannot safely operate. They can handle difficult manufacturing processes, such as machining and welding because they are able to withstand extreme conditions that would kill a human worker. Robots can even work in the most hostile environments, such as those containing dust, smoke, noise, heat, or toxic fumes.

5. Multitasking

When it comes to multitasking, robots excel. Humans are limited by their ability to focus on multiple tasks simultaneously. However, robots can complete multiple tasks without any problems.

For example, when a robot picks up items off a production line, it will continue to pick up other items until its arm gets full. It will then pause so that the arm can be reloaded.

Robotic Parts Used in CNC Machining

There are a variety of robotic parts that can be used in CNC machining applications. These parts can include robotic arms, end effectors, controllers, and software. Each of these parts plays a vital role in the overall operation of the CNC machine.

1. Robotic Arms

1. Robotic Arms

Robotic arms can move the various parts of the machine. They are responsible for positioning the cutting tool and workpiece in the correct position. End effectors are responsible for holding the workpiece in place. They can also apply force or torque to the workpiece.

2. End Effector

End effectors are devices that attach to the end of a robot arm, allowing the robot arm to interact with objects and do various tasks. They come in many shapes and sizes, ranging from simple grippers to complex manipulators.

Depending on the material you’re working with, your end effector may require a certain amount of machining before it’s ready for use. Some examples include grabbers, grippers, and suction pumps. However, most end effectors are made of plastic, metal, or composite materials these days.

3. Controllers

The controller is the brain of the CNC machine. It tells the robotic parts what to do and when to do it. They come in many different shapes and sizes, from simple buttons and switches to complex computer systems. The most common type of controller used in CNC machining is a computer numerical control (CNC) system. This type of controller uses a computer to input instructions and operate the machine. Moreover, Controllers are responsible for controlling the various parts of the machine. They ensure that the machine operates correctly and safely.

4. Custom Jigs and Fixtures

Custom jigs and fixtures play an important role in many robot operations by holding parts in place or providing a guide for locating parts in space. Using jigs and fixtures, CNC machines can create parts and components of virtually any size or shape. In many cases, robotic parts used in CNC machining help to improve the accuracy and speed of the manufacturing process.

The Different Types of CNC Robotics Machining

There are several different types of CNC robotics machining, each of which has its own advantages and disadvantages.

The three most common types of CNC robotics machining are:

The three most common types of CNC robotics machining are:

Spindle-based machining: In this type of machining, the robot’s arm is mounted on a spindle, you can use them to operate the machine tool. Spindle-based machining is generally more accurate than other types of CNC robotics machining, but it is also more expensive.

Gantry-based machining: In this type of machining, the robot’s arm is mounted on a gantry, which is a type of framework that supports the arm and allows it to move in a linear fashion. Gantry-based machining is less accurate than spindle-based machining but is less expensive.

Cartesian-based machining: In this type of machining, the robot’s arm is mounted on a cartesian coordinate system, which allows for three-dimensional movement. Cartesian-based machining is the most versatile and can be used to create parts with complex shapes.

Each type of CNC robotics machining has its own advantages and disadvantages, so it is important to choose the right type for the job at hand. In general, spindle-based machining is more accurate but more expensive, while gantry-based machining is less accurate but less expensive. Cartesian-based machining is the most versatile but also the most expensive.

Robots vs. CNC Machines: How They Stack Up?

1. Workspace

1. Workspace

The largest workspaces are found in factories where the production volume is high. Here, the biggest machines are used. These include lathes, milling machines, and drilling machines. Electric motors usually drive them.

In contrast, small workshops use smaller machines such as grinding machines, polishing machines, welding machines, and cutting machines. Their drives are typically hydraulic or pneumatic.

A huge advantage of industrial robots is that you can easily expand the workspace. For example, you can simply attach another arm to the end of the existing arm. This way, you can increase the maximum reach of the robot considerably.

2. Versatility

Robots are probably the best example of what makes them such versatile tools. They are capable of performing many different tasks. For instance, you could use a robot to cut out a piece of wood, turn it into a vase, assemble it onto a shelf, and even put some flowers inside. All of these processes require different types of movements.

3. Affordability

Robots are often considered too expensive for small businesses. But there are many reasons why you might want to consider investing in one. Robots don’t require special skills to operate and can work 24/7 without requiring much maintenance. They are also versatile, meaning they can handle a wide range of tasks. And because you can program them to do almost anything, it’s possible to automate repetitive processes, such as drilling holes or cutting slots.

Get CNC Machining Robotic and Automation Parts at WayKen

As technology advances, so does the machinery used in many industries. One such industry is robotics. Robotics gradually changing the manufacturing process, making it faster and more efficient. As a result, the use of robotics is indispensable in the manufacturing industry.

One type of robot that is becoming increasingly popular in manufacturing is the CNC robot. Custom CNC machining can be used not only to make create robot parts but also to work with robots.

So, if you are thinking of using CNC machining robotics and creating robotic and automation parts, you can consider working with a company with years of experience and finished by skilled engineers and workers.

WayKen is the perfect company for you. we offer high-quality robot parts and machining services at an affordable price. With over 20 years of experience and 100+ skilled workers, we confidently make sure you can get the products that meet your needs. Don’t hesitate. Get a free quote today!