These technologically reliant times require the auto parts manufacturing industry with enormous supply. Factories need to keep up with the supply chain’s demands, helping transportation and personalization reach their standards.

That is why their designers and engineers resorted to rapid prototyping, effectively changing everything in the automotive industry. They became aware of its benefits, contributing to its increasing popularity. Let’s have an overview of how this manufacturing process defined the modern field of vehicle manufacturing.

Why Rapid Prototyping Influences the Auto Parts Manufacturing Industry?

Prototyping is a vital element of the design and engineering process. The automotive parts manufacturing industry is not an exemption. But the advantages of rapid prototyping, such as having affordable quality and quick lead time, greatly influence this field. Here is an overview of why engineers and designers prefer rapid prototyping

Advancing Technology

Advancing Technology

The automotive industry has continuously rising standards. It’s becoming easier to pinpoint the root cause of road accidents, including faulty parts. Around 1.35 million people dying each year from road crashes demanded the mandatory quality development of automotive parts. Rapid prototyping is a quick and efficient process that can help manufacturers keep up with this demand.

Design Flexibility

Creating flexible designs is one of the hurdles for automotive engineers. They need to comply with regulations from several countries and the personal needs of customers. They demand safety features, personalization, or even vehicle autonomy. It created a trend of preparing compliant yet personalized parts, which rapid prototyping performs best.

Customization Demands

Rapid prototyping is arguably the cheapest method to produce a few functional parts with intricate details. The automotive industry needs this feature because the increasing number of customers has unique part design demands. In case that there are customers that demand similar designs, rapid prototyping can quickly create cost-effective solutions for both sides of the deal.

Advantages of Using Rapid Prototyping to Manufacture Auto Parts

Rapid prototyping redefined the meaning of affordable auto part manufacturing. Receiving custom yet compliant car parts within weeks became achievable since the dawn of this manufacturing process. Below we discuss the reasons why it happened.

Affordable Quality

Rapid prototyping uses the lowest cost of high-quality materials, mainly aluminum and engineering plastics. It can produce repeatable intricate designs for low volume demands. Another good thing is its manufacturing speed, which can only take weeks rather than months for other manufacturing processes.

Easy to Innovate

Car manufacturers can make bridges for mass production after perfecting rapid prototyping designs. In case it doesn’t happen yet, it only needs a lower cost than other processes to make modifications. Revision of CAD models, reprogramming or creating new tooling only takes hours or days rather than weeks or months.

Effective and Efficient Part Design

Several advanced prototyping methods of rapid prototyping include 3D printing, rapid injection molding, or custom CNC machining. In some instances, a single company can use all of these methods to create functional assemblies that vehicles need.

Safety

Automotives have excessive numbers of moving parts. At least one of them failing can pose a high risk of an accident. That is why car manufacturers resort to the most adaptive method to create these parts with the highest quality, rapid prototyping.

Availability

Compared to other manufacturing processes, rapid prototyping is arguably the fastest method to create compliant car parts. It also uses the most resourceful material available, making the process have few instances of shortage.

What Parts are Possible to Create And Develop Using Rapid Prototyping?

Vehicle manufacturers create around 13,400 cars everyday. But constant development requires them to have unique parts. That is why creating a few functional auto part prototypes is necessary, leaving no choice for designers other than rapid prototyping.

Interior Parts

Car owners want to see their ownership of their vehicle. It requires manufacturers to produce custom parts with a unique appearance within a small time frame. While interior features mostly have decorative purposes, rapid prototyping can provide intricate designs that comply with quality standards.

Exterior Parts

Exterior Parts

While automotive only have few items residing on the exteriors, their exposure to elements requires them to have high-quality materials. Examples are the exterior lights and headlights, and customizing them alone needs engineers to rely on rapid prototyping

Functional Parts

Developing functional car parts is a demanding task for manufacturers. That is why they need to perform quick runs and short-term trial productions. Using rapid prototyping processes such as injection molding and rapid tooling, they can analyze the performance helping them innovate their existing products.

How to Use Rapid Prototyping to Manufacture Auto Parts?

Making custom auto parts using rapid prototyping sounds exciting for car owners and manufacturers alike. But what portions of this process make it unique? Here we discuss how rapid prototyping produces customized car parts.

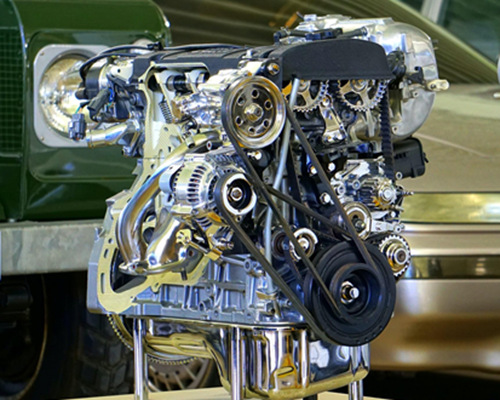

Engine Parts Using Aluminum Machining

Design mockups and functional versions of automotive engine parts are becoming cheaper, thanks to rapid prototyping. The use of aluminum has been widespread because it is lightweight, has high heat transfer, and low cost.

Lighting Parts Using Acrylic Machining

Acrylic is a type of clear resin that can withstand the elements while retaining its transparency. It’s easy machinability and durability add to its physical properties that make it perfect for automotive lighting. Rapid prototyping can bring out the best of this material while keeping the quality at a low cost.

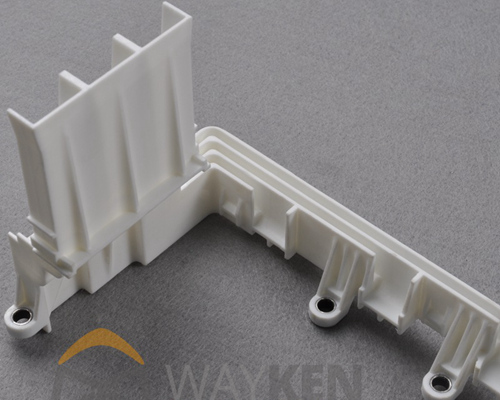

Part Prototypes Using Injection Molding and Rapid Tooling

Automotive parts typically have intricate designs. A few reasons are comfortability for interiors, aerodynamic stability for exteriors, and safety for functional details. A quick way to make batches enough for the supply chain is using injection molding and rapid tooling.

Start Taking Advantage of Rapid Prototyping for Auto Parts Manufacturing

Hopefully, this article made you more aware of how rapid prototyping helps develop the auto parts manufacturing industry. Read our other blogs to learn more about rapid prototyping. We are happy to touch bases by contacting us through our website: https://autoprotoway.com/ if you want to start utilizing this cost-effective process for your automotive company today. In addtion to rapiding prototyping technologies, here are other cost-effective methods such as Custom CNC, rapid tooling, vacuum casting, 3D printing and etc. If you want to know us more, please don’t hestitate to contact us.