The automotive industry is constantly evolving. There are new car models, and car parts are continually being upgraded. Aluminum car parts are a great way to make your car stand out from the crowd and be more efficient, too.

Aluminum is one of the most abundant elements on earth, but it’s also one of the most challenging to work with. How do you work with aluminum? How to make alum auto parts? Aluminum car parts manufacturers use unique technology for these. Let’s discover this in detail.

How to Manufacture Aluminum Car Parts

There are many ways to manufacture metal auto parts. Some of them are very expensive, while others are cheaper. Depending on your budget and needs, you may choose one method or another.

For example, if you need to produce large quantities of aluminum car parts, you will probably need to invest in a CNC milling machine. You could opt for a laser cutting machine if you just need a few pieces.

CNC machining for Aluminum Car Parts

CNC machining for Aluminum Car Parts

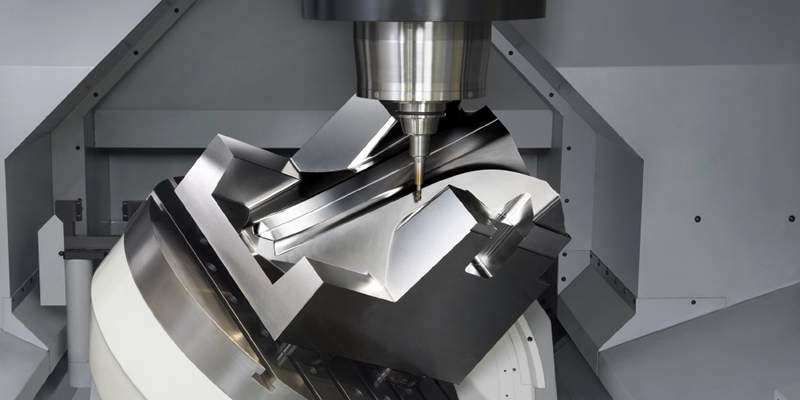

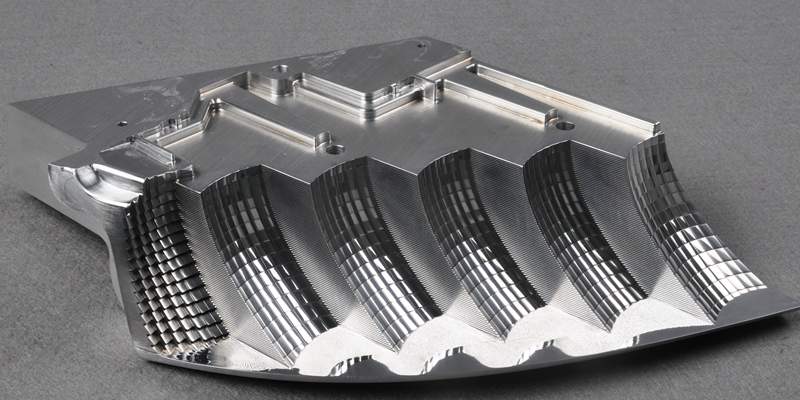

CNC Machining is an automated method of manufacturing metal parts using Computer Numerical Control (CNC) technology. CNC machining allows us to create complex shapes and features in our metal parts at very high speeds.

We can also cut materials like aluminum with CNC aluminum machining. CNC machining offers several advantages over manual processes. First, we can achieve higher accuracy and repeatability. Second, we can reduce cycle time and increase productivity.

But it is an expensive way to manufacture alum auto parts. Therefore, you should only choose these for vast quality, reducing your per part cost.

Aluminum Die Casting

Die casting is an industrial manufacturing technique that involves pouring liquid metal into a mold cavity at very high pressures. Once the metal cools, the mold opens, and the part is ready for removal. Die casting is used in many industries, including automotive, aerospace, medical devices, consumer goods, electronics, toys, sporting equipment, etc. There are several different types of dies depending on what type of product is being manufactured.

Aluminum 3D Printing

3D printing is an additive manufacturing process that creates three-dimensional objects using layers of material. It is commonly used to print plastic models, but it can also be used to print metals like aluminum.

Metal 3D printing uses lasers to fuse together tiny amounts of powdered metal. A laser beam heats the surface of the object until it melts the metal particles together. Once the molten metal cools, it hardens into a solid form.

The finished product is usually more robust than other types of 3D printing because the metal is fused together instead of just bonded. Mainly this technique is used for prototypes and external body parts.

Why are Aluminum Car Parts Different From Other Metal Auto Parts

There are a few reasons aluminum car parts are different from other metal auto parts. Aluminum has some unique properties that made this different from other metals. Aluminum increases your car’s performance and makes the car lightweight which increases fuel efficiency. Let’s discover individual characteristics.

1. Strength

1. Strength

Aluminum is more substantial than steel because it doesn’t break down as steel does. Steel becomes brittle at low temperatures, while aluminum stays tough even when cold. This makes aluminum ideal for building aircraft, cars, appliances, and even skyscrapers.

2. Flexibility

Aluminum is one of the strongest materials known to man, able to withstand extreme temperatures and pressures. But it is also very flexible, making it ideal for applications where durability isn’t essential. This makes aluminum perfect for use in everything from aircraft parts to bicycle frames.

The metal’s combination of strength and flexibility is what gives it its name — “aluminum.”

3. Malleability

Aluminum is one of the most malleable metals known. It can be extruded into almost any desired shape by passing aluminum through a die. This makes aluminum ideal for manufacturing parts such as automotive body panels, aircraft fuselages, and architectural components. It can also be formed into complex shapes by bending and shaping processes.

4. Conductivity

Aluminum is an excellent conductor of both heat and electricity. A typical household wire contains about 18% aluminum. However, achieving the same electrical conductivity takes around 50 times more weight. This is because aluminum is much lighter than copper. In fact, an aluminum conductor weighs around half of a copper conductor with the same electrical conductivity, according to the American Society for Testing Materials (ASTM).

5. Corrosion resistance

Aluminum is a lightweight and corrosion-resistant material. It has been used in the automotive and aerospace industries for decades, offering a high strength-to-weight ratio and excellent fatigue properties. Aluminum has become a common material for cars because it’s lightweight, strong, durable, and affordable.

Common Aluminum Alloys Materials in Car Parts

Cars consist of mostly 30,500 parts, including their outer panel. Aluminum alloy is an excellent material for making cars because of its rust resistance and lightweight. There are many different types of aluminum alloys used for making cars. Some examples include:

- Aluminum Alloy 1100 series

- Aluminum Alloy 4032

- Aluminum Alloy 3105, 3003, and 3004, series

- Aluminum Alloy 2024 series

- Aluminum Alloy 5005, 5182, 5083, 5052, and 5251

- Aluminum Alloy 6022, 6061, 6181, and 6016

- Aluminum Alloy 7046 and 7003

The Benefits of Aluminum Auto Parts

Aluminum auto parts are a great way to save money on your car repairs and keep your vehicle running smoothly. They’re also environmentally friendly since they don’t rust as other metals can. Here we have listed all the benefits that Aluminum auto parts.

1. Performance

1. Performance

The automotive industry is changing rapidly. New materials, such as aluminum, are being used to build lighter, stronger vehicles. Aluminum is typically between 10% – 40% lighter than steel. Its strength makes it possible to use thinner panels and fewer structural members. Aluminum’s flexibility enables firms like Ford Motor Company to develop automobile forms that fit into tight spaces, such as around the cockpit area.

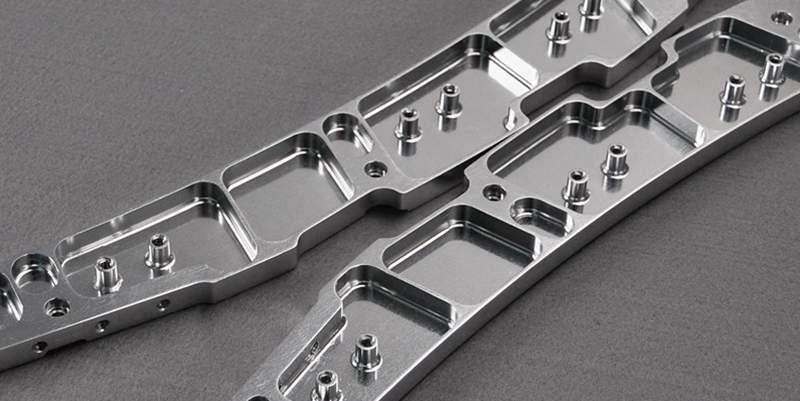

2. Precision and Repeatability

Aluminum is a very soft metal. And you can use various methods to work with aluminum depending on your requirements. As it is a soft metal it is easier to maintain the precision of the car parts. Also, aluminum alloys are excellent for repeatability. It is easier to make highly precise and repetitive car parts with aluminum alloy.

3. Safety

Today, aluminum makes up about half of the body panels of every vehicle sold in America. The material offers many advantages over steel. For instance, aluminum can withstand twice as much impact energy as steel of the same strength. In addition, aluminum absorbs more crash energy than steel because it expands during deformation.

4. Durability

Aluminum car parts require less corrosion and have a longer life span than steel parts. This makes aluminum parts ideal for cars operating in harsh environments, such as off-roading or military applications. The durability and longer life span of aluminum car parts make cars an excellent investment.

5. Fuel efficiency

If we compare aluminum car parts with steel car parts then you will find aluminum is 24% less weight than steel. The automotive industry is now looking into ways to make even better use of the material, such as adding it to the body panels of vehicles, making parts thinner, and developing new materials that could help improve fuel efficiency.

6. Resilient and light-weight

6. Resilient and light-weight

Aluminum is often seen as being weak and brittle, but it actually has superior properties compared to steel. This is because aluminum atoms are arranged in a hexagonal crystal structure rather than a solid one. Because of this, it is much stronger than steel and lighter too. In fact, about 70% of the world’s cars use aluminum today, mainly due to its strength and low weight.

7. Flawless Functionality

The aluminum industry has been making strides toward improving the quality of its products over the last few decades. In recent years, improvements in technology and materials have enabled manufacturers to make connections that are stronger, lighter, and easier to assemble. This has resulted in better product durability and functionality. As a result of the advances being made, the number of applications for aluminum connecting has increased dramatically.

Applications of Aluminum Car Parts

There are uncountable applications of aluminum car parts. We have accumulated some of those here:

There are uncountable applications of aluminum car parts. We have accumulated some of those here:

- Aluminum wheels

- Mirrors

- Valve covers are made of aluminum

- Engine blocks

- After-market auto parts

- Aluminum transmission housings

- Wheel spacer Parts

- Ornaments and Logos

- Aluminum brackets

- Carburetors Housings

- Impellers and fan clutch Parts

- Air filter adaptors

- Aluminum handles

- Alternator housings

The Trend of Aluminum in Cars

The aluminum industry is constantly evolving and growing. One trend that is already underway is the use of aluminum in electric vehicles. Electric vehicles are becoming increasingly popular, and as battery technology continues to improve, they are only going to become more common. Aluminum is a great material for electric vehicles.

Another trend that is likely to continue is the use of aluminum in hybrid vehicles. Hybrid vehicles are becoming more popular as people look for ways to save fuel and reduce their emissions. Aluminum is also a great material for hybrid vehicles.

So, what does the future hold for aluminum in cars? It is likely that we will see more and more aluminum being used in electric and hybrid vehicles, as well as in safety-critical components. This is good news for aluminum car parts manufacturers.

Conclusion

As you have seen, aluminum car parts are durable and long-lasting. The best part is that they provide the car with a modern look.

In case you are looking for aluminum car parts manufacturers, WayKen is always your best choice. We offer a variety of CNC Machining capabilities including 3, 4, and 5-axis machining. There also have a broad range of materials available such as aluminum, steel, titanium, plastics, and more.

Our experienced engineers and advanced types of equipment enable us to fulfill precision and high-quality automotive parts orders. From individual test prototypes to small production parts, we are ready to assist you. Get a free quote today!

FAQs

What car parts are made of aluminum?

There are many car parts that are made of aluminum. These parts include the engine block, cylinder heads, intake manifold, exhaust manifold, and transmission case. The use of aluminum in these parts helps to reduce the overall weight of the vehicle, which improves fuel efficiency

Is it expensive for aluminum car parts?

Aluminum car parts are not expansive because they are made from recycled materials. The price of aluminum car parts depends on how much scrap metal is available. If there is a lot of scrap metal, then the price of aluminum car parts will be lower.

What grade of Aluminium is used for car bodies?

The grade of aluminum used for car body panels depends on the vehicle manufacturer. Most manufacturers use high-strength aluminum alloy 6061 T6 for the front fenders, hoods, doors, trunk lids, roof rails, and other parts where they need extra strength. Other grades include 7075, 7074, and 2024.