At first, car prototyping seems like a service that is useful only to those large companies that produce cars. Such as Toyota or Audi. However, automotive prototyping is a much more common feature that can be used both by professional companies and individual enthusiasts. We decided to write a car prototyping guide to mention all the things you didn’t know or misunderstood about the process.

Why Car Prototyping Is Absolutely Necessary

Let’s see why car prototyping is such an important feature and let’s look at who can benefit from automotive prototyping services. You see, vehicles seem like something everyday and mundane. However, they are very complex from a technical point of view. The internal combustion engine enclosure is one of the hardest cast parts to produce. Car pistons must withstand little explosions during the combustion phase and work for years. The chassis is to withstand all the mass of the car and the passengers encountering road bumps and turns at over 100 km per hour. And most importantly, even the seemingly insignificant things, like car lights, influence the safety of human life inside. You would definitely want to foolproof those elements before you issue them. Otherwise, and this has happened before, you’d have to call all the things you’ve worked hard to design and manufacture back. Now, car elements have complex geometry and high quality. It is best to be sure they work before producing them.

Who Can Benefit From Automotive Prototyping

Car manufacturers are not the only people who produce car parts. There are literally tens of thousands of post market companies that produce enhancement components or spare parts. For example, there is a wide range of companies who adapt pickups and trucks to an offroad environment. And the parts they produce must be waterproof, dustproof etc. Let’s take a snorkel, a pipe that allows intake of air when the car is partially submerged underwater. It is vital to check that the design is waterproof, otherwise the customer would take in water and he won’t trust that company ever again.

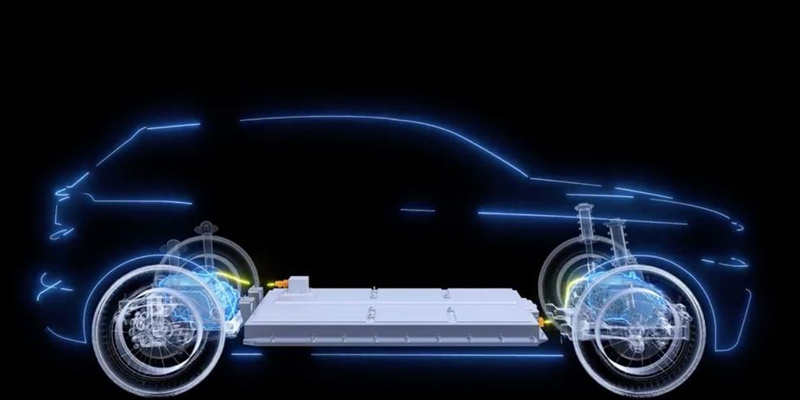

Other people that can address the car prototyping services are individuals who are passionate about improving their cars or startups who want to test out their innovative tech. They are developing something completely new in the majority of cases so they can’t be sure it will work at all.

Which Car Elements Must Be Prototyped

The best course of action, of course would be to prototype every new component, however, that is not economically viable. So, we have listed some custom car parts that should be prototyped to make sure that they will not fail.

Those include:

Performance parts: intake manifolds, pistons, brake disks, brake pads, steel or aluminum car wheels, suspensions, shock absorbers, exhaust pipes, valves, wheel spacers and radiators.

Lighting parts: lenses, fog light bulbs systems, side indicator, brake, reverse lamps, reflectors,

Aesthetic elements: windshields, deflectors, wing mirrors, door handles, front gauge panels, steering wheels, grilles and wheel caps.

Special items: Custom offroad accessories such as snorkels and wheel covers, car spoilers, customized bumpers and car plate lighting.

The last area is actually very wide and would depend upon the imagination of the developer. There are lots of cars that have been tuned with original items so much, you can’t tell their original model.

Types Of Prototypes Useful in the Automotive Industry

There are two types of prototypes used in the automotive industry: Proof-Of-Concept prototypes and Design Validation. If you are making an automotive prototype, you’d probably be making at least the second type. However, some serious developers make both. Let’s see what the prototype types are about and when they are useful.

Proof-of-Concept Prototypes of Automotive Parts

Proof-of-Concept car prototypes are developed at initial stages of design,where only an idea is formed but you are not completely sure that the solution will work. PoC prototypes are usually simplified and look like something made in a garage. That is because you don’t want to waste a lot of resources on them. You just have to check if the idea works at all. That’s why PoC prototypes usually consist of standard parts as far as possible and use the cheapest materials and technologies. A lot of people build them themselves, but in case of custom car elements, it may be beneficial to contact professionals because they already have a stash of standard elements and some cheap rapid prototyping tools. You won’t have to bother looking for those and buying them from various suppliers.

Prototypes for Efficiency and Design Validation

Design validation prototypes are created to be as close to final design as possible. The materials used and the production techniques are as close to the end part as possible too. Basically it’s the same part but not yet optimized for mass production. Design validation prototypes are much more expensive and require serious professional preparation and manufacturing. It is advisable to be sure of your design before making them. For individual enthusiasts such prototypes may become the end part. But for companies, there is more work to be done regarding mass production technology optimization.

Overview of Car Prototyping Techniques

Just a decade ago, car manufacturing was strictly mass production with lots of efficient production lines, but low flexibility. Today, we can find lots of flexible rapid manufacturing technologies for single part production and low batch manufacturing. Let’s look at the rapid prototyping techniques available for manufacturing custom car parts.

Car Prototyping with Injection Molding

Injection molding has long been considered a mass production process. However, modern CNC milling machines and EDM machining technologies brought it to the prototyping realm. You can now produce and injection mold tooling in literally a week. That can be achieved through using softer materials like aluminum and separate simultaneous manufacturing of the cavities and the other elements of the mold. Injection molding is the slowest and the least flexible process among the rapid prototyping but it yields plastic parts of excellent quality.

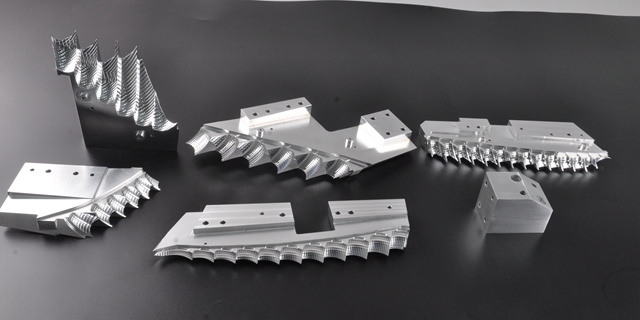

Car Prototyping with CNC Machining

CNC machining is perfect for performance parts because it is the only process that will provide you with high-quality, high-precision, low surface finish metal car components. The good part is that modern 5-axis CNC machines can manufacture almost any geometry but it takes some time to prepare the NC program. However, once prepared, you can use the same program to manufacture multiple identical parts. It’s an easily scalable process.

Get to know more our CNC machining capabilites for your CNC machining project.

Car Prototyping and 3D-printing

3D-printing is the best process for single part production. It is the fastest and the most flexible technique you will meet on the market. However, the surface finish and the precision is not as good as injection molding. We suggest you make small auxiliary parts and enclosures for additional gauges and sensors. They don’t need to be very strong or aesthetic but they will be cheap and they will do the job. If you are looking for some complex futuristic design of the performance parts, you may consider metal 3D-printing but it is generally more expensive than CNC machining nowadays.

Sheet Metal Parts Prototyping

Sheet metal production of automotive custom components is useful for car body parts. As we all know, the body consists of sheet metal fixed to the frame. If you really want to replace some of the body patches, you’ll need to address sheet processing manufacturers. They have special CNC bending machines and rolling devices, although they will often need to produce a wooden master-model to bend the sheet to. That returns you to CNC machining.

Small Batch Manufacturing for Automotive Prototyping

Small batch manufacturing is a service that is offered by the rapid prototyping shops as well. Due to the fact that a lot of prototyping techniques are scalable to some degree ( such as CNC machining and injection molding), ordering a small batch of prototype parts from a single manufacturer will turn out at a cheaper price per part. And small batches are absolutely important for performance parts because you may want to conduct different test runs. Some of them will render the part unusable. So, it is a great idea to pack up a number of identical prototypes from the start.

Learn more about the low volume production at AutoProtoWay, our engineers are dedicated to supporting you through the whole prototype to producting process.

Another case where small batch manufacturing is useful refers to startups who are only entering the market. You may want to produce a limited batch and see how it sells. If the batch is sold out well, then you can start mass production. Or perhaps time is of the essence and you want to start selling your idea before your competitors but the mass production line is still in preparation. Then, you can order a first limited edition and start the sales before full scale production is fine-tuned.

Conclusions

As you can see, car prototyping is not such a complex process and it can be useful for everyone. There are lots of prototyping techniques for every budget and timeline. If you have plans to create some improvement to the modern automotive systems, we strongly suggest you think about prototyping and small batch manufacturing. Vehicle safety strongly influences the lives of both the drivers and the pedestrians.