We will do your auto part prototypes quickly, effectively, and at a reasonable cost, without compromising the quality whatsoever. Your requirements are our guiding factor.

Reasons for Prototype Auto Parts Manufacturing

There are several reasons why you are considering your automotive prototype. These may include:

- To evaluate and test your design.

- To clarify costs and other issues in production.

- To sell the product to other companies.

- To develop the processes and techniques necessary to manufacture the part(s) effectively and low cost.

This is pre-production or short-run production of parts. If this is in the automotive industry, then we say it is prototype auto parts manufacturing.

The automotive industry is an ever-changing industry due to the dynamics when it comes to the needs of customers. As a result, manufacturers must keep improving their designs to stay competitive in the ever-changing market. This makes prototyping of auto parts an unavoidable endeavor.

The Common Automotive Parts Prototypes

The main components of a car are shown in the figure below:

Consequently, the main auto parts to be prototypes include;

- Chassis components – Engine block, transmission system, brakes, axles, tires, the frame, and so on.

- Power train components – Torque converter or flywheel, transmission, driveshaft, suspension, and the wheels and so on.

- Interior components – A, B, C & D Pillars, Air Vents & Ducts, Arm Rests, Central Control Panel, Consoles, Dashboards, Door Panels, Speaker Grilles, Steering Wheel, Switch Plates, Trim Pieces, among others

- Exterior components – Bumper, Chrome Trim, Door Handles, Emblems & Plates, Fenders & Fender Liners, Fog Lamps, Grilles & Grille Covers, Headlights, Mirror Housings & Mounts, Spoilers & Air Dams, Taillights, Trunk Lids among others.

- Functional parts – Air Components, Air Filter Housing, Battery Components, Engine Cover, Fuel Tanks, Shifting Device Lid, etc.

The idea is to be able to prototype as many automotive parts as possible, thus fasten the development as well as the production of vehicles. Prototyping comes with ease of assembly.

Available Technologies in Automotive Part Prototyping

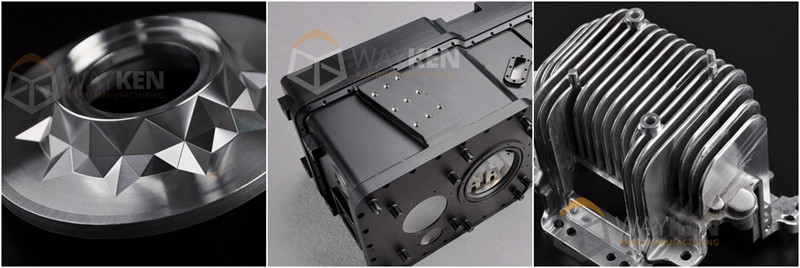

There are several technologies associated with the automotive industry when it comes to parts prototyping. They include;

- 3D printing – Additive manufacturing technologies for generating 3D models from CAD models. They include SLA, FDM, SLS, and EMB among others.

- custom CNC machining – Use of CNC machines such a CNC lathe, CNC, milling, CNC plasma, CNC laser, etc.

- Forging – Technology to shape metal using localized compressive forces using dies or a hammer. Include cold forging, hot forging, or warm forging as may be required by the client.

- Low volume injection molding using state of art machines.

- Rapid aluminum tooling – Automotive has many aluminium parts. As a result, it is necessary to invest in rapid aluminium tooling to meet the demand.

- Sheet metal processing – There is a great need to have many sheet metal processes due to varied shapes found in the automotive industry. such may include forging, forming, 3D printing, and so on.

- Vacuum casting – Given the large number of automotive parts made from elastomers, vacuum casting is very important in prototype auto parts manufacturing. And so is an investment in an effective vacuum casting technology.

The list is long. You probably have to make an inquiry and the right advice shall be delivered by the experienced team.

Available Post-Processes for Automotive Part Prototypes

Finishing is a very important step in the manufacturing of automotive parts. This is due to the high requirements for safety, aesthetics, corrosion resistance, tarnish resistance, removal of burrs and other flaws, wettability, wear resistance, to improve the tolerances, and so on. Different technologies are applied in different prototype materials. Some of the key finishing processes/technologies include;

- Anodic oxidation – This is the use of electrochemical methods to form an oxide film on metal surfaces.

- Chrome plating – A process of forming a thin layer of chrome on metal surfaces using electroplating.

- Painting – Application of paints, pigments, or color on surfaces. Different machines/methods can be used in painting.

- Polishing – Creating a smooth and/or shiny surface by rubbing it with another material or by use of chemical actions. Polishing can make a surface shiny and thus reflective while in some materials, it can be used to diffuse reflection.

- Lapping – This is a process of rubbing two surfaces together with an abrasive material placed between the two surfaces. It is most applicable where the surfaces had been ground or fine-tuned.

- Honing – Honing is a process where an abrasive grinding stone or grinding wheel is used to scrub a surface through a controlled path. It produces a precise surface. Sometimes, honing can be used as a manufacturing process rather than a finishing process.

- Trimming – This especially for plastic parts that are molded. Hand trimming and/or machine trimming are applicable.

- Assembly – Some parts constitute small parts that need to be assembled by experts by using other machines such as robots.

This list can be endless given the complexity of automotive parts and never-ending technological advancements.

Conclusion

The pre-production prototype step is very crucial in the automotive industry. It yields the following results;

- Knowhow about the manufacture-ability of the product/part

- Parts’ maintainability and reliability

- A list of components as well as the materials

- Plans for field support once the parts are deployed

- Costs related to the installation and production of the parts

- Factors related to safety and environment

- Meeting the regulatory requirements

- Production time schedules

This far, you already know how important is the prototype auto parts manufacturing in the automotive industry. You also know the main parts of the automotive as well as some of the prototyping technologies. It is important to note that automotive parts are complex and require excellent finish due to complex customer needs. As a result, expert advice and experience are very important to maintain the quality of such parts. Additionally, investment in modern technologies cannot be avoided. At AutoProtoWay.com (WAYKEN RAPID MANUFACTURING LIMITED), we have assembled just the right technical team to make sure all your prototype auto parts manufacturing needs are met. We have also invested in the state of art technologies making us the preferred partner when it comes to automotive parts prototyping needs. Our experience stands in the market based on the customers we have supported over the last 20 years of our existence. We look forward to having you onboard.